488

SELECTION

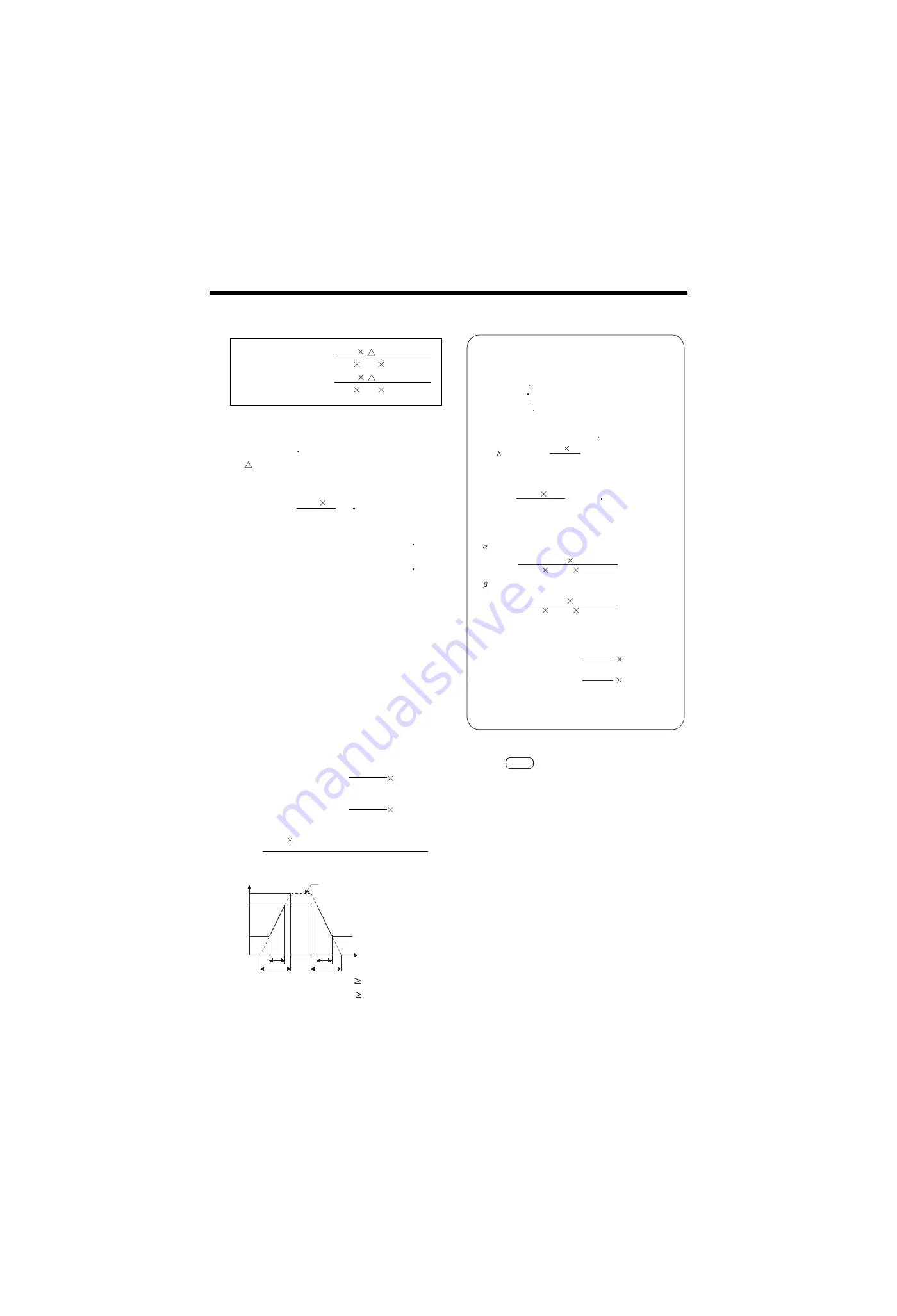

1) Formula for calculating the acceleration and

deceleration times (simple method)

where,

J

T :

All J = motorJ

M

+ loadJ

L

(converted to an equivalent JM at the motor

shaft) [kg m

2

]

N:Difference between motor speeds before and

after acceleration/deceleration N

1 -

N

2

[r/min]

T

M:

Rated motor torque

T

L

max:Maximum load torque (converted to an

equivalent JM at the motor shaft) [N m]

T

L

min: Minimum load torque (converted to an

equivalent JM at the motor shaft) [N m]

α

a: Acceleration torque coefficient

*

β:

Brake torque coefficient regenerative braking

torque

*

P: Rated motor torque [kW]

N: Motor synchronous speed at 60Hz [r/min]

2) Calculation and setting example of the

acceleration and deceleration times ([

Pr. 7, Pr. 8

])

Set the time to accelerate/decelerate using

acceleration/deceleration reference frequency

([

Pr. 20

]) as reference in acceleration/deceleration

time ([

Pr. 7, Pr. 8

]). Use "tas" and "tds" found in 1)

to calculate the acceleration and deceleration

times ([

Pr. 7, Pr. 8

]) at shortest acceleration/

deceleration time as follows:

Acceleration time ([

Pr. 7

])

ta

Deceleration time ([

Pr. 8

])

td

When fast response is required, set the smallest

value of which the formula is satisfied. And when

soft acceleration / deceleration is required, set

the required time.

(3) When there is a limit on acceleration

time

When acceleration time exceeds the required value,

select either Advanced magnetic flux vector control

or Real sensorless vector control, increase torque

boost, or select an inverter larger in capacity to

increase the inverter current overload capacity at

acceleration. Or, select a motor larger in capacity

(select an inverter larger in capacity also) to increase

the motor acceleration torque.

Shortest

acceleration time

tas =

J

T

N

[s]

9.55

(T

M

α

a-T

L

max)

Shortest

deceleration time

tds =

J

T

N

[s]

9.55

(T

M

β

+ T

L

min)

T

M =

9550

P

[N m]

N

* Refer to the Technical Note No.30 (data part)

Acceleration time ([

Pr. 7

]) =

N

tas

N

1

- N

2

Acceleration time ([

Pr. 8

]) =

N

tds

N

1

- N

2

N =

120

Acceleration/deceleration

reference frequency ([

Pr. 20

])

Number of motor poles

Speed at the output of

Acceleration/deceleration

reference frequency ([

Pr. 20

])

N

2

N

1

tas

tds

ta

td

N

0

Speed

[Example 2] Calculated in the conventional unit system

A conveyor is driven by the SF-JR 2.2kW 4P motor and

FR-A720-2.2K inverter (V/F control).

Suppose that

(When the acceleration/deceleration reference

frequency is the initial setting of 60Hz.)

From Technical Note No. 30 (data part)

supposing that the torque boost is large,

When [

Pr. 20 = 60Hz

], acceleration time/deceleration time

setting is as follows.

Therefore set 2.4s or more for acceleration time, and 0.5s or

more for deceleration time.

N = N1 - N2 = - 0 = 1800[r/min]

120 60

4

JT = 0.008 + 0.038 = 0.046 [kg m2]

JM = 0.008 [kg m2],

JL = 0.038 [kg m2],

TLmax = 9.8 [N m],

TLmin = 5.88 [N m], and the acceleration and deceleration

times are as short as possible.

TM = = 11.67[N m]

1800

9550 2.2

tas = = 2.39[s]

0.046 1800

a = 1.15

9.55 (11.67 1.15 - 9.8)

tds = = 0.49[s]

0.046 1800

9.55 (11.67 1.0 + 5.88)

= 1.0

Acceleration time ([

Pr. 7

]) = 2.39 = 2.39

1800 - 0

1800 - 0

1800

1800

Deceleration time ([

Pr. 7

]) = 0.49 = 0.49

common

Summary of Contents for FR-A700 Series

Page 245: ...279 2 PARAMETER PARAMETER MEMO ...

Page 440: ...474 PARAMETER MEMO ...

Page 522: ...556 SELECTION MEMO ...