MDS-E/EH Series Instruction Manual

1 Installation

25

IB-1501229-F

1.3 Installation of Tool Spindle Motor

1.3.1 Environmental Conditions

1.3.2 Shaft Characteristics

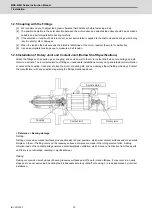

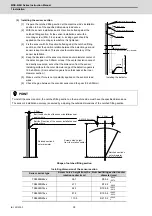

There is a limit to the load that can be applied on the motor shaft. Make sure that the load applied on the radial direction,

when mounted on the machine, is below the tolerable values given below. These loads may affect the motor output

torque, so consider them when designing the machine.

(Note 1) The tolerable radial load and thrust load in the above table are values applied when each motor is used

independently.

(Note 2) The symbol L in the table refers to the value of L below.

L: Length from flange installation surface to center of load mass [mm]

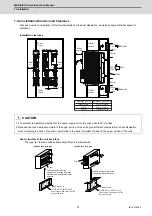

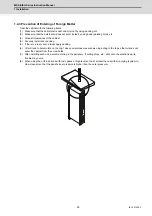

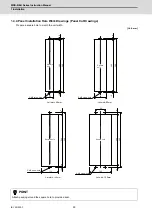

1.3.3 Installation of Tool Spindle Motor

Mount the servo motor on a flange which has the following size or produces an equivalent or higher heat dissipation

effect:

Environment

Conditions

Ambient temperature

0°C to +40°C (with no freezing)

Ambient humidity

80% RH or less (with no dew condensation)

Storage temperature

-15°C to +70°C (with no freezing)

Storage humidity

90% RH or less (with no dew condensation)

Atmosphere

Indoors (no direct sunlight)

No corrosive gas, inflammable gas, oil mist or dust

Altitude

Operation/storage: 1000m or less above sea level

Transportation: 10000m or less above sea level

Vibration

X:19.6m/s

2

(2G) Y:19.6m/s

2

(2G)

Series

Tool spindle motor

Tolerable radial load

Tolerable thrust load

200V

series

HG46S, HG46K, HG56S, HG56K

245N (L=30)

98N

HG-JR73, 153

323N (L=40)

284N

HG96S, HG96K

392N (L=40)

147N

HG75S, 105S

245N (L=33)

147N

HG54S, 104S, 154S, 224S

980N (L=55)

490N

HG204S, 354S, 453S, 703S

2058N (L=79)

980N

HG903S

2450N (L=85)

980N

400V

series

HG-JR734, 1534

323N (L=40)

284N

Flange size (mm)

Tool spindle motor capacity

250×250×6

400W

250×250×12

0.5 to 1.5kW

300×300×20

2.0 to 7.0kW

800×800×35

9.0kW

Radial load

Thrust load

L

Summary of Contents for MDS-E

Page 1: ......

Page 3: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 31: ......

Page 32: ...1 IB 1501229 F 1 Installation ...

Page 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Page 132: ...101 IB 1501229 F 3 Safety Function ...

Page 142: ...111 IB 1501229 F 4 Setup ...

Page 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Page 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Page 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Page 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Page 404: ...373 IB 1501229 F 7 Troubleshooting ...

Page 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Page 456: ...425 IB 1501229 F 8 Maintenance ...

Page 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Page 476: ...445 IB 1501229 F 9 Power Backup System ...

Page 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Page 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Page 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Page 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Page 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Page 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Page 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Page 550: ......

Page 554: ......