190

(2) Low Voltage Directive

We have self-confirmed our converters as products compliant to the Low Voltage Directive (Conforming standard EN

61800-5-1) and affix the CE marking on the converters.

Outline of instructions

Do not use an earth leakage circuit breaker as an electric shock protector without connecting the equipment to the earth.

Connect the equipment to the earth securely.

Wire the earth (ground) terminal independently. (Do not connect two or more cables to one terminal.)

Use the cable sizes on

page 31, 48

under the following conditions.

Surrounding air temperature: 40°C maximum

If conditions are different from above, select appropriate wire according to EN60204 ANNEX C TABLE 5.

Use a tinned (plating should not include zinc) crimping terminal to connect the earth cable. When tightening the screw,

be careful not to damage the threads.

For use as a product compliant with the Low Voltage Directive, use PVC cable on

Use the moulded case circuit breaker and magnetic contactor which conform to the EN or IEC Standard.

When using an earth leakage circuit breaker, use a residual current operated protective device (RCD) of type B (breaker

which can detect both AC and DC). If not, provide double or reinforced insulation between the converter and other

equipment, or put a transformer between the main power supply and converter.

Use the inverter under the conditions of overvoltage category II (usable regardless of the earth (ground) condition of the

power supply), overvoltage category III (usable with the earthed-neutral system power supply, 400V class only) specified

in IEC664.

Mount the converter (including all peripheral devices such as outside box, reactor 1, and reactor 2) to the enclosure

panel of IP54 or higher.

On the input and output of the converter, use cables of the type and size set forth in EN60204 Appendix C.

The operating capacity of the relay outputs (terminal symbols A, B, C) should be 30VDC, 0.3A. (Relay output has basic

isolation from the inverter internal circuit.)

Control circuit terminals on

page 34, 47

are safely isolated from the main circuit.

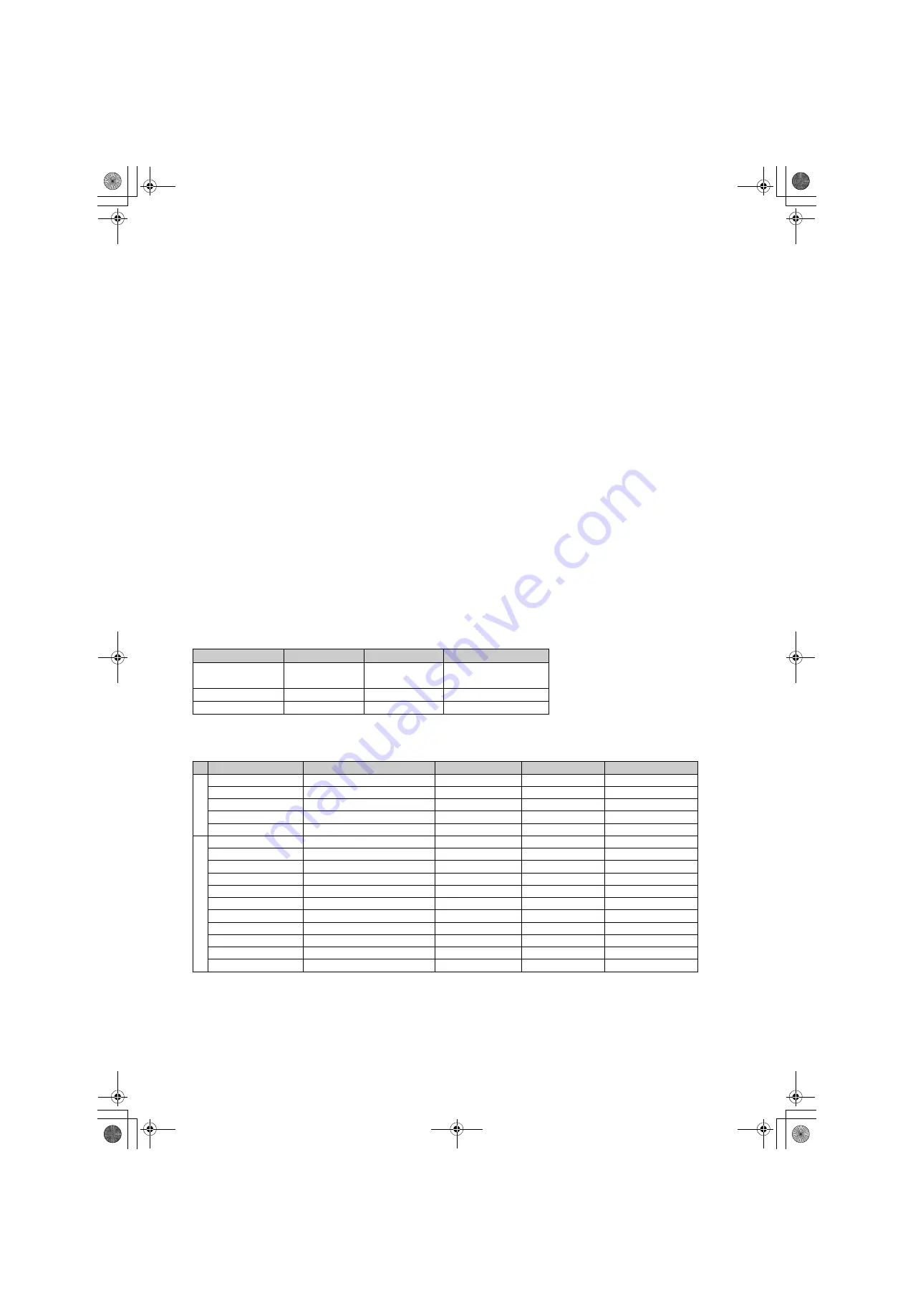

Environment

Provide the Class T fuse or a fuse with faster shutoff speed, which is UL and cUL listed, for branch circuit protection.

Running

In Storage

During Transportation

Surrounding air

temperature

-10°C to +50°C

-20°C to +65°C

-20°C to +65°C

Humidity

90% RH or less

90% RH or less

90% RH or less

Maximum Altitude

1000m

1000m

10000m

Details are given in the technical information "Low Voltage Directive Conformance Guide" (BCN-A21041-203). Please contact your sales

representative.

Converter model

Fuse type

Cat. No

Manufacturer

Rating

2

00V

c

lass

FR-HC2-7.5K

UL Recognized High Speed

170M1414

Bussmann

50A, 700 Vac

FR-HC2-15K

UL Recognized High Speed

170M1416

Bussmann

80A, 700 Vac

FR-HC2-30K

UL Recognized High Speed

170M2666

Bussmann

160A, 700 Vac

FR-HC2-55K

UL Recognized High Speed

170M2669

Bussmann

315A, 700 Vac

FR-HC2-75K

UL Recognized High Speed

170M2671

Bussmann

400A, 700 Vac

40

0V cl

a

ss

FR-HC2-H7.5K

UL Recognized High Speed

170M1411

Bussmann

25A, 700 Vac

FR-HC2-H15K

UL Recognized High Speed

170M1414

Bussmann

50A, 700 Vac

FR-HC2-H30K

UL Recognized High Speed

170M1416

Bussmann

80A, 700 Vac

FR-HC2-H55K

UL Recognized High Speed

170M2666

Bussmann

160A, 700 Vac

FR-HC2-H75K

UL Recognized High Speed

170M2667

Bussmann

200A, 700 Vac

FR-HC2-H110K

UL Recognized High Speed

170M2669

Bussmann

315A, 700 Vac

FR-HC2-H160K

UL Recognized High Speed

170M2671

Bussmann

400A, 700 Vac

FR-HC2-H220K

UL Recognized High Speed

170M3122

Bussmann

550A, 700 Vac

FR-HC2-H280K

UL Recognized High Speed

170M4117

Bussmann

700A, 700 Vac

FR-HC2-H400K

UL Recognized High Speed

170M5116

Bussmann

1000A, 700 Vac

FR-HC2-H560K

UL Recognized High Speed

170M6117

Bussmann

1400A, 700 Vac

HC2.book 190 ページ 2012年11月19日 月曜日 午前10時52分