0

Local application factors

* This FTC4 is designed to connect Mr.Slim/Ecodan inverter outdoor unit of MITSUBISHI ELECTRIC to local systems. Please check the following when designing the lo-

cal system.

* MITSUBISHI ELECTRIC does not take any responsibility for the local system design.

Heat exchanger

(1) Withstanding pressure

Designed pressure of outdoor unit is 4.15 MPa. Following must be satisfied for burst pressure of connecting application.

Burst pressure: More than 12.45 MPa (3 times more than designed pressure)

(2) Performance

Secure the heat exchanger capacity which meets the following conditions. If the conditions are not met, it may result in malfunction caused by the protection opera-

tion or the outdoor unit may be turned off due to the operation of protection system.

• In case of hot water supply, condense temperature is less than 58 °C in max. frequency operation with the outside temperature 7 °C D.B./6 °C W.B.

(3) Heat exchanger internal capacity

Heat exchanger internal capacity must be within the capacity range shown below. If the heat exchanger below the minimum capacity is connected, it may result in the

back flow of liquid or the failure of the compressor.

If the heat exchanger above the maximum capacity is connected, it may result in the deficiency in performance due to lack of refrigerant or overheating of the com

-

pressor.

Minimum capacity: 10 × Model capacity [cm³] / Maximum capacity: 30 × Model capacity [cm³]

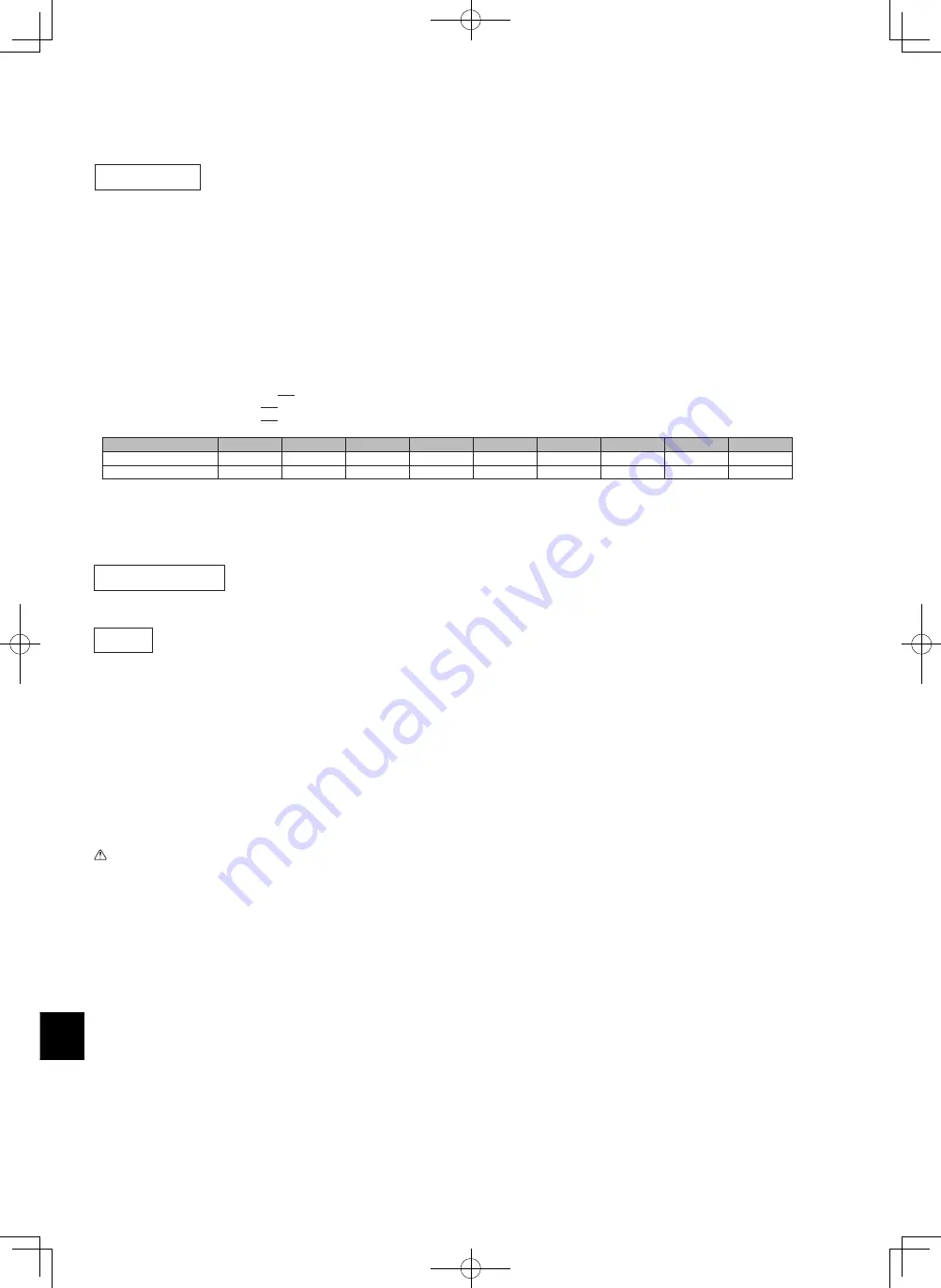

e.g. When connecting to PUHZ-HRP

100

VHA

Minimum capacity

: 10 ×

100

= 1000 cm³

Maximum capacity

: 30 ×

100

= 3000 cm³

Model capacity

35

50

0

1

100

125

140

200

250

Maximum capacity [cm³]

1050

1500

1800

2130

3000

3750

4200

6000

7500

Minimum capacity [cm³]

350

500

600

710

1000

1250

1400

2000

2500

(4) Contamination maintenance

1. Wash the inside of heat exchanger to keep it clean. Be sure to RINSE not to leave flux. Do not use chlorine detergent when washing.

2. Be sure that the amount of contamination per unit cubic content of heat transfer pipe is less than the following amount.

Example) In case of

[

9.52 mm

Residual water: 0.6 mg/m, Residual oil: 0.5 mg/m, Solid foreign object: 1.8 mg/m

Thermistor position

Refer to 4.4.

Notes

· Install the hydraulic filter at the water inlet pipework.

· Inlet water temperature of heat exchanger should be within the range 5 °C - 55 °C.

· Water quality should be to European Directive 98/83 EC standards

pH value of 6.5 - 8

Calcium ≤ 100 mg/L

Chrorine ≤ 100 mg/L

Iron/Manganese ≤ 0.5 mg/L

· Refrigerant pipe diameter from outdoor unit to refrigerant-water HEX (Only for SPLIT type)

Use the pipe with same diameter size as the refrigerant pipe connection diameter of outdoor unit. (Refer to outdoor unit installation manual.)

· Ensure that there is sufficient anti-freeze chemical in the water circuit. It is recommended to use 7 : 4 anti-freeze to water ratio.

· The water velocity in pipes should be kept within certain limits of material to avoid erosion, corrosion and excessive noise generation.

Be aware, and take care of , that local velocities in small pipes, bends and similar obstructions can exceed the values above.

e.g.) Copper: 1.5 m/s

Warning:

· Always use water that meets the above quality requirements. Using water that does not meet these standards may result in damage to the system pipework

and heating components.

· Never use anything other than water as a medium. It may cause a fire or an explosion.

· Do not use heated water that is produced by the air to water heat pump directly for drinking or cooking. There is a risk to damage your health. There is also

a risk that installing the water heat exchanger may corrode if the necessary water quality for air to water heat pump system cannot be maintained. If you

wish to use the heated water from the heated pump for these purposes, take measure such as to the second heat exchanger within the water piping sys

-

tem.