22

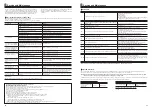

(a) For insertion, push on the SD memory card until it clicks into place.

(b) For ejection, push on the SD memory card until it clicks.

Note:

Logos

Capacities

2 GB to 32 GB *2

SD speed classes

All

5.6 Using SD memory card

<Handling precautions>

Manufacturer

Model

Tested in

Silicon Power

SP004GBSDH004V10

Jan. 2015

Before using a new SD memory card (including the card that comes with the

unit), always check that the SD memory card can be safely read and written to

by the FTC controller.

<How to check read and write operations>

a) Check for correct wiring of power supply to the system. For more details,

refer to section 4.5.

(Do NOT power on the system at this point.)

b) Insert an SD memory card.

c) Power on the system.

d) The LED4 lamp lights up if the read and write operations are successfully

completed. If the LED4 lamp continues blinking or does not light up, the

SD memory card cannot be read or written to by the FTC controller.

(a)

(b)

7KH6'/RJRLVDWUDGHPDUNRI6'&//&

7KHPLQL6'ORJRLVDWUDGHPDUNRI6'&//&

7KHPLFUR6'ORJRLVDWUDGHPDUNRI6'&//&

*1 To edit main controller settings or to check operating data, an Ecodan

service tool (for use with PC) is required.

$*%6'PHPRU\FDUGVWRUHVXSWRGD\VRIRSHUDWLRQORJV

(1) Use an SD memory card that complies with the SD standards. Check that the

SD memory card has a logo on it as those shown on lower right figure.

(2) SD memory cards to the SD standards include SD, SDHC, miniSD, micro SD,

and microSDHC memory cards. The capacities are available up to 32 GB.

Choose that with a maximum allowable temperature of 55ºC.

(3) When the SD memory card is a miniSD, miniSDHC, microSD, or micro SDHC

memory card, use an SD memory card converter adapter.

%HIRUHZULWLQJWRWKH6'PHPRU\FDUGUHOHDVHWKHZULWHSURWHFWVZLWFK

The cylinder unit is equipped with an SD memory card interface in FTC.

Using an SD memory card can simplify main controller settings and can store

operating logs. *1

(5) Before inserting or ejecting an SD memory card, make sure to power OFF the

system. If an SD memory card is inserted or ejected with the system powered

ON, the stored data could be corrupted or the SD memory card be damaged.

*An SD memory card is live for a short duration after the system is powered

off. Before insertion or ejection wait until the LED lamps on the FTC control

board are all off.

(6) The read and write operations have been verified using the following SD

memory cards, however, these operations are not always guaranteed as the

specifications of these SD memory cards could change.

(7) Make sure to follow the instruction and the requirement of the SD memory

card’s manufacturer.

(8) Format the SD memory card if determined unreadable in step (6). This could

make it readable.

Download an SD card formatter from the following site.

SD Association homepage: https://www.sdcard.org/home/

(9) FTC supports FAT file system but not NTFS file system.

(10) Mitsubishi Electric is not liable for any damages, in whole or in part, including

failure of writing to an SD memory card, and corruption and loss of the saved

data, or the like. Back up saved data as necessary.

(11) Do not touch any electronic parts on the FTC control board when inserting or

ejecting an SD memory card, or else the control board could fail.

To avoid cutting fingers, do not touch sharp edges of the SD

memory card connector (CN108) on the FTC control board.

CN108

System Set Up

5

Note: Before inserting or ejecting an SD memory card, confirm that the power supply

earth cable is securely connected and prevent the FTC from being applied with

static electricity (e.g. touch a case body etc.). Otherwise, it may cause a failure of

the FTC due to the static electricity.

23

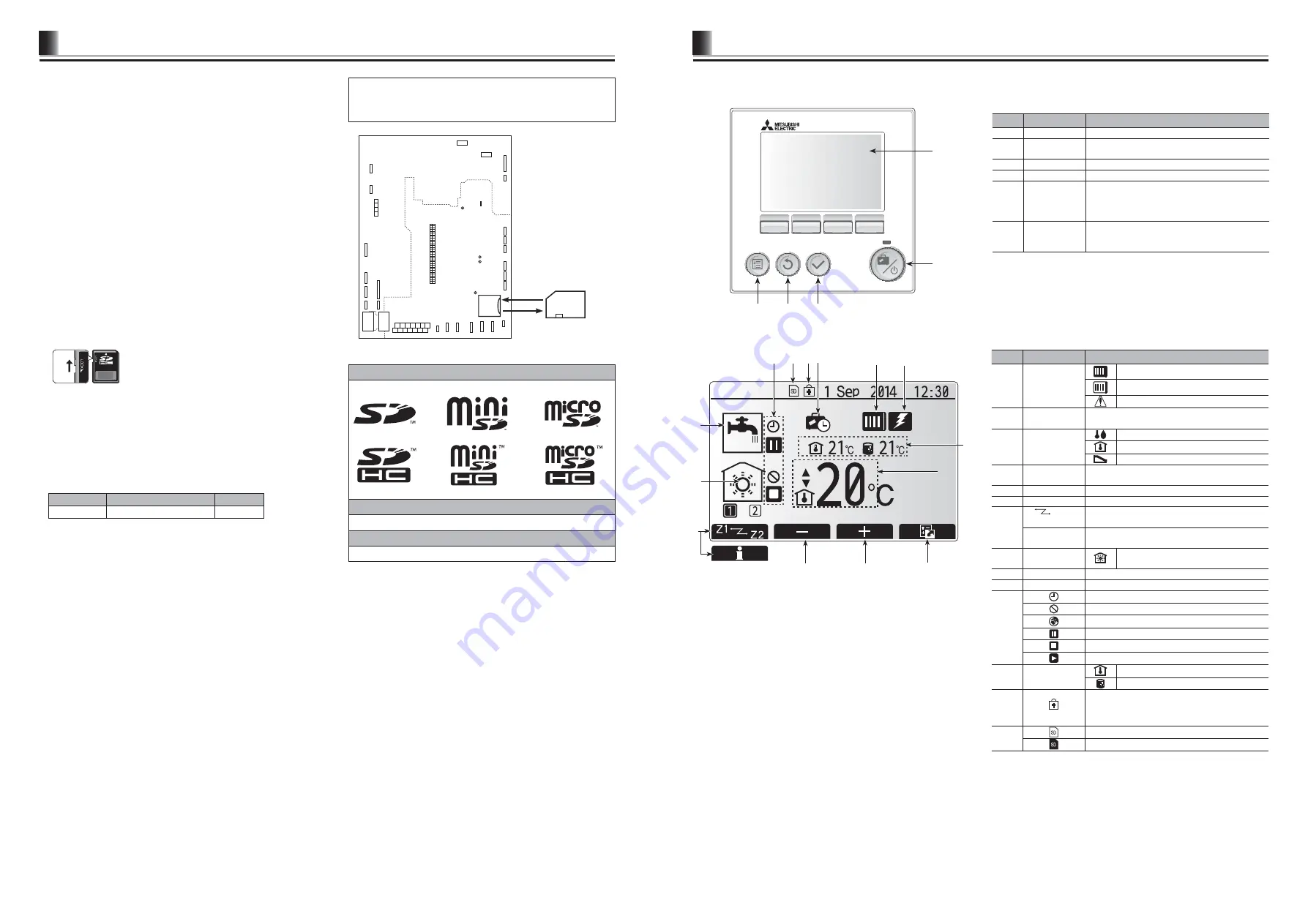

F1

F2

F3

F4

B

C

D

E

A

5.7 Main Controller

<Main controller parts>

Letter

Name

Function

A

Screen

Screen in which all information is displayed

B

Menu

Access to system settings for initial set up and

modifications.

C

Back

Return to previous menu.

D

Used to select or save. (Enter key)

E

Power/Holiday

Confirm

If system is switched off pressing once will turn

system on. Pressing again when system is

switched on will enable Holiday Mode. Holding the

button down for 3 secs will turn the system off. (

*1

)

F1-4

Function keys

Used to scroll through menu and adjust settings.

Function is determined by the menu screen visible

on screen A.

*1

When the system is switched off or the power supply is disconnected, the

cylinder unit protection functions (e.g. freeze stat function) will NOT oper-

ate. Please beware that without these safety functions enabled the cylinder

unit and installation may potentially become exposed to damage.

System Set Up

5

Main screen

<Main screen icons>

Icon

Description

11

10

2

1

9

6

5

4

14 13

12

7

1

Heat pump

‘Heat pump’ is running.

Defrosting.

Emergency heating.

2

Electric heater

When this icon is displayed the ‘Electric heaters’

(booster heater) are in use.

3

Target

temperature

Target room temperature

Target flow temperature

Compensation curve

4

OPTION

Pressing the function button below this icon will dis-

play the option screen.

5

+

Increase desired temperature.

6

-

Decrease desired temperature.

7

Z1

Z2

Pressing the function button below this icon switches

between Zone1 and Zone2.

Information

Pressing the function button below this icon displays

the information screen.

8

Space heating

mode

Heating mode

Zone1 or Zone2

9

DHW mode

Domestic hot water heating mode

10

Holiday mode

When this icon is displayed ‘Holiday mode’ activated.

11

Timer is activated.

Prohibited

Server control is activated.

Stand-by

Stopped

Operating

12

Current

temperature

Current room temperature

Current water temperature of thermal store tank

13

The Menu button is locked or the switching of the

operation modes between DHW and Heating opera-

tions are disabled in the Option screen.(

*2

)

14

SD memory card is inserted. Normal operation.

SD memory card is inserted. Abnormal operation.

*2 To lock or unlock the Menu, press the BACK and CONFIRM keys

simultaneously for 3 seconds.

3

8