21

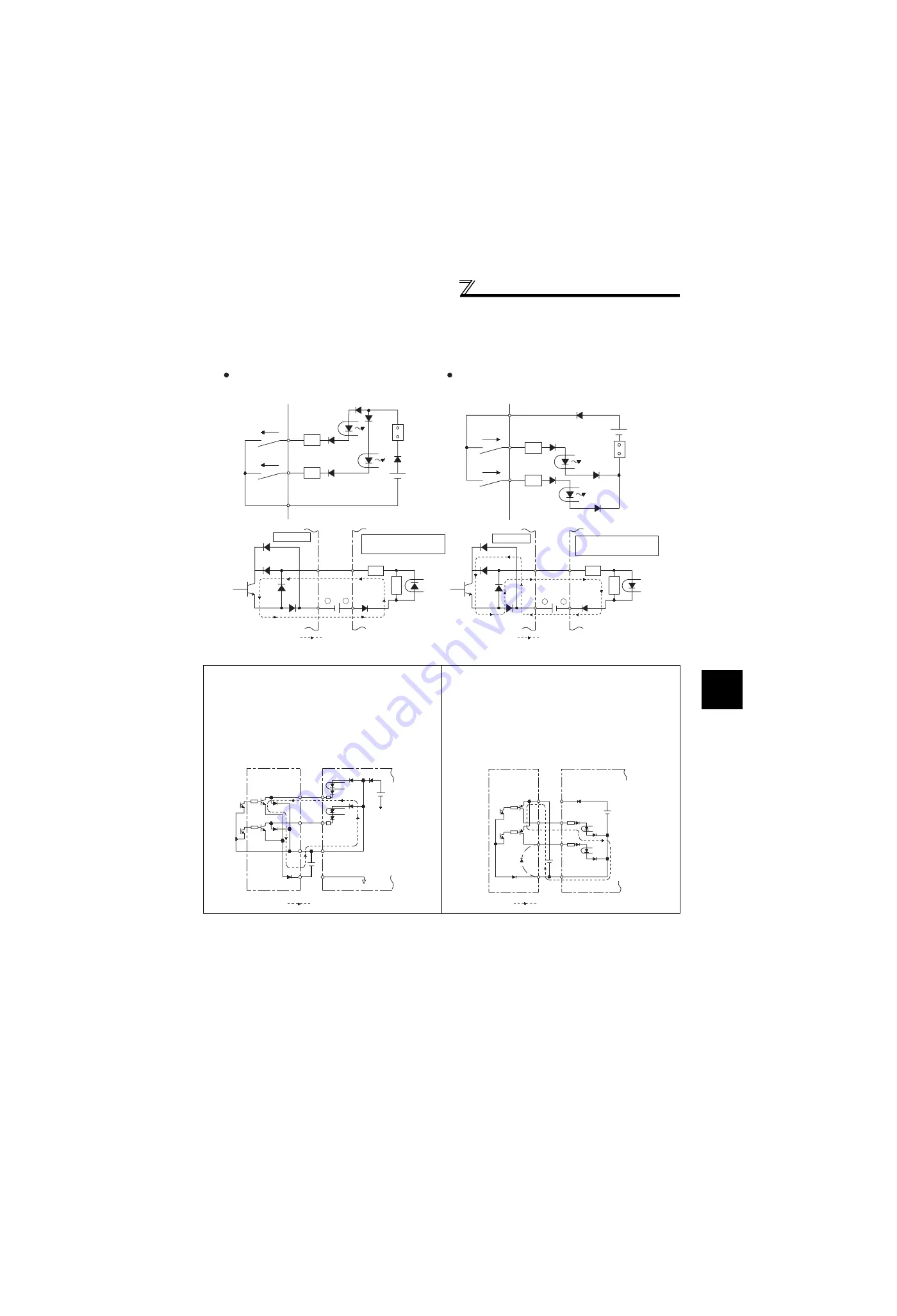

Sink logic and source logic

⋅

In sink logic, a signal switches on when a current flows from the corresponding signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the open collector output signals.

⋅

In source logic, a signal switches on when a current flows into the corresponding signal input terminal.

Terminal PC is common to the contact input signals. Terminal SE is common to the open collector output signals.

•

When using an external power supply for transistor output

⋅

Sink logic type

Use terminal PC as a common terminal to prevent a

malfunction caused by undesirable current. (Do not

connect terminal SD of the inverter with terminal 0V of

the external power supply. When using terminals PC-

SD as a 24VDC power supply, do not install a power

supply in parallel in the outside of the inverter. Doing so

may cause a malfunction due to undesirable current.)

⋅

Source logic type

When using an external power supply for transistor

output, use terminal SD as a common to prevent

misoperation caused by undesirable current.

Current

PC

STF

R

STR

R

Source logic

Source

connector

Current

SD

STF

R

STR

R

Sink

connector

Sink logic

Current flow concerning the input/output signal

when sink logic is selected

Current flow concerning the input/output signal

when source logic is selected

DC input (source type)

<Example: AX80>

24VDC

RUN

SE

1

9

R

Inverter

R

Current flow

+

-

+

-

DC input (sink type)

<Example: AX40>

Inverter

24VDC

RUN

SE

1

9

R

R

Current flow

AY40 type

transistor

output unit

1

2

9

10

24VDC SD

PC

STR

STF

Inverter

24VDC

(SD)

9

Current flow

AY80 type

transistor

output unit

9

1

2

10

PC

STF

STR

SD

Inverter

24VDC

(SD)

24VDC

Current flow

Summary of Contents for FR-F 700 EC

Page 2: ......

Page 142: ...MEMO ...