3 - 16

3.3 CC-Link System Access Range for Monitoring

(3) Setting NW No. and station number

(a)

When monitoring devices RX, RY, RWw and RWr that are allocated to the master station by CC-Link

parameter setting

NW No.: 0, PLC station number: Local

(b)

When monitoring PLC CPU devices of another station

NW No. 0, PLC station number: Other (Station number: n)

(n: Station number of another station to be monitored (0: Master station, 1-64: Local station))

POINT

POINT

POINT

For monitoring devices RX, RY, RWw and RWr that are allocated by CC-Link parameter, use the

local device even if designating devices allocated to another station.

Otherwise, the display speed will be reduced.

■3.

When using CC-Link connection (via G4) (Q series only)

(1) Access range

GT27 can monitor the master station and local stations.

(2) Setting NW No. and station number

(a)

When monitoring master station

NW No.: 0, PLC station number: Host/other (station number: 0)

(b)

When monitoring local station

NW No.: 0, PLC station number: Other (station number: 1 to 64)

(3) Setting device name and device number

Set the device name and device No.

➠

2.DEVICE RANGE THAT CAN BE SET

■4.

Monitoring overview

The following two methods are available for monitoring by the GOT with CC-Link communication unit.

*1

This program is not required if the CC-Link parameter setting sequence program and GOT communication sequence program

satisfy the following conditions.

• Use a QCPU (Q mode) or QnACPU whose number given in the DATE field of the rating plate is "9707B" or later as the PLC

CPU of the master station.

• Use GX Developer or SW2 -GPPW and make CC-Link parameter setting and batch refresh device setting in the CC-Link

setting on the package.

For details of the connection method, refer to the following manual .

➠

User's manual of the CC-Link master unit to be connected

*2

For whether the data can be sent to/received from the CC-Link Ver. 2 compatible station by transient transmission and cyclic

transmission, refer to the following.

➠ ■2.

When using CC-Link connection (intelligent device station)

POINT

POINT

POINT

In transient transmission, connection of several (five or more as a guideline) intelligent device

stations (GOTs and intelligent device units) reduces the data communication speed.

To raise the data communication speed, increase the CC-Link system, for example, and do not

connect five or more intelligent device stations to a single CC-Link system.

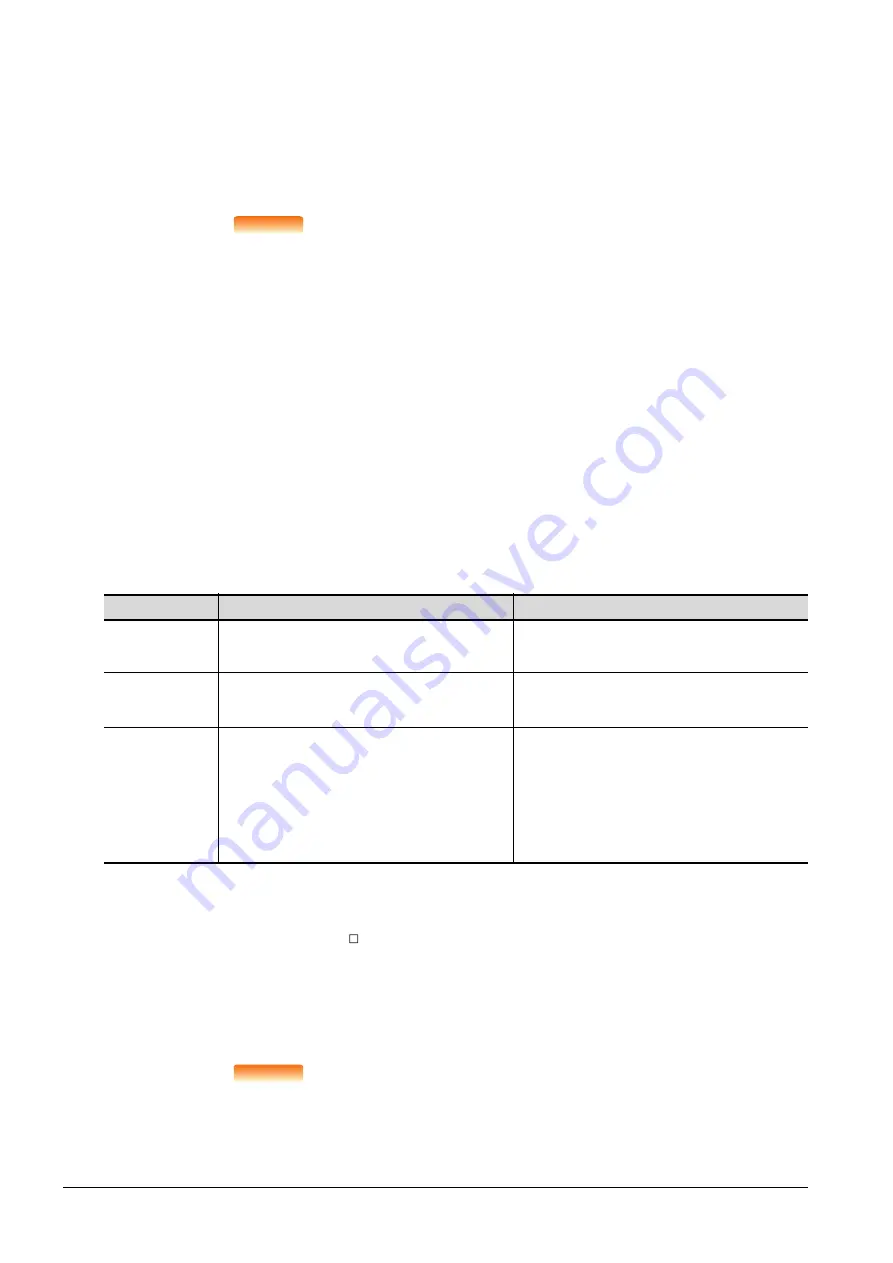

Monitoring method

Monitoring by transient transmission

*2

Monitoring by cyclic transmission

*2

Contents

Devices of the PLC CPU on the CC-Link system master and

local station are specified and monitored.

All remote inputs/outputs and remote registers assigned to

the Master station by CC-Link parameter setting are specified

and monitored.

Advantage

The CC-Link parameter setting sequence program is

required. However, the GOT communication sequence

program is not needed.

*1

The data communication processing speed is high.

Disadvantage

The data communication processing speed is lower than that

of cyclic transmission.

• Writing from the GOT (read command from the

master station) can be performed only to remote

outputs and remote registers assigned to the GOT

of the master station and to the GOT internal

registers.

• GOT communication sequence program is

required.

*1

Summary of Contents for GOT2000 Series

Page 2: ......

Page 84: ......

Page 432: ...6 58 6 6 Precautions ...

Page 578: ...9 54 9 6 Precautions ...

Page 726: ...12 84 12 5 Precautions ...

Page 756: ......

Page 822: ...14 66 14 4 Device Range that Can Be Set ...

Page 918: ...15 96 15 7 Precautions ...

Page 930: ...16 12 16 6 Precautions ...

Page 964: ......

Page 1002: ...19 38 19 7 Precautions ...

Page 1022: ...20 20 20 5 Precautions ...

Page 1023: ...MULTI CHANNEL FUNCTION 21 MULTI CHANNEL FUNCTION 21 1 ...

Page 1024: ......

Page 1054: ...21 30 21 5 Multi channel Function Check Sheet ...

Page 1055: ...FA TRANSPARENT FUNCTION 22 FA TRANSPARENT FUNCTION 22 1 ...

Page 1056: ......

Page 1223: ......