95

Selection and protection of a motor

4.8 Selection and protection of a motor

4.8.1

Motor overheat protection (Electronic thermal O/L relay, PTC thermistor protection)

(Pr. 9, Pr. 51, Pr. 561)

∗1

The above parameters can be set when

Pr. 160 Extended function display selection

= "0".

∗2

When parameter is read using the FR-PU04, a parameter name different from an actual parameter is displayed.

(1) Electronic thermal O/L relay

(Pr. 9)

Purpose

Parameter that should be Set

Refer to Page

Motor protection from overheat

Electronic thermal O/L relay

PTC thermistor protection

Pr. 9, Pr. 51, Pr. 561

Use the constant torque motor

Applied motor

Pr. 71

The motor performance can be

maximized for operation in magnetic

flux vector control method.

Offline auto tuning

Pr. 71, Pr. 80, Pr. 82 to Pr.

84, Pr. 90, Pr. 96

Set the current of the electronic thermal relay function to protect the motor from overheat. This feature provides the

optimum protective characteristics, including reduced motor cooling capability, at low speed.

Parameter

Number

Name

Initial Value

Setting Range

Description

9

Electronic thermal O/L

relay

Inverter

rated current

0 to 500A

Set the rated motor current.

51

Second electronic thermal

O/L relay

9999

0 to 500A

Valid when the RT signal is on.

Set the rated motor current.

9999

Second electronic thermal O/L relay invalid

561

PTC thermistor protection

level

9999

0.50 to 30k

Ω

Set the level (resistance value) when PTC

thermistor protection activates.

9999

PTC thermistor protection is inactive.

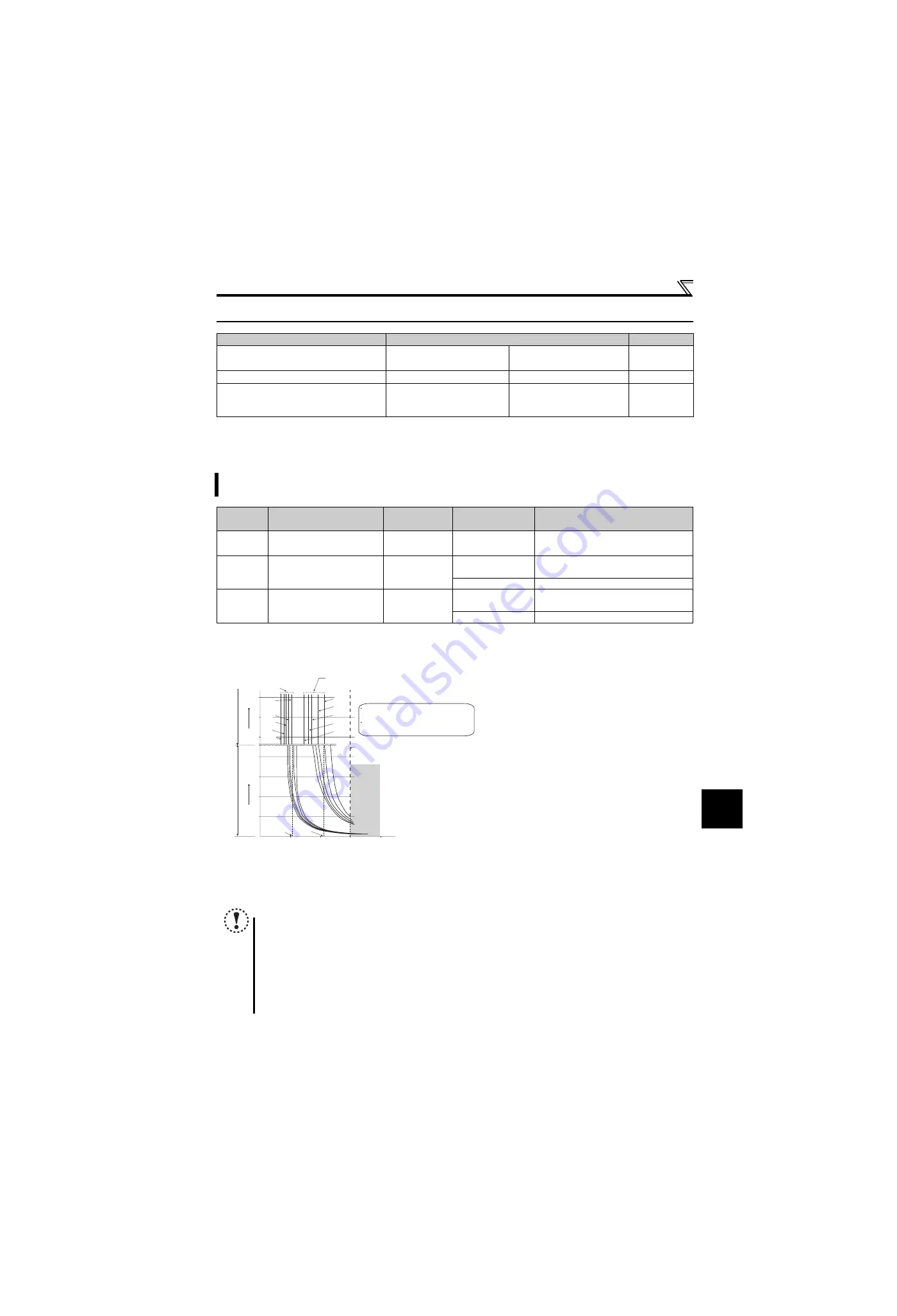

Electronic thermal O/L relay operation characteristic

This function detects the overload (overheat) of the

motor and trips. (The operation characteristic is shown

on the left)

Set the rated current (A) of the motor in

Pr. 9

.

(If the motor has both 50Hz and 60Hz rating and the

Pr. 3 Base frequency

is set to 60Hz, set the 1.1 times of

the 60Hz rated motor current.)

Set "0" in

Pr. 9

when you do not want to operate the

electronic thermal O/L relay, e.g. when using an external

thermal relay with the motor. (Note that the output

transistor protection of the inverter functions (E.THT).)

When using a Mitsubishi constant-torque motor

1)

Set "1" or "13", "50", "53" in any of

Pr. 71

. (This

provides a 100% continuous torque

characteristic in the low-speed range.

2)

Set the rated current of the motor in

Pr. 9

.

∗1

When a value 50% of the inverter rated output current (current value) is set to

Pr. 9

∗2

The % value denotes the percentage to the inverter rated output current. It is not the percentage to the motor rated current.

∗3

When you set the electronic thermal O/L relay dedicated to the Mitsubishi constant-torque motor, this characteristic curve applies to operation at 6Hz or

higher.

NOTE

Fault by electronic thermal relay function is reset by inverter power reset and reset signal input. Avoid unnecessary

reset and power-off.

When multiple motors are operated by a single inverter, protection cannot be provided by the electronic thermal

function. Install an external thermal relay to each motor.

When the difference between the inverter and motor capacities is large and the setting is small, the protective

characteristics of the electronic thermal relay function will be deteriorated. In this case, use an external thermal relay.

A special motor cannot be protected by the electronic thermal relay function.

The operation time of the transistor protection thermal shortens when the

Pr. 72 PWM frequency selection

setting

increases.

Operation range

Range on the right of characteristic curve

Non-operation range

Range on the left of characteristic curve

Range for

transistor

protection

Inverter output current(%)

(% to the rated inverter current)

52.5%

105%

50

100

150

60

120

180

240

50

60

70

(min) unit display in this range

Operation time (min)

Pr. 9

= 50% setting of inverter rating*1, 2

Pr. 9

= 100% setting of inverter rating*2

(s) unit display in this range

Operation time (s)

Characteristic when electronic thermal

relay function for motor protection is turned off

(when

Pr. 9

setting is 0(A))

6Hz

20Hz

10Hz

6Hz

0.5Hz

30Hz or more

*3

30Hz

or more

*3

20Hz

10Hz

0.5Hz

200

Summary of Contents for FR-D700 Series

Page 11: ...VII MEMO ...

Page 23: ...12 MEMO ...

Page 57: ...46 MEMO ...

Page 262: ...258 MEMO ...

Page 276: ...272 MEMO ...

Page 287: ...283 MEMO ...

Page 289: ......