H

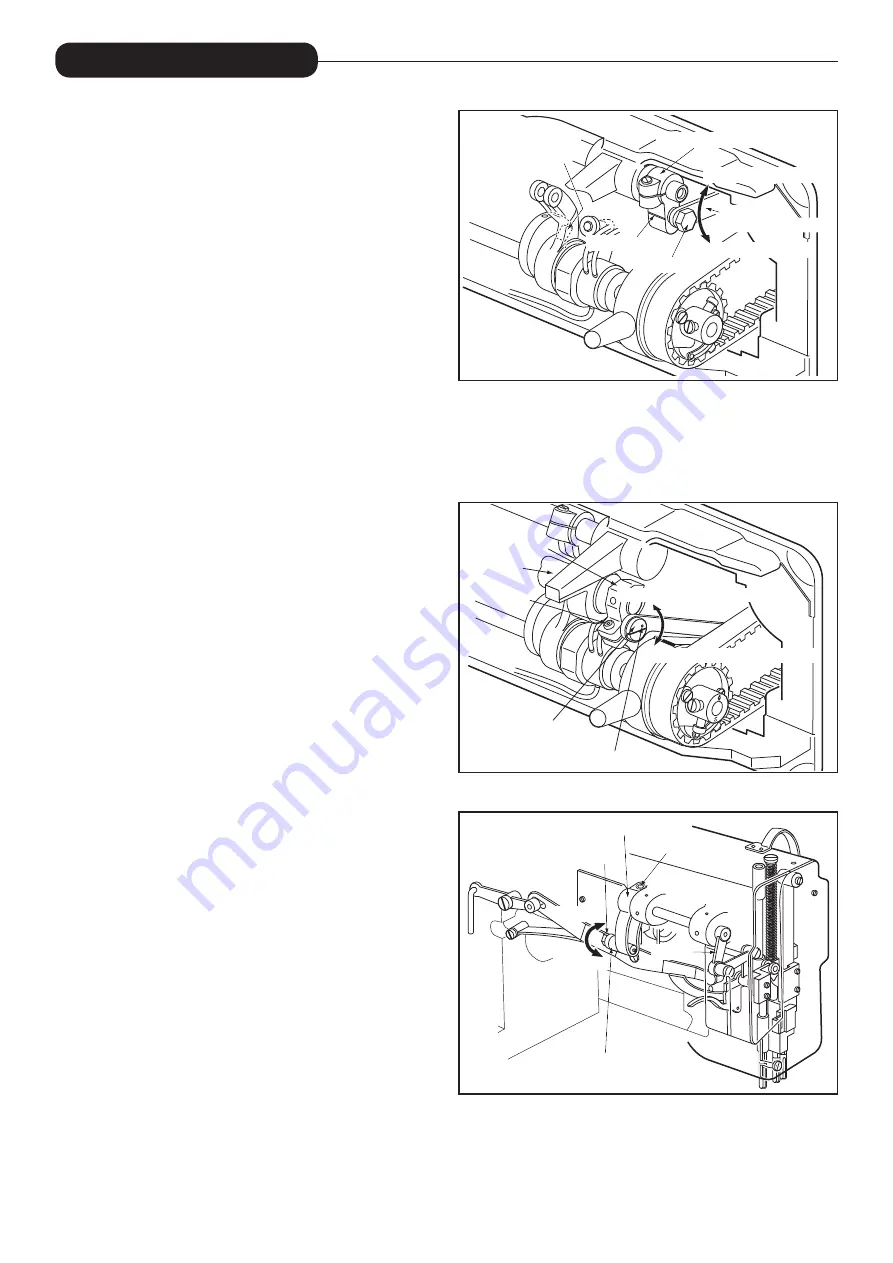

Adjustment of upper feed

length (needle side)

If uneven feeding occurs according to the fabric,

adjust the long hole of the feed rock shaft crank

(right) to adjust the upper feed length.

(How to adjust)

( 1 ) Loosen the special bolt.

( 2 ) Move the special bolt upward to decrease the upper feed.

( 3 ) Move the special bolt downward to increase the upper

feed. (The upper feed and the lower feed theoretically

become equal when the center of the special bolt

matches the reference line of the feed rock shaft crank)

( 4 ) After adjusting, tighten the special bolt.

Note: If the special bolt is overtightened, the link and

the feed rock shaft crank (right) may not work.

I

Adjustment of forward/

backward feed length

The forward/backward feed length can be adjusted

by moving the eccentric pin as shown in the figure.

( 1 ) Loosen the reverse stitch shaft crank screw.

( 2 ) To increase forward stitch length, turn the

eccentric pin clockwise.

To increase backward stitch length, turn the

eccentric pin counterclockwise.

Note: Please adjust in the range where the mark

point of the eccentric pin is facing to the

reverse block side as shown in the figure.

J

Adjustment of the outside presser

foot and the inside presser foot

1 . Adjustment of working height of the outside

presser foot and the inside presser foot.

Please adjust working height of the presser foot

when sewing the fabric having large elasticity

or varying the thickness of the fabric.

(How to adjust)

( 1 ) Loosen the special bolt.

( 2 ) Working height is the biggest when the

crank rod is moved upward and set.

( 3 ) Working height is the smallest when the

crank rod is moved downward and set.

( 4 ) After adjusting, fully tighten the special bolt.

● Working height of the presser foot can be

adjusted in the range from 2mm to 6mm.

HOW TO USE

Push button

engaging part

Feed rock shaft crank (right)

Special bolt

Reference line

Link

(Needle bar rock link)

Upper feed decreases

Upper feed increases

Backward stitch length increases

Reverse stitch

shaft crank

Reverse

block

Eccentric pin

Mark point

Screw

Forward stitch length increases

Special bolt

Crank rod

Screw Ⓐ

Feed lifting rock shaft crank

Arm Ⓑ

Increase

Decrease

— 13 —