Appendix

A

−

7

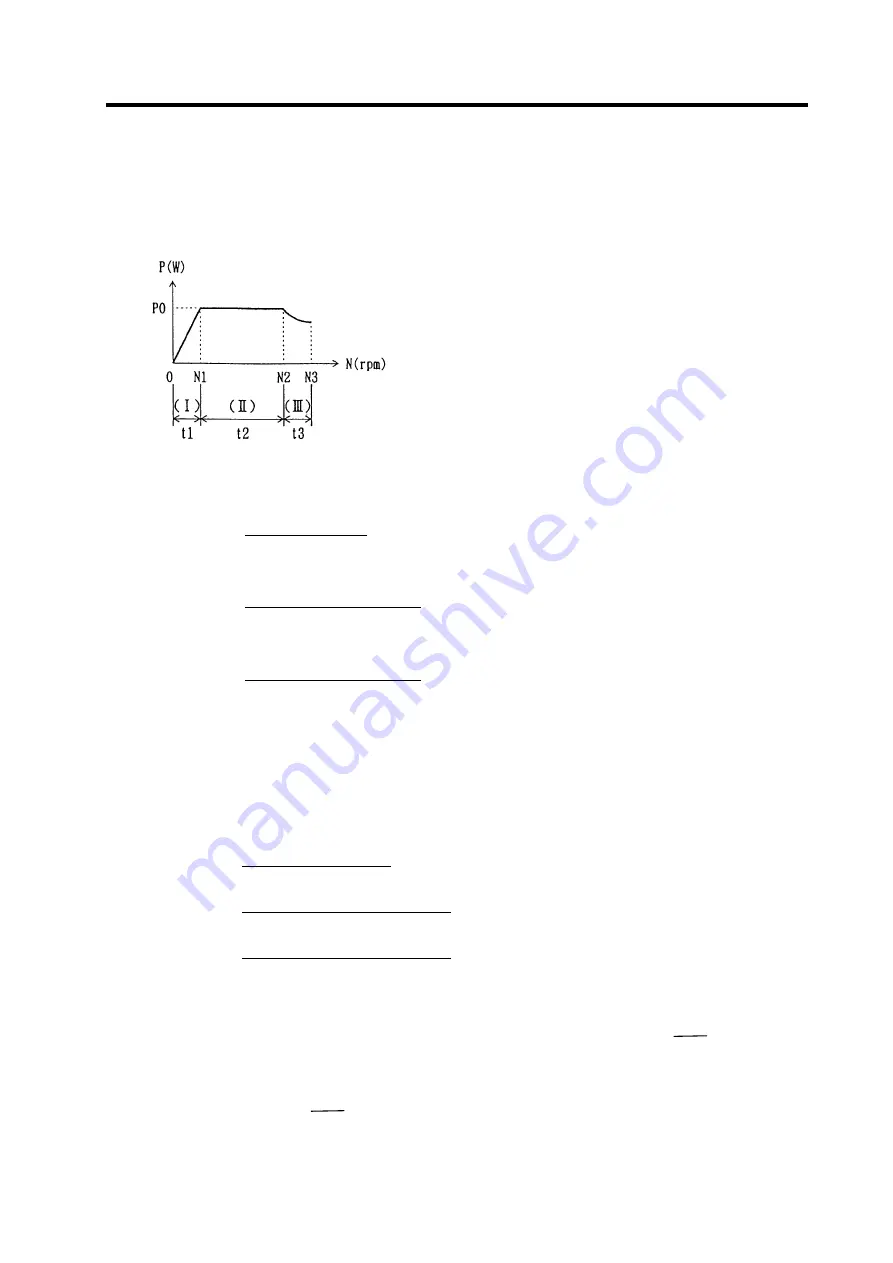

Appendix 3 Theoretical acceleration and deceleration times

In the calculation described below, load torque is assumed to be zero. Therefore, acceleration and

deceleration times determined here somewhat differ from actual acceleration and deceleration times.

(1) Definition

(2) Acceleration/deceleration time "t"

1) Constant torque zone

t1 =

1.03

×

GD

2

×

N1

2

375

×

Po

(sec)

2) Constant output (power) zone

t2 =

1.03

×

GD

2

×

(N2

2

−

N1

2

)

2

×

375

×

Po

(sec)

3) Reduced output zone

t3 =

1.03

×

GD

2

×

(N3

2

−

N2

2

)

2

×

375

×

Po

×

N2

(sec)

Therefore, accel/decel. Time t (0

→

N

3

) is,

t = t

1

+ t

2

+ t

3

(sec)

Example

: GD

2

L

= 0.11kgfm

2

For motor SJ-PF3.7-01

From specification 2, GD

2

M

= 0.034kgm

2

thus, GD

2

= 0.034 + 0.11 = 0.144kgfm

2

t

1

=

1.03

×

0.144

×

1500

2

375

×

3700

×

1.2

= 0.200 (sec)

t

2

=

1.03

×

0.144

×

(6000

2

−

1500

2

)

2

×

375

×

3700

×

1.2

= 1.503 (sec)

t

3

=

1.03

×

0.144

×

(8000

2

−

6000

2

)

3

×

375

×

3700

×

1.2

×

6000

= 1.465 (sec)

Unit conversion

:

Forth : 1kgf = 9.8N

Speed

: 1rpm =

2

π

60

rad/s

Torque : 1kgfm = 9.8Nm = 10

2

kgm

Output (power) : 1kW = 1/1.3596HP

P =

ω

To = (2

π

N

60

)

×

9.8T

(Notes)

1) "Po" is (Rated power

×

1.2).

Example

: For spindle of 2.2/3.7kW,

Po = 3700

×

1.2 = 4440 (W)

2)

GD

2

= (Motor GD

2

) +

(GD

2

converted into load to motor shaft) (kg

•

m

2

)

P :

Output

[w]

ω

: Angular velocity [rad/s]

To : Torque [N

−

m]

N :

Speed

[rpm]

T :

Torque

[kgm]