- 1 -

FOR YOUR SAFETY!

If you operate this attachment first time, please make sure to read the following instructions for

your safety and proper operation.

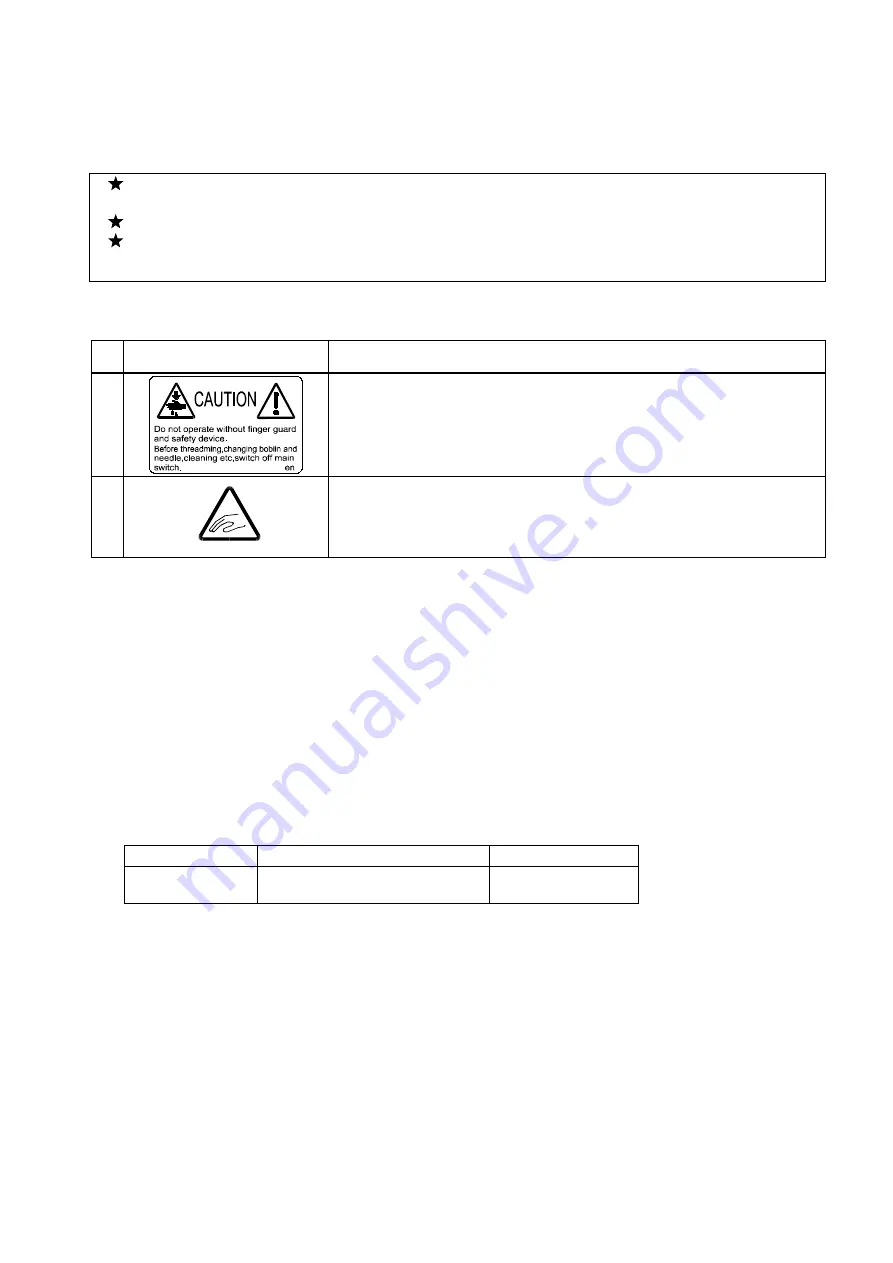

Explanations for the warning signs

No

Warning sign

Meanings of warning sign

1

Caution for sewing machine operation

:

Warning to operate the sewing machine without safety

guards and to prohibit doing any operation except sewing

while the power is turned ON.

2

Caution for the fingers to be caught in the machine

:

Warning to a possible danger to be caught the fingers in the

machine under the specified operation.

1. Features

1. This device is designed to effectively shorten the tail lengths after trimming.

2. The LU-ST kit attaches to the machine without any machining.

3. The elimination of additional hand trimming will increase production.

4. Any damage to sewn parts caused by hand trimming will be eliminated.

5. The Mitsubishi genuine knife mechanism provides a reliable and durable trim function.

2. Correspondence model

Type

Correspondence

Control box

LU-ST KIT

LU2-4410-B1T-CS

XC-GMFY

* A sewing machine made in before April 1995 doesn’t correspond to LU-ST KIT.

3. Specification

1. Max. stitch length is limited to 8mm.

2. The air inlet diameter is 8mm.

3. The air regulator and branch device are not enclosed with this kit and must be prepared by the user.

This instruction manual explains the instructions how to operate and maintain the sewing

machine.

All information in this instruction manual are subject to change without notice.

MITSUBISHI ELECTRIC CORPORATION has all the copy rights on this instruction manual.

Reprinting the parts or all of this instruction manual is not allowed without

permission.