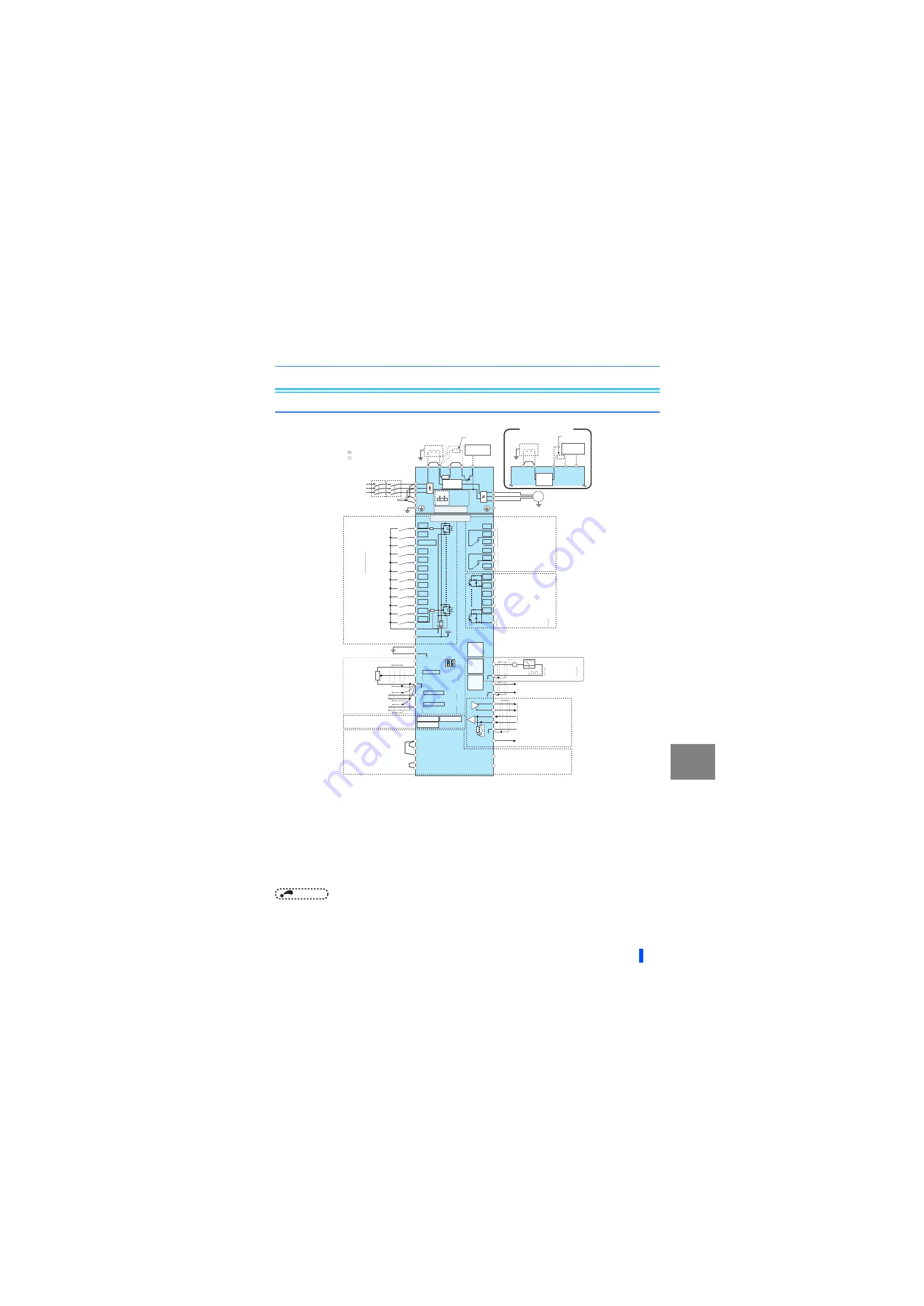

Terminal connection diagrams

7

2

WIRING

2.1

Terminal connection diagrams

For the 75K or higher, always connect a DC reactor (FR-HEL), which is available as an option. (To select a DC reactor, refer to

, and select one according to the

applicable motor capacity.)

When connecting a DC reactor, if a jumper is installed across terminals P1 and P/+, remove the jumper before installing the DC reactor. (The jumper is not installed for

the FR-B-75K or higher.)

When using separate power supply for the control circuit, remove the jumper between R1/L11 and S1/L21.

The function of these terminals can be changed with the input terminal assignment

(Pr.178 to Pr.189)

Terminal JOG is also used as the pulse train input terminal. Use

Pr.291

to choose JOG or pulse.

Terminal input specifications can be changed by analog input specification switchover

(Pr.73, Pr.267)

. To input a voltage, set the voltage/current input switch OFF. To

input a current, set the voltage/current input switch ON. Terminals 10 and 2 are also used as a PTC input terminal.

(Pr.561)

(Refer to the FR-A800 Instruction Manual

(Detailed).)

It is recommended to use 2 W 1 k

Ω

when the frequency setting signal is changed frequently.

If connecting a brake resistor, remove the jumper between PR and PX (FR-B-750 to 7.5K, FR-B3-(N)(H)400 to 7.5K).

Connect a brake resistor across terminals P/+ (P3) and PR. (Terminal PR is equipped in FR-B-750 to 22K (200 V class), FR-B-750 to 55K (400 V class), FR-B3-(N)400

to 22K, FR-B3-(N)H400 to 37K.) Install a thermal relay to prevent overheating and damage of discharging resistors. (Refer to the FR-A800 Instruction Manual

(Detailed).)

The function of these terminals can be changed with the output terminal assignment

(Pr.195, Pr.196)

. (Refer to

The function of these terminals can be changed with the output terminal assignment

(Pr.190 to Pr.194)

. (Refer to

.)

The terminal F/C (FM) can be used to output pulse trains as open collector output by setting

Pr.291

.

Not required when calibrating the scale with the operation panel.

Do not remove the shorting wires across the terminals S1 and PC, the terminals S2 and PC, and the terminals SIC and SD. Removing any shorting wire disables the

inverter operation.

NOTE

• It is mandatory to use the Mitsubishi Electric pressure-resistant, explosion-proof motor with the inverter which has been approved for combination by the Japanese

Ministry of Health, Labor and Welfare's explosion-proof certification. Therefore, always use the Mitsubishi Electric pressure-resistant, explosion-proof motor in

combination with its approved driving inverter.

• To prevent a malfunction due to noise, keep the signal cables 10 cm or more away from the power cables. Also, separate the main circuit cables at the input side from

the main circuit cables at the output side.

• After wiring, wire offcuts must not be left in the inverter. Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting

holes in an enclosure etc., take caution not to allow chips and other foreign matter to enter the inverter.

• Set the voltage/current input switch correctly. Incorrect setting may cause a fault, failure or malfunction.

Three-phase

AC power

supply

MCCB

R/L1

S/L2

T/L3

R1/L11

S1/L21

PC

24VDC power supply

(Common for external power supply transistor)

Forward rotation start

Reverse rotation start

Start self-holding selection

Middle speed

High speed

Low speed

Jog operation

Second function selection

Output stop

Reset

Terminal 4 input selection

(Current input selection)

Selection of automatic restart

after instantaneous

power failure

Frequency setting signals (Analog)

10E(+10V)

10(+5V)

2

(Analog common)

2

3

1

Auxiliary

input

Terminal 4 input

(Current input)

1

4

Frequency setting

potentiometer

1/2W1kΩ

∗6

Running

Up to frequency

Instantaneous

power failure

Overload

Frequency detection

Open collector output common

Sink/source

common

F/C

(FM)

SD

Control input signals

(No voltage input allowed)

∗3

Jumper

Explosion-proof motor

Relay output 1

(Fault output)

C1

B1

A1

U

V

W

P1

Indicator

(Frequency meter, etc.)

+

-

(-)

(+)

Analog signal output

(0 to ±10VDC)

Earth

(Ground)

AM

5

DC0 to ±5V selectable

DC0 to ±10V

Multi-speed

selection

Open collector output

∗10

Moving-coil type

1mA full-scale

Contact input common

Calibration

resistor

∗12

Earth

(Ground)

Main circuit terminal

Control circuit terminal

DC0 to 5V

DC0 to 10V selectable

MC

Main circuit

C2

B2

A2

Relay output 2

Relay output

∗9

M

DC0 to 20mA

DC0 to 5V

DC0 to 10V

selectable

DC4 to 20mA

TXD+

Terminating

resistor

TXD-

RXD+

RXD-

GND

(SG)

Data

transmission

GND

RS-485 terminals

PU

connector

USB A

connector

USB

mini B

connector

SINK

SOURCE

∗4

∗5

∗5

∗11

∗5

∗5

Connector for plug-in option connection

STF

STR

STP(STOP)

RH

RM

RL

JOG

RT

MRS

RES

AU

CS

SD

RUN

SU

IPF

OL

FU

SE

Data

reception

(+)

(-)

5

EMC filter

ON/OFF

connecter

ON

OFF

+24

24V external power

supply input

SD

Common terminal

VCC

(+)

(-)

5V

(Permissible load current 100mA)

Sink logic

∗2

Earth (Ground)

R

R

Connector 1 Connector 2

Connector 3

Jumper

Jumper

PX

PR

N/-

P/+

Control circuit

Initial value

Initial value

Initial value

ON

4

2

OFF

Voltage/current

input switch

Brake unit

(Option)

DC reactor

(FR-HEL)

∗1

Brake resistor

(FR-ABR)

∗7∗8

So (SO)

SOC

S1

S2

PC

SD

SIC

For manufacturer

∗13

Shorting

wire

Jumper

P1

Earth

(Ground)

R

P3

PR

N/-

P/+

Brake unit

(Option)

DC reactor

(FR-HEL)

∗1

Brake resistor

∗8

Inrush

current

limit circuit

FR-B-15K, 22K (200 V class

)

FR-B-15K to 55K (400 V class

)

FR-B3-(N)15K, 22K

FR-B3-(N)H15K to 37K

24V

Inrush current

limit circuit