MDS-E/EH Series Instruction Manual

10 Appx. 1: Cable and Connector Assembly

466

IB-1501229-F

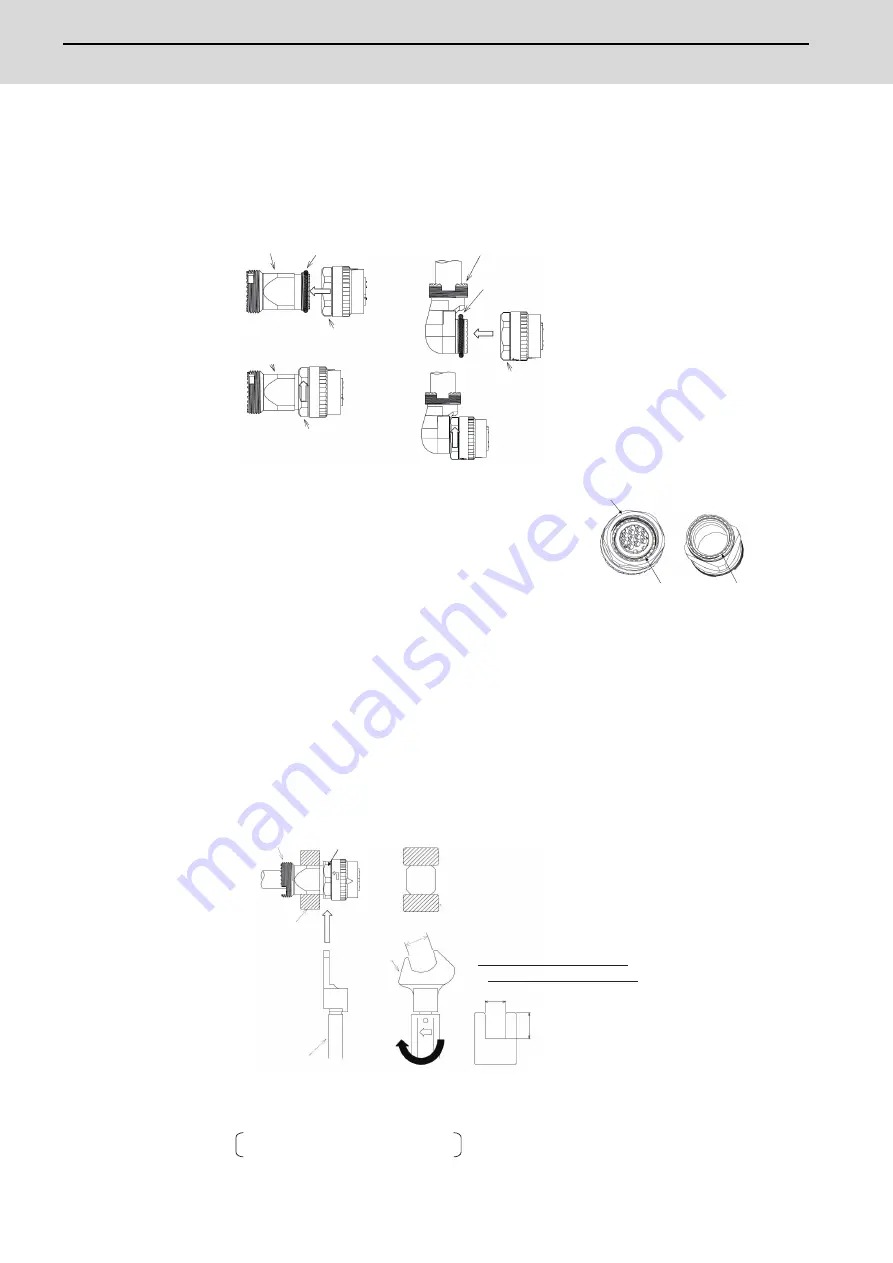

(6) Assembling a back shell

[1] To prevent the back shell from loosening, it is recommended to coat 2 threads of the circumference of the back

shell with adhesive.

Recommended adhesive: 1401B (Three Bond Co., Ltd.)

[2] Rotate the back shell coupling of the connector and temporarily tighten the back shell.

*

When tightening temporarily, match the concavity and convexity

of the plug shell with those of the back shell.

(You can confirm the correct connection of concavity and

convexity waving lightly back shell just before inserting to BS

coupling.)

(7) Tightening a back shell

Straight back shell

[1] Fix the 2 surface width of the straight back shell on the tightening guide.

[2] Set the tightening wrench adjusting to the back shell coupling.

[3] With the wrench, tighten the back shell coupling to the straight back shell.

Recommended tightening torque: 4 to 5N•m

(Note 1) When setting the work to the wrench, adjust it to the 2 surface width.

To remove, take the reverse steps.

(Note 2) Manufactured by DDK

Contact: Fujikura Ltd. http://www.fujikura.co.jp/eng/

Back shell

Back shell

Back shell coupling

Back shell coupling

Temporarily

tighten

Adhesive (to be coated to 2

threads of the circumference)

Angle back shell

Adhesive (to be coated to 2

threads of the circumference)

Insert

Back shell coupling

Insert

Temporarily tighten

Back shell coupling

Plug shell concavity

and convexity

Back shell concavity

and convexity

15

20

19

Back shell

Set

Tightening guide

Back shell

wrench

Tighten

(Back shell width)

Thickness:

10

* Referential dimensions for

back shell tightening guide

●

Bit (357J-51344T)

Torque wrench (CL6N x 8D,Tonichi Mfg.)

* Recommended tightening guide: (357J-53234T) (Note 2)

Back shell

coupling

Back shell

wrench

Tightening

guide

Recommended jigs and tools :

Back shell wrench (357J-51333T) (Note 2)

* Recommendation:

Tightening guide

(357J-53234T)

Summary of Contents for MDS-E

Page 1: ......

Page 3: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 31: ......

Page 32: ...1 IB 1501229 F 1 Installation ...

Page 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Page 132: ...101 IB 1501229 F 3 Safety Function ...

Page 142: ...111 IB 1501229 F 4 Setup ...

Page 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Page 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Page 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Page 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Page 404: ...373 IB 1501229 F 7 Troubleshooting ...

Page 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Page 456: ...425 IB 1501229 F 8 Maintenance ...

Page 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Page 476: ...445 IB 1501229 F 9 Power Backup System ...

Page 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Page 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Page 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Page 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Page 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Page 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Page 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Page 550: ......

Page 554: ......