6SHFL¿FDWLRQVDUHVXEMHFWWRFKDQJHZLWKRXWQRWLFH

© 2016 Mitsubishi Electric US, Inc.

41

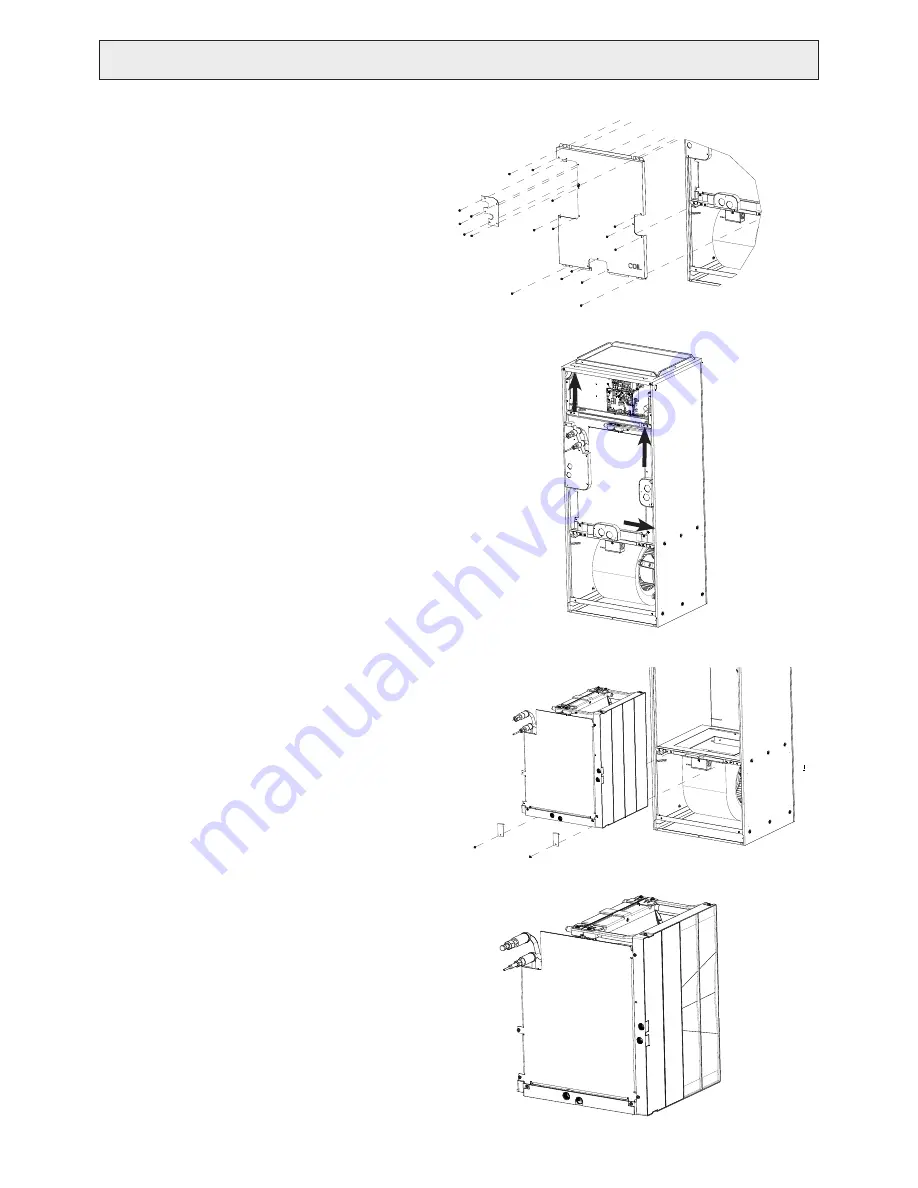

4 Remove the (1 or 2) brackets that secure the

coil, unplug the thermistors from the control

board and route the wires out of the control box

area and into the coil section. Next, slide the

coil from the frame.

1. Remove the Electrical, Blower and Filter panel

indicated in sections 1 and 2.

2. Remove the Coil panel by removing all of the

screws securing it to the (3) smaller panels for

refrigerant and drain lines.

Fig. 6

Fig. 7

Exercise caution when removing heavy parts.

13-3. Coil Assembly

Fig. 5

Fig. 8

3. Slide the smaller panels in the directions indicated

and remove.

Summary of Contents for M-SERIES

Page 2: ......