MDS-E/EH Series Instruction Manual

5 Servo Adjustment

314

IB-1501229-F

5.7 Servo Control Signal

The sequence input/output signals exchanged between the NC and servo drive unit are explained in this section. The

status of each signal is displayed on the NC SERVO MONITOR screen.

5.7.1 Servo Control Input (NC to Servo)

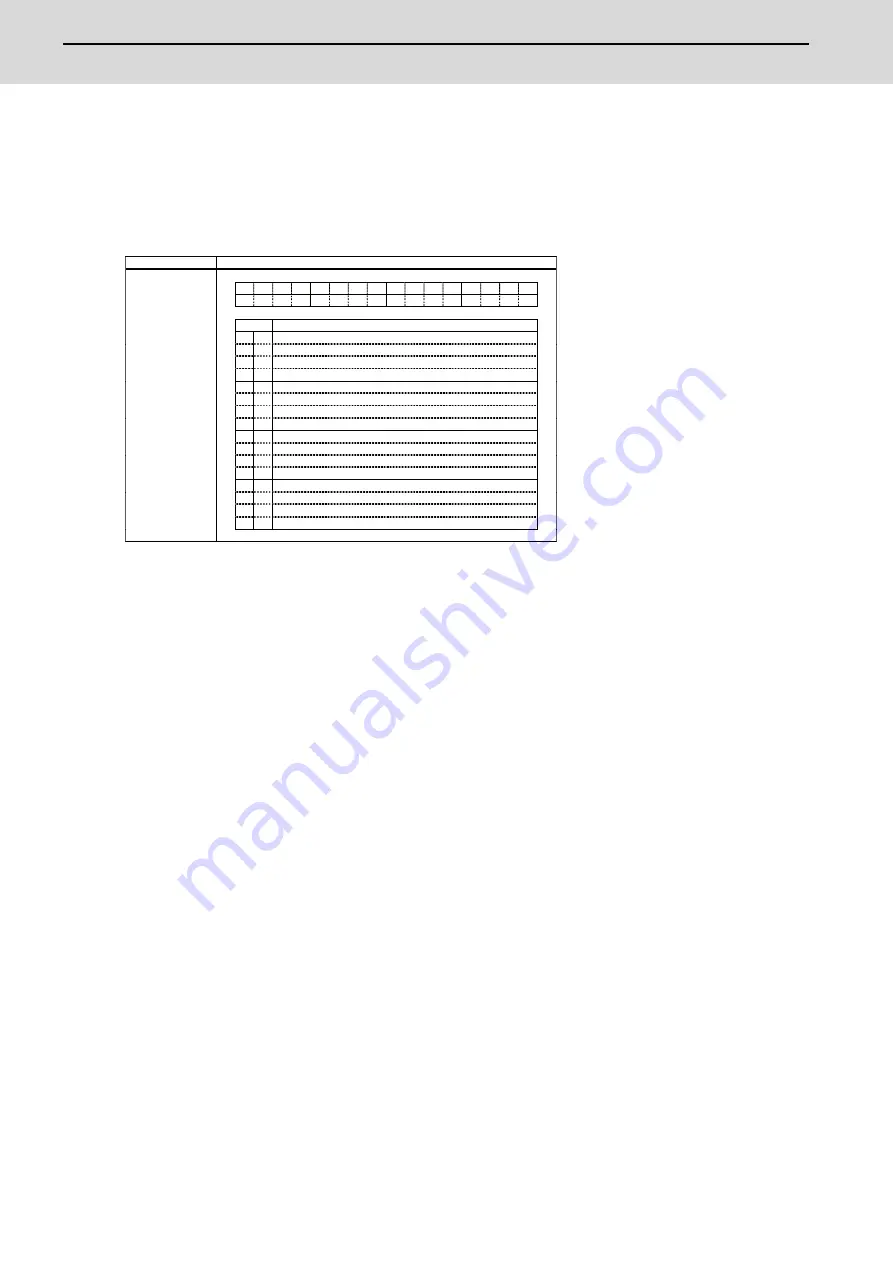

(1) Servo control input 1

bit0.

READY ON command (RDY)

Status turns to ready ON at RDY=1.

bit1.

Servo ON command (SRV)

[1] Drive unit turns ON at SRV=1 (servo ON status).

[2] Drive unit turns OFF at SRV=0 (servo OFF status).

bit4.

Position loop gain changeover command (KPM)

[1] The position loop gain (SV049/SV050/SV058) for spindle synchronous (synchronoustapping,

synchronous control with spindle C-axis, etc.) is selected at KPM=1.

[2] The normal position loop gain (SV003/SV004/SV057) is selected at KPM=0.

bit6.

Excessive error detection width changeover command (EOM)

[1] The excessive error width (SV053) for the special control (initial absolute position setting,stopper

control, etc.) is selected at EOM =1.

[2] The normal excessive error width (SV023) is selected at EOM =0.

bit7.

Alarm reset command (ALMR)

NR alarm is reset at ALMR=1.

bit8.

Current limit selection command (IL1)

[1] The current (torque) limit (SV014) for the special control (initial absolute position setting,stopper

control, etc.) is selected at IL1 =1.

[2] The normal current (torque) limit (SV013) is selected at IL1 =0.

(Note)

The bits other than those above are used for maintenance.

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

bit

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

RDY

SRV

-

-

KPM

-

EOM

IL1

-

-

-

-

-

-

-

RDY

SRV

KPM

EOM

ALMR

IL1

ALMR

Details

Name

Details

Servo control input 1

READY ON command

Servo ON command

(For maintenance)

Position loop gain changeover command

Excessive error detection width changeover command

Alarm reset command

Current limit selection command

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

(For maintenance)

Summary of Contents for MDS-E

Page 1: ......

Page 3: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 31: ......

Page 32: ...1 IB 1501229 F 1 Installation ...

Page 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Page 132: ...101 IB 1501229 F 3 Safety Function ...

Page 142: ...111 IB 1501229 F 4 Setup ...

Page 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Page 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Page 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Page 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Page 404: ...373 IB 1501229 F 7 Troubleshooting ...

Page 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Page 456: ...425 IB 1501229 F 8 Maintenance ...

Page 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Page 476: ...445 IB 1501229 F 9 Power Backup System ...

Page 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Page 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Page 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Page 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Page 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Page 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Page 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Page 550: ......

Page 554: ......