7 - 9

MDS-D-SVJ3/SPJ3 Series Specifications Manual

7-1 Selection of the servomotor

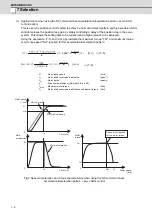

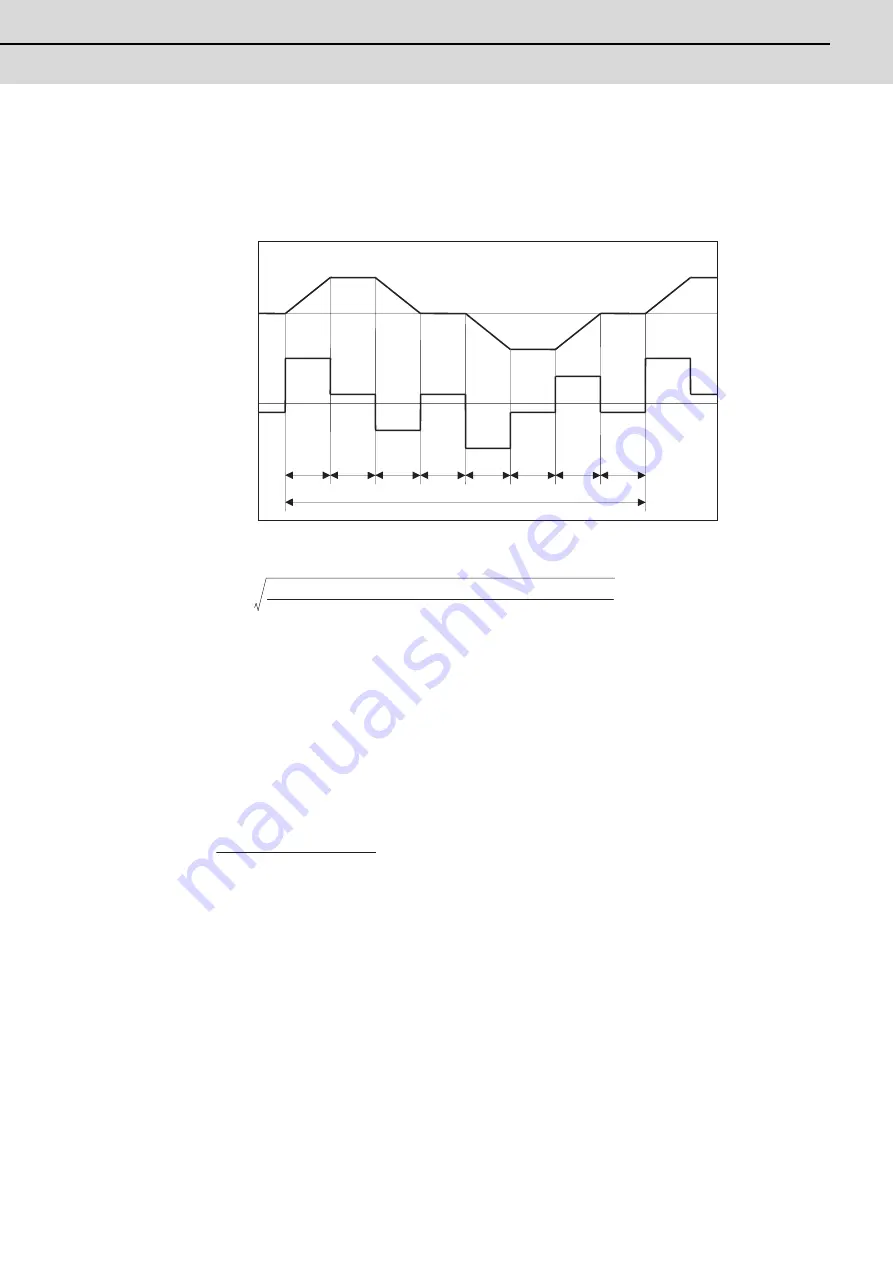

(3) Continuous characteristics

A typical operation pattern is assumed, and the motor's continuous effective load torque (Trms) is calculated

from the motor shaft conversion and load torque. If numbers <1> to <8> in the following drawing were

considered a one cycle operation pattern, the continuous effective load torque is obtained from the root

mean square of the torque during each operation, as shown in the expression (7-9).

Fig. 1 Continuous operation pattern

••• (7-9)

Select a motor so that the continuous effective load torque Trms is 80% or less of the motor stall torque Tst.

Trms

0.8•Tst ••• (7-10)

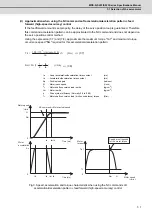

The amount of acceleration torque (Ta) shown in tables 7-3 and 7-4 is the torque to accelerate the load

inertia in a frictionless state. It can be calculated by the expression (7-11). (For linear acceleration/

deceleration)

••• (7-11)

For an unbalance axis, select a motor so that the motor shaft conversion load torque (friction

unbalance torque) is 60% or less of the stall.

TL

0.6•Tst ••• (7-12)

N

: Motor reach speed

(r/min)

J

L

: Motor shaft conversion load inertia

(kg•cm

2

)

J

M

: Motor inertia

(kg•cm

2

)

ta

: Linear acceleration/deceleration time constant

(ms)

η

: Drive system efficiency (Normally 0.8 to 0.95)

0

0

T3

T2

t1 t2 t3 t4

t0

T1

T4

T5

T6

T7

T8

t5 t6 t7 t8

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Motor

torque

Motor

speed

Time

Trms =

T1

2

·t

1+T2

2

·t2

+T3

2

·t3

+T4

2

·t4

+T5

2

·t5

+T6

2

·t6

+T7

2

·t7

+T8

2

·t8

t0

≦

T

a

=

ta

1.05

10

-2

(J

L

/

η

+

J

M

)

N

(N

.

m)

≦

Summary of Contents for MDS-D-SPJ3

Page 1: ......

Page 3: ......

Page 5: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 27: ......

Page 31: ......

Page 39: ...1 8 ...

Page 65: ...2 26 ...

Page 93: ...3 28 ...

Page 169: ...5 58 ...

Page 233: ...Appendix 2 10 ...

Page 257: ...Appendix 4 20 ...

Page 280: ......

Page 284: ......