372

PARAMETER

z

Execution of auto tuning

When performing PU operation, press

of the

operation panel.

For External operation, turn ON the start command

(STF signal or STR signal). Tuning starts. (Excitation

noise generates at this time.)

Since the RUN signal turns ON when tuning is

started, caution is required especially when a

sequence which releases a mechanical brake by the

RUN signal has been designed.

During offline auto tuning, the following I/O signals

are the only valid signals (in the initial setting.)

It takes approximately 9s to complete the tuning.

• To force tuning to end

Enter signal to terminal MRS or RES, or press

during the PU operation mode. In the External

operation mode, enter signal to terminal MRS or

RES, or turn OFF the starting switch (STR or STR

signal) to end the operation.

After tuning is completed, check [Pr.96] setting.

• Ended properly...............3 or 103 is displayed.

• Ended in error ................One of 8, 9, 91, 92, and 92 is

displayed.

When offline auto tuning ends, press

of the operation

panel during PU operation. For External operation, turn

OFF the start signal (STF signal or STR signal) once.

This operation resets the offline auto tuning and the PU's

monitor display returns to the normal indication.

(Without this operation, next operation cannot be started.)

When tuning ends in error, auto tuning is not performed

properly, so the frequency search gain is not set. Perform

inverter reset (

refer to page 57

), and re-do the tuning.

When using the motor corresponding to the following

specifications and conditions, reset [

Pr. 9 Electronic thermal

O/L relay

] as below after tuning is completed.

(a) When the rated power specifications of the

motor is 200/220V(400/440V) 60Hz, set 1.1

times rated motor current value in

Pr. 9

.

(b) When performing motor protection from

overheat using a PTC thermistor or motor with

temperature detector such as Klixon, set "0"

(motor overheat protection by the inverter is

invalid) in

Pr.9

.

The motor constants measured once in the offline auto

tuning are stored as parameters and their data are held

until the offline auto tuning is performed again.

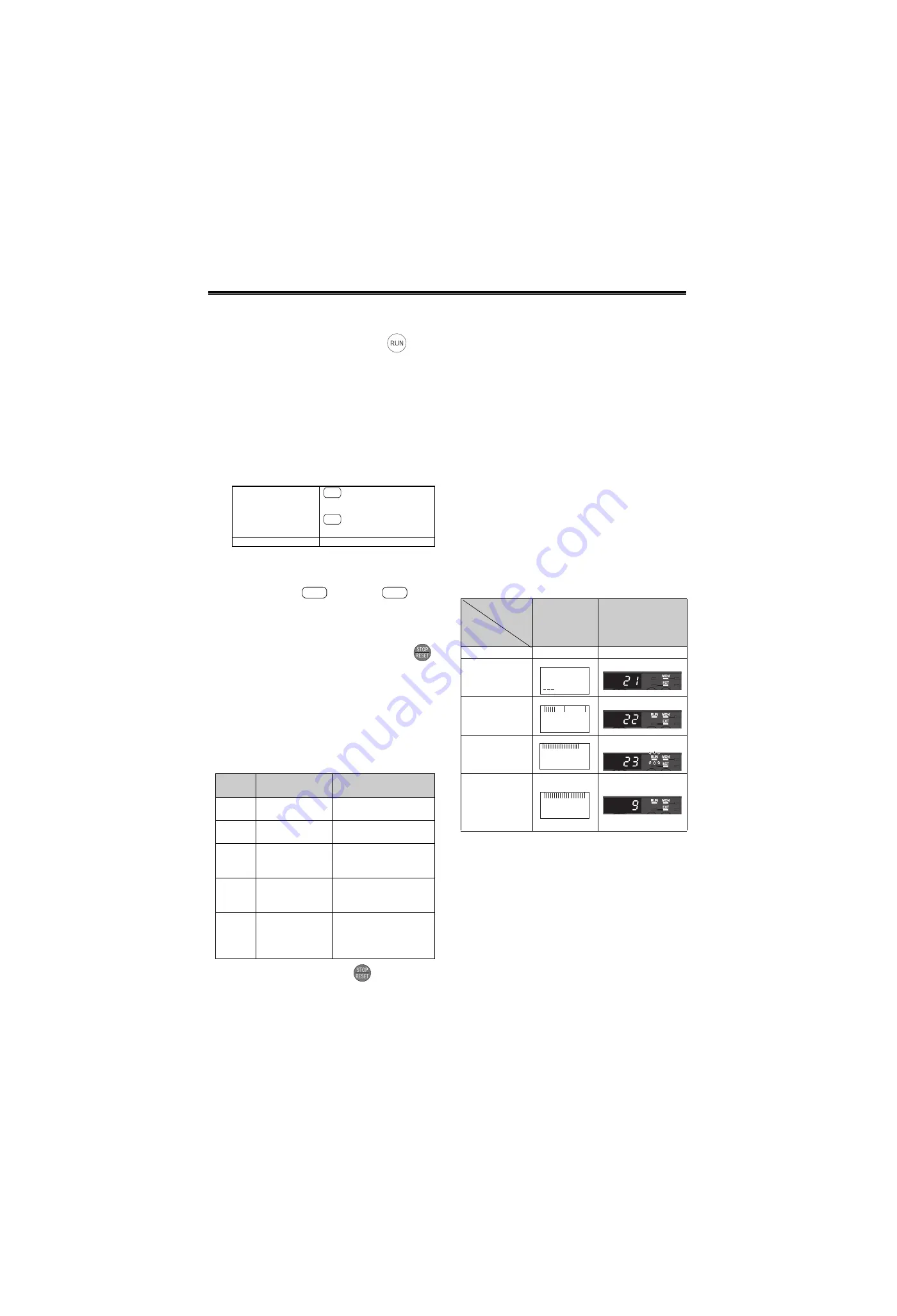

Monitor is displayed on the operation panel and parameter

unit (FR-PU04, FR-PU07) during tuning as below.

Input terminal

<Valid signal>

MRS

,

RES

,

STF

,

STR

STF

,

STR

Output terminal

RUN

,

FM

*

,

ABC

* When terminal FM is assigned to output the output

frequency and speed, progress status of offline auto

tuning (full scale when ended properly) is output

(eight levels for

, five levels for

).

Error

Display

Error Cause

Countermeasure

8

Forced end

Set "21" in

Pr. 96

and

perform tuning again.

9

Inverter protective

function operation

Make setting again.

91

Current limit (stall

prevention) function

was activated.

Set acceleration /

deceleration time longer.

Set "1" in

Pr. 156

.

92

Converter output

voltage reached

75% of rated value.

Check for fluctuation of

power supply voltage.

93

Calculation error

A motor is not

connected.

Check the motor wiring and

make setting again.

Set the rated current of the

motor in

Pr . 9

.

E700

D700

E700

D700

Parameter

Unit

(FR-PU04, FR-

PU07)

Operation Panel

Indication

Pr. 96

setting

21

21

(1) Setting

(2) Tuning in

progress

(3) Normal end

(4) Error end

(when inverter

protective function

operation is

activated)

STOP PU

21

READ:List

FWD PU

22

STF

TUNE

STOP

PU

23

STF

TUNE

COMPLETION

Flickering

STOP PU

9

STF

TUNE

ERROR

Summary of Contents for FR-A700 Series

Page 245: ...279 2 PARAMETER PARAMETER MEMO ...

Page 440: ...474 PARAMETER MEMO ...

Page 522: ...556 SELECTION MEMO ...