4.2 MELSEC Q Series

4 - 59

4

HOW T

O

MONIT

O

R REDUNT

ANT SYSTEM

■3.

Precautions when connecting a GOT directly to a PLC CPU in the redundant system

without making MELSEC redundant setting

• As the GOT monitors exclusively the PLC CPU that is directly connected to, the monitor target cannot be changed in

response to the system switching of the redundant system.

To change the target monitor in response to the system switching, change the target of the connection cable between

the GOT and PLC CPU to the other PLC CPU, or configure the system using GOTs connected to each PLC CPU.

• In CPU direct connection, when monitoring a PLC CPU in the redundant system, only the PLC CPU that is directly

connected to the GOT can be monitored.

• When connected to the standby system PLC CPU, the writing of the GOT to a device in the connected PLC CPU is

not reflected. Design a monitor screen that disables writing to the standby system.

In the redundant system, the tracking function transfers device data from control system to standby system.

When the tracking function is enabled, the device value of the standby system PLC CPU is overwritten by the device

value transferred from the control system to the standby system even if the GOT writes to the standby system PLC

CPU (Numerical input, Ascii input, Script, Recipe, or others).

As countermeasures to the above, perform the following.

• Display a monitor screen which indicates that "the connected PLC CPU is the standby system" on a GOT when

connecting the GOT to the standby system PLC CPU.

• To display the specified monitor screen when connecting the GOT to the standby system PLC CPU, use the special

relay SM1515 (Control status identification flag) of the PLC CPU.

(When the SM1515 is OFF, the connected PLC CPU is the standby system)

• Control the operation of each object by the SM1515, which is set for the operation condition.

• For the screen switching device, use a GOT internal device.

If a device of the PLC CPU is used, the trigger action operation of the GOT may be disabled since the device data of

the PLC CPU will is overwritten by the device value transferred with the redundant system tracking function.

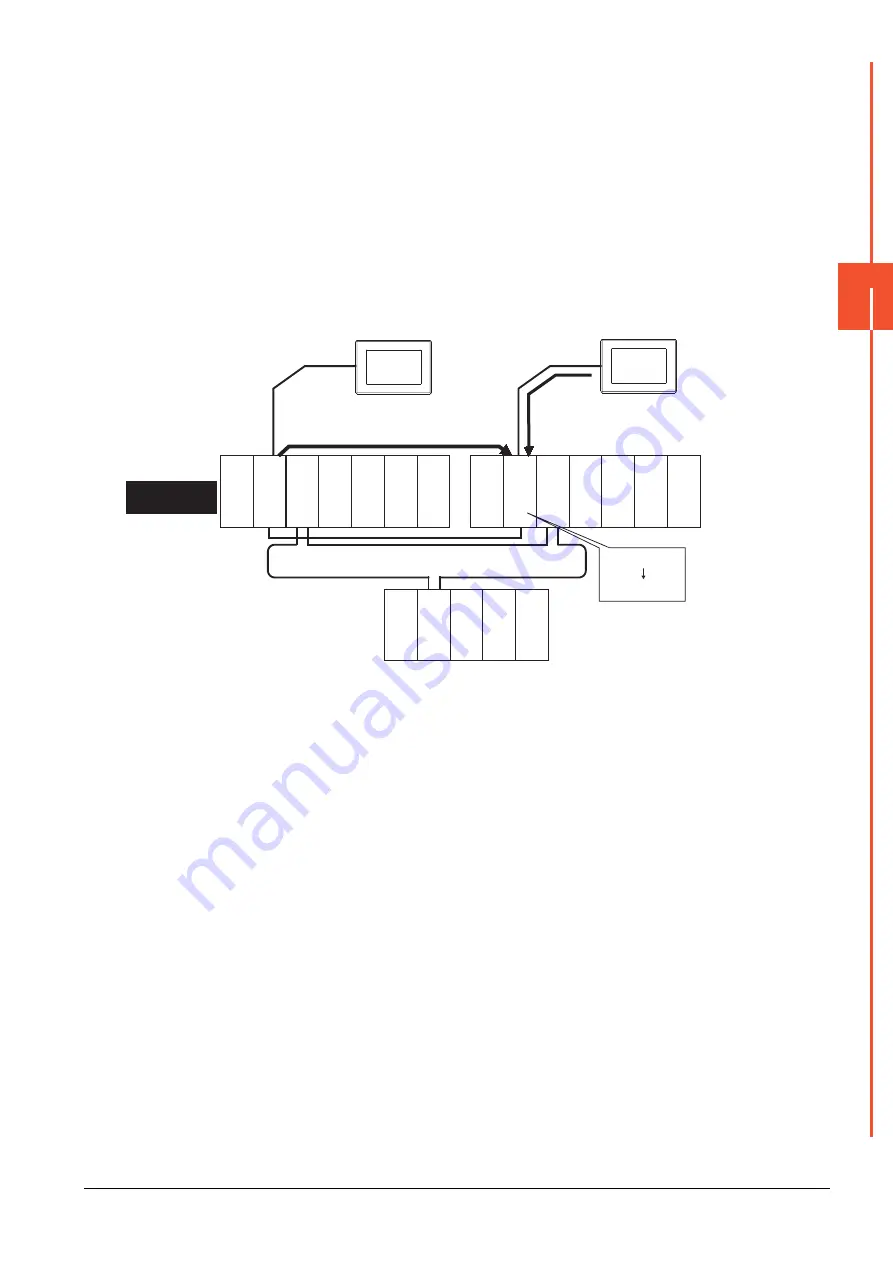

1) Numerically input D100=100

from the GOT.

1) D100=100

2) D100=5

2) Tracks D100=5 from control

system to standby system.

Power supply

module

Power supply

module

Power supply

module

MELSECNET/H remote I/O network

CPU direct connection

CPU direct connection

GOT1

Control system

(System A)

Empty

Empty

Empty

Empty

Q25PRHCPU

QJ71LP21-25

QJ71BR1

1

QJ71E71-100

QJ61BT1

1N

Standby system

(System B)

QJ72LP25-25

QJ71C24N

Q25PRHCPU

QJ71LP21-25

QJ71BR1

1

QJ71E71-100

QJ61BT1

1N

GOT2

Summary of Contents for GOT2000 Series

Page 2: ......

Page 84: ......

Page 432: ...6 58 6 6 Precautions ...

Page 578: ...9 54 9 6 Precautions ...

Page 726: ...12 84 12 5 Precautions ...

Page 756: ......

Page 822: ...14 66 14 4 Device Range that Can Be Set ...

Page 918: ...15 96 15 7 Precautions ...

Page 930: ...16 12 16 6 Precautions ...

Page 964: ......

Page 1002: ...19 38 19 7 Precautions ...

Page 1022: ...20 20 20 5 Precautions ...

Page 1023: ...MULTI CHANNEL FUNCTION 21 MULTI CHANNEL FUNCTION 21 1 ...

Page 1024: ......

Page 1054: ...21 30 21 5 Multi channel Function Check Sheet ...

Page 1055: ...FA TRANSPARENT FUNCTION 22 FA TRANSPARENT FUNCTION 22 1 ...

Page 1056: ......

Page 1223: ......