1

4.4. Connecting the thermistor cables

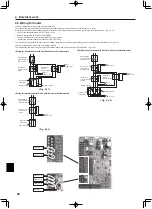

Connect the thermistor for the FTC4 (Master) controller.

For multiple outdoor units control with FTC4 (Slave), see section 9.

4.4.1 Connecting the room temp. thermistor (TH1) cable

TH1 is an optional part (PAC-SE41TS-E).

TH1 is required to use the auto adaptation function. However, when room tempera-

ture detection is conducted by the main controller or the wireless remote controller

(optional), this part is not required.

Connect the TH1 cable to the CN20 connector on FTC4 (Master).

When the TH1 cable is too long, bundle the excess cable outside the FTC4 (Master) unit.

For more details, refer to Section 4.3 in this manual or the installation manual that

comes with PAC-SE41TS-E.

When using TH1, place this sensor on appropriate location to detect room temperature.

4.4.2. Connecting the refrigerant pipe temp. thermistor (TH2) cable

Connect the TH2 cable to the CN21 connector on FTC4 (Master).

For split Outdoor unit : Connect TH2.

For packaged Outdoor unit : It is NOT necessary to connect TH2.

When the TH2 cable is too long, bundle the excess cable outside the FTC4 (Master) unit.

Do not bind the wires in the FTC4 (Master) unit.

<Thermistor position>

Place TH2 on

refrigerant

piping (

liquid

side).

It is recommended to protect the thermistor with heat insulating materials so as not

to be affected by ambient temperature.

Note: Be sure to place TH2 where it correctly detects refrigerant piping temp. (liquid side).

Because;

(1) TH2 is required to detect heating subcool correctly.

(2) Refrigerant temperature of water-to-refrigerant heat exchanger also needs

to be detected for protection purpose.

4.4.3.

Connecting the flow water temp. thermistor (THW1) cable

and the return water temp. thermistor (THW2) cable

The THW1 and the THW2 cables share a connector, and the connector connects to

CNW12 connector on FTC4 (Master).

When the THW1 and THW2 cables are too long, bundle the excess cables outside the FTC4 (Master) unit.

Do not bind the wires in the FTC4 (Master) unit.

<Thermistor position>

Place THW1 on

water

piping (water

outlet

side) after booster heater, and THW2 on the water inlet side.

It is recommended to protect the thermistor with heat insulating materials so as not to be affected by ambient temperature.

Note: Be sure to attach THW1 where it correctly detects Flow temp. (water oulet side). Fore more details, see Page 6.

4.4.4. Connecting the actual DHW tank thermistor (THW5) cable

Connect the THW5 cable to the CNW5 connector on FTC4 (Master) if the DHW tank is available.

When the THW5 cable supplied with FTC4 (Master) is too long, bundle the excess cable outside the FTC4 (Master) unit.

Do not bind the wires in the FTC4 (Master) unit.

<Thermistor position>

Place THW5 on the position where tank water temperature can be detected correctly.

It is recommended to position the thermistor at the mid height of the DHW tank (to control DHW heating with this sensor).

It is recommended to protect the thermistor with heat insulating materials so as not to be affected by ambient temperature.

Especially for double (insulated) tank, thermistor should be attached to the inner side (to detect the water temperature).

Note:

Connect the terminals by using the ring terminals and also insulate the cables of adjoining terminals when wiring to TBI.1 or 2.

The necessary thermistor (THW, THW, THW, THW) connection for 2-zone temperature control, refer to “4. Wiring for 2-zone temperature control” .

The necessary thermistor (THWB1, THWB2, THW, THW) connection for back-up operation of boiler, refer to the installation manual of PAC-TH011HT-E .

Caution:

Do not route the thermistor cables together with power cables.

The sensor part of the thermistor should be installed where user can not access.

(It should be separated, by supplementary insulation, from areas the user can access.)

4. Electrical work

<Fig. 4.4.1>

TBI.2 THW6

TBI.2 THW7

TBI.2 THW9

TBI.2 THW8

TBI.2 THWB1

TBI.2 THWB2

Connector CNW5

Connector CNW12

Connector CN21

Connector CN20