Outline for MDS-D-SVJ3/SPJ3 Series

Instruction Manual (IB-1500193-D)

1 Installation

1-1 Installation of servomotor

1-1-1 Environmental conditions

1-1-2 Quakeproof level

1-1-3 Cautions for mounting load (prevention of

impact on shaft)

1-1-4 Installation direction

1-1-5 Shaft characteristics

1-1-6 Machine accuracy

1-1-7 Coupling with the load

1-1-8 Oil/water standards

1-1-9 Installation of servomotor

1-1-10 Cable stress

1-2 Installation of spindle motor

1-2-1 Environmental conditions

1-2-2 Shaft characteristics

1-3 Installation of tool spindle motor

1-3-1 Environmental conditions

1-3-2 Shaft characteristics

1-4 Installation of the drive unit

1-4-1 Environmental conditions

1-4-2 Installation direction and clearance

1-4-3 Prevention of entering of foreign matter

1-4-4 Heating value

1-4-5 Heat radiation countermeasures

1-5 Installation of the spindle detector

1-5-1 Spindle side ABZ pulse output detector

(OSE-1024 Series)

1-5-2 Spindle side PLG serial output detector

(TS5690, MU1606 Series)

1-5-3 Installation accuracy diagnosis for PLG

detector

1-6 Noise measures

2 Wiring and Connection

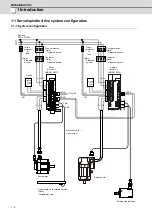

2-1 Part system connection diagram

2-2 Main circuit terminal block/control circuit

connector

2-2-1 Names and applications of main circuit

terminal block signals and control

circuit connectors

2-2-2 Connector pin assignment

2-2-3 Main circuit connector (CNP1,CNP2,CNP3)

wiring method

2-3 NC and drive unit connection

2-4 Connecting with optical communication repeater

unit

2-5 Motor and detector connection

2-5-1 Connection of the servomotor

2-5-2 Connection of the full-closed loop system

2-5-3 Connection of the spindle motor

2-5-4 Connection of the tool spindle motor

2-6 Connection of power supply

2-6-1 Power supply input connection

2-6-2 Connection of the grounding cable

2-7 Connection of regenerative resistor

2-7-1 Standard built-in regenerative resistor (Only

for MDS-D-SVJ3)

2-7-2 External option regenerative resistor

2-8 Wiring of the peripheral control

2-8-1 Wiring of the Input/output circuit

2-8-2 Wiring of the contactor control

2-8-3 Wiring of the motor magnetic brake (MDS-

D-SVJ3)

2-8-4 Wiring of an external emergency stop

2-8-5 Safety observation function

2-8-6 Specifications of proximity switch

3 Setup

3-1 Initial setup

3-1-1 Setting the rotary switch

3-1-2 Setting DIP switch

3-1-3 Transition of LED display after power is

turned ON

3-2 Setting the initial parameters for the servo drive

unit

3-2-1 Setting of servo specification parameters

3-2-2 Setting of machine side detector

3-2-3 List of standard parameters for each

servomotor

3-2-4 Servo parameters

3-3 Setting the initial parameters for the spindle drive

unit

3-3-1 Setting of parameters related to the spindle

3-3-2 List of standard parameters for each spindle

motor

3-3-3 Spindle specification parameters

3-3-4 Spindle parameters

4 Servo Adjustment

4-1 D/A output specifications for servo drive unit

4-1-1 D/A output specifications

4-1-2 Output data settings

4-1-3 Setting the output magnification

4-2 Servo adjustment procedure

4-3 Gain adjustment

4-3-1 Current loop gain

4-3-2 Speed loop gain

4-3-3 Position loop gain

4-4 Characteristics improvement

4-4-1 Optimal adjustment of cycle time

4-4-2 Vibration suppression measures

4-4-3 Improving the cutting surface precision

4-4-4 Improvement of characteristics during

acceleration/deceleration

4-4-5 Improvement of protrusion at quadrant

changeover

4-4-6 Improvement of overshooting

4-4-7 Improvement of the interpolation control

path

4-5 Adjustment during full closed loop control

4-5-1 Outline

Summary of Contents for MDS-D-SPJ3

Page 1: ......

Page 3: ......

Page 5: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 27: ......

Page 31: ......

Page 39: ...1 8 ...

Page 65: ...2 26 ...

Page 93: ...3 28 ...

Page 169: ...5 58 ...

Page 233: ...Appendix 2 10 ...

Page 257: ...Appendix 4 20 ...

Page 280: ......

Page 284: ......