49 - 8

49. CONNECTION TO YASKAWA PLC

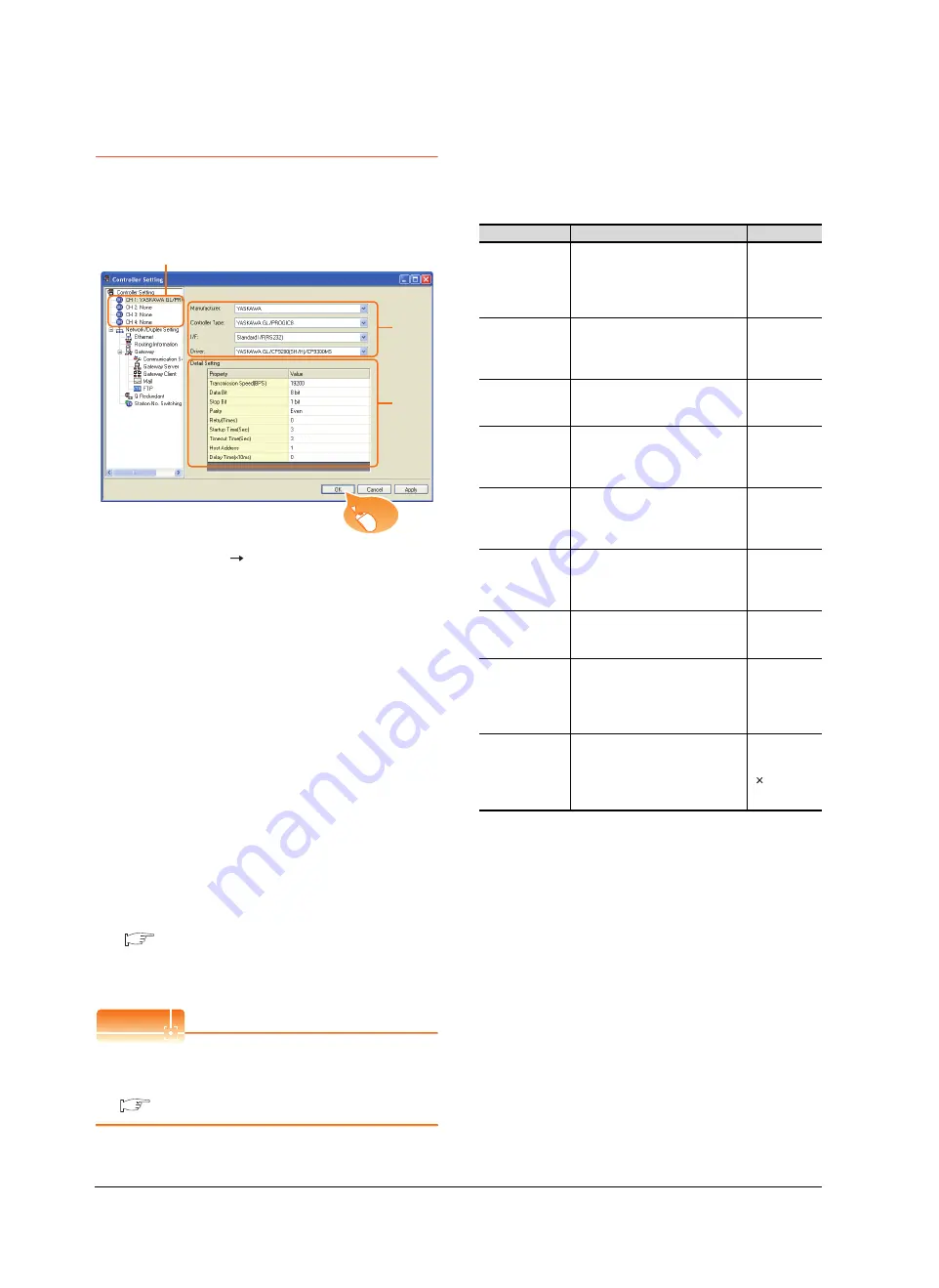

49.2 Serial Connection

49.2.8 GOT Side Settings

Setting communication interface

(Communication settings)

Set the channel of the connected equipment.

1.

Select [Common]

[Controller Setting] from the

menu.

2.

The Controller Setting window is displayed. Select the

channel to be used from the list menu.

3.

Set the following items.

• Manufacturer: YASKAWA

• Controller Type: Set either of the followings.

drdotGL/PROGIC8

• CP9200SH/MP900 series

• CP9200(H)

• CP9300MS (MC compatible)

• MP2000/MP900

• MP2000/MP900/CP9200SH series

• I/F: Interface to be used

• Driver: Set either of the following.

• YASKAWA GL/CP9200(SH/H)/CP9300MS

The detailed setting is displayed after Manufacturer,

Controller Type, I/F, and Driver are set.

Make the settings according to the usage

environment.

■

Click the [OK] button when settings are completed.

POINT

POINT

POINT

The settings of connecting equipment can be

confirmed in [I/F Communication Setting].

For details, refer to the following.

17.1.2 I/F communication setting

Communication detail settings

Make the settings according to the usage environment.

(1) YASKAWA GL/CP9200(SH/H)/CP9300MS

2.

3.

4.

Click!

Item

Description

Range

Transmission

Speed

Set this item when change the

transmission speed used for

communication with the connected

equipment.

(Default: 19200bps)

4800bps,

9600bps,

19200bps,

38400bps,

57600bps

Data Bit

Set this item when change the data

length used for communication with

the connected equipment.

(Default: 8bit)

8bit (fixed)

Stop Bit

Specify the stop bit length for

communications.

(Default: 1bit)

1bit (fixed)

Parity

Specify whether or not to perform a

parity check, and how it is performed

during communication.

(Default: Even)

Even (fixed)

Retry

Set the number of retries to be

performed when a communication

error occurs.

(Default: 0time)

0 to 5times

Startup Time

Specify the time period from the GOT

startup until GOT starts the

communication with the PLC CPU.

(Default: 3sec)

3 to 30sec

Timeout Time

Set the time period for a

communication to time out.

(Default: 3sec)

3 to 30sec

Host Address

Specify the host address (station No.

of the PLC to which the GOT is

connected) in the network of the

GOT.

(Default: 1)

1 to 31

Delay Time

Set this item to adjust the

transmission timing of the

communication request from the

GOT.

(Default: 0ms)

0 to 30

(

10 ms)

Summary of Contents for GT16

Page 1: ......

Page 2: ......

Page 46: ...1 4 1 OVERVIEW 1 1 Features ...

Page 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Page 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Page 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Page 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Page 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Page 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Page 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Page 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Page 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Page 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Page 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Page 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Page 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Page 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Page 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Page 422: ...REVISIONS 4 ...

Page 425: ......

Page 426: ......

Page 427: ......

Page 428: ......

Page 470: ......

Page 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Page 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Page 584: ......

Page 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Page 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Page 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Page 648: ......

Page 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Page 660: ......

Page 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Page 676: ......

Page 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Page 744: ......

Page 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Page 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Page 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Page 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Page 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Page 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Page 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Page 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Page 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Page 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Page 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Page 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Page 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Page 1132: ......

Page 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Page 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Page 1272: ......

Page 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Page 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Page 1294: ......

Page 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Page 1302: ...REVISIONS 4 ...

Page 1305: ......

Page 1306: ......