255

2

P

ARAM

ETE

R

PARAMETER

(2) Control method switching by external

terminals (RT signal, X18 signal)

1) FR-A700 series

The switching of the control method (V/F control,

Advanced magnetic flux vector control, Real

sensorless vector control and vector control) by the

external terminal may be made in either of the

following two ways: switching by the second function

selection signal (RT), or V/F switching signal (X18).

Two types of control method can be switched with the

RT signal by setting the type of motor to be used as

second motor in [

Pr. 450 Second applied motor

] and

control method of the motor in [

Pr. 451 Second motor

control method selection

]. Turn ON the RT signal to

select the second function. Other second function is

also made valid.

For switching by the X18 signal, setting [

Pr. 81

Number of motor poles

= 12, 14, 16, 18, 20] and turning

the X18 signal ON switches the currently selected

control method (Advanced magnetic flux vector

control, Real sensorless vector control or vector

control) to V/F control. In this case, use this signal

only for changing the control method of one motor

since second function as electronic thermal relay

characteristic, etc. can not be changed. (Use the RT

signal to change the second function.)

For the terminal used for X18 signal input, set 18 in

any of [

Pr. 178 to Pr. 189 Input terminal function

selection

] to assign the function.

2) FR-E700, D700 series

To change the control method (V/F control to

Advanced magnetic vector control or General

purpose vector control) with an external terminal, use

V/F switch signal (X18).

Turning X18 signal ON switches control from

Advanced magnetic vector control or General-

purpose magnetic vector control to V/F control.

For the terminal to input X18 signal, assign the

function by setting "18" to any of [

Pr.178 to 184 Input

terminal function selection

].

Switch the control method using external terminal

(X18 signal) during an inverter stop. If control method

between V/F control and General-purpose magnetic

flux vector control is switched during the operation,

the actual switchover does not take place until the

inverter stops. In addition, if control method is

switched to V/F control during the operation, only

second function becomes valid as V/F control and

second functions are selected simultaneously in V/F

control.

(3) Switching the control method from the

external terminal (MC signal)

When [

Pr. 800 = 12, 2

] and [

Pr. 451 = 12

], speed

control is selected when the control mode switching

signal (MC) is OFF, and torque control is selected

when the signal is ON under Real sensorless vector

control or vector control. Switching between speed

control and torque control is always enabled

independently of whether the motor is at a stop or

running or the DC injection brake operation (pre-

excitation).

Under vector control, speed control/position control

switchover and torque control/position control

switchover can be made by setting [

Pr. 800

= 4, 5].

Speed control/position control switchover and torque

control/position control switchover is made when

frequency decreases to or below the [

Pr. 865 Low

speed detection

] setting.

For the terminal used for MC signal input, set 26 in

any of [

Pr. 178 to Pr. 189 Input terminal function

selection

] to assign the function.

When an analog input terminal (terminal 1,4) is used

for torque limit, torque command, etc., terminal

functions also switch if control mode is switched.

For the terminal function in different control modes,

refer to page 43.

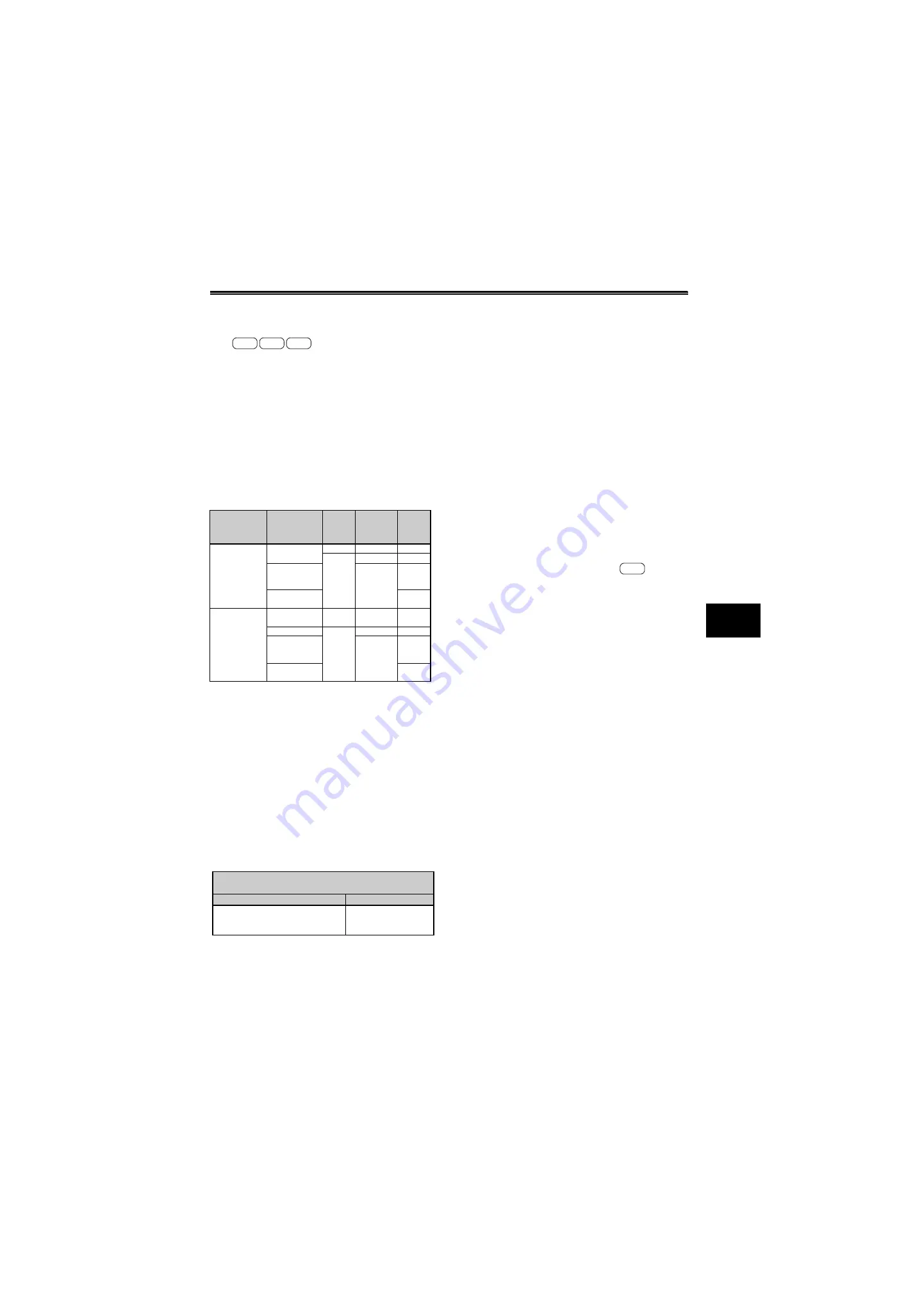

First Motor

Control Method

(RT signal-OFF)

Second Motor

Control Method

(RT signal-ON)

[

Pr. 450

]

Setting

[

Pr. 453

] and

[

Pr. 454

]

Setting

[

Pr. 451

]

Setting

V/F control

V/F control

9999

—

—

Other

than 9999

9999

—

Advanced

magnetic flux

vector control

Other than

9999

20, 9999

Real sensorless

vector control

10 to 12

Advanced

magnetic flux

vector control

Real sensorless

vector control

Vector control

Same control as

the first motor *

9999

—

—

V/F control

Other

than 9999

9999

—

Advanced

magnetic flux

vector control

Other than

9999

20, 9999

Real sensorless

vector control

10 to 12

* V/F control is selected when "12, 14, 16, 18, 20" is set in

[

Pr. 81

] and the X18 signal is ON. When the X18 signal is

not assigned, turning the RT signal ON selects V/F control

as the RT signal shares this function.

First motor control method ([

Pr. 80 = Motor capacity

],

[

Pr. 81 = 12, 14, 16, 18, 20

])

X18 (RT) signal-OFF

X18 (RT) signal-ON

Advanced magnetic flux vector control

Real sensorless vector control

Vector control

V/F control

A700

E700

D700

A700

Summary of Contents for FR-A700 Series

Page 245: ...279 2 PARAMETER PARAMETER MEMO ...

Page 440: ...474 PARAMETER MEMO ...

Page 522: ...556 SELECTION MEMO ...