MDS-E/EH Series Instruction Manual

1 Installation

19

IB-1501229-F

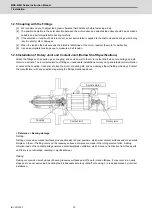

(c) Installation of coolant joint

Install the coolant joint to the motor shaft end so that it stops at the shaft edge. Stopping the coolant joint at the

edge of the inner diameter or at the screw bottom may generate an excessive radial runout, which may

generate abnormal noise or vibration.

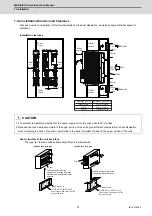

(3) Coupling

(a) Caution when selecting coupling

Always use a flexible coupling for coupling the spindle and the motor. The flexible coupling is flexible enough

to absorb a certain level of radial runout and parallel offset. The flexible coupling has tolerable values for three

degrees of freedom (parallel offset, angular misalignment, and axial movement), which realizes a low-vibration

and low-noise coupling up to high-speed rotation.

- Tolerable values of parallel offset and angular misalignment:

Absorbs minor misalignments or declinations that were not resolved during alignment.

- Tolerable value of axial movement:

Absorbs elongation of the spindle and motor shaft due to thermal expansion.

(These tolerable values are the standard values for which the coupling does not break. They are not the

standard values for which the load is not applied to the spindle or the motor bearing. Thus, in order to

rotate up to high-speed with low-vibration and low-noise, the spindle and the motor shaft must be

aligned.)

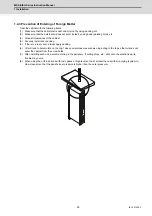

(b) Recommended model of coupling

The table below shows the recommended models manufactured by Miki Pulley and Eagle Industry.

(Note)

The diaphragm coupling in the table above absorbs the misalignment of the rotary axis with the

elastic deformation of the extremely thin metal diaphragm. In addition, there are the features as light

weight, no lubrication and high torsional stiffness, so it is recommended as a coupling of a high-

speed motor.

Company

Product name (or Series)

Contact

Miki Pulley

SERVO FLEX

https://www.mikipulley.co.jp/EN/

Eagle Industry

Diaphragm

https://www.ekkeagle.com/en/

Stop at the shaft edge

Stop at the edge of the

inner diameter

Stop at the screw bottom

Motor shaft

Coolant joint

Gap

Gap

Summary of Contents for MDS-E

Page 1: ......

Page 3: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 31: ......

Page 32: ...1 IB 1501229 F 1 Installation ...

Page 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Page 132: ...101 IB 1501229 F 3 Safety Function ...

Page 142: ...111 IB 1501229 F 4 Setup ...

Page 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Page 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Page 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Page 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Page 404: ...373 IB 1501229 F 7 Troubleshooting ...

Page 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Page 456: ...425 IB 1501229 F 8 Maintenance ...

Page 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Page 476: ...445 IB 1501229 F 9 Power Backup System ...

Page 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Page 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Page 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Page 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Page 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Page 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Page 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Page 550: ......

Page 554: ......