5. Base Specifications Parameters

II - 52

#

Items

Details

Setting range (unit)

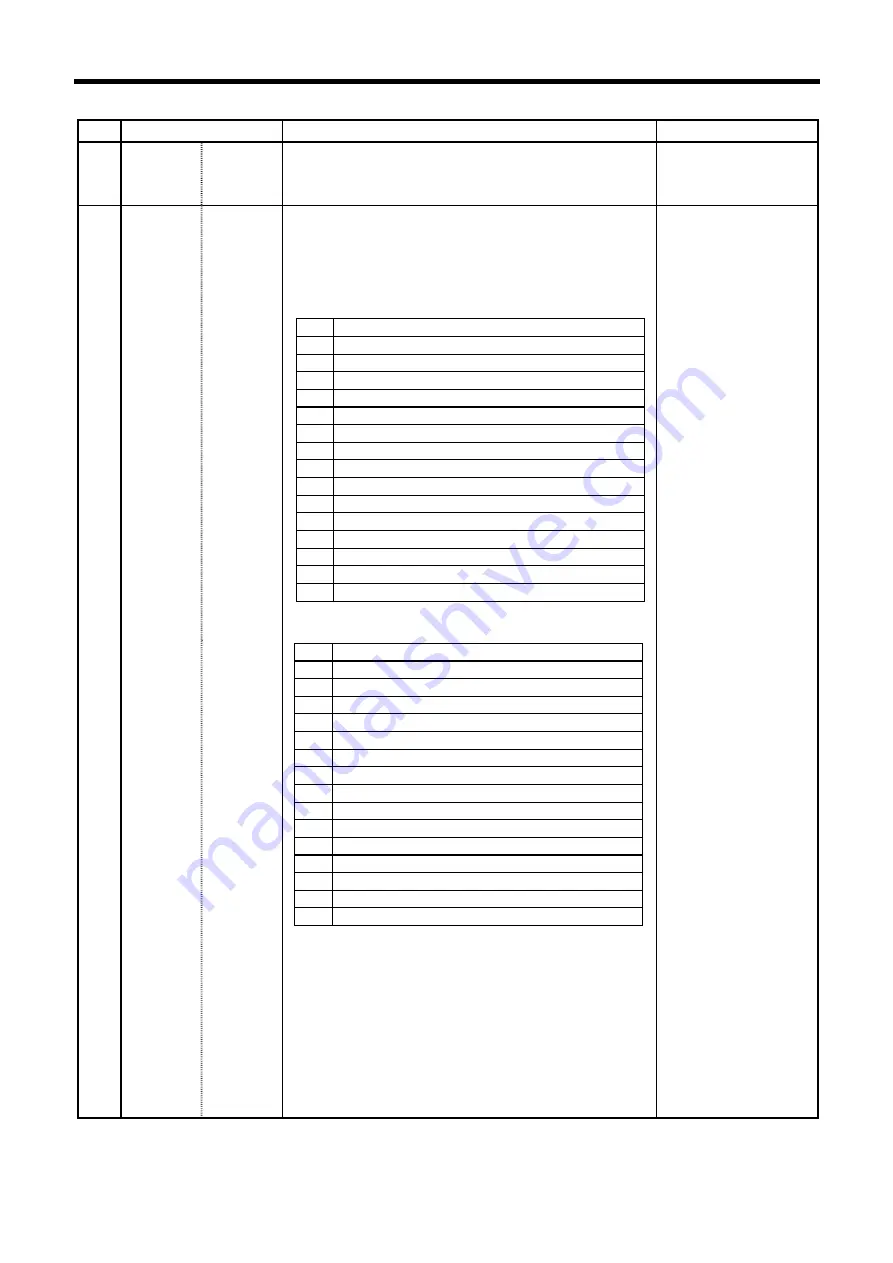

1209 cirdcc

Arc

decelerati

on speed

Specify the deceleration speed at the arc entrance or

exit.

1 to 999999 (mm/min)

1210 RstGmd

Modal G

code reset

Specify whether to initialize each G code group modal

and the H and D codes when the system is reset.

Specify the initialization items in bit correspondence.

0. Initialize. 1: Don't initialize.

M system

Specify a hexadecimal

number.

The H code indicates the tool length offset number, and

the D code indicates the tool radius compensation

number.

When bit 18 is set to ON, the H and D codes and group

8 G modal area retained.

When bit 7 is set to ON, the H code and group 8 G

modal are retained.

(To be continued to the next page)

10

Group 17 Constant surface speed control command modal

11 Group 18 pole coordinate command modal

12 Group 19 G command mirror modal

13 Group 20 Spindle 2 control modal

14

15

16

17

18 H, D codes

19 Spindle clamp rotation speed

1A

1B

1C

1D

1E

1F

0

Group 1 Move G modal

1

Group 2 Flat selection modal

2

Group 3 Absolute/increment command modal

3

4

Group 5 Feed G modal

5

Group 6 Inch/metric modal

6

Group 7 Radius compensation modal

7

Group 8 Length compensation modal

8

9

Group 10 Fixed cycle return command modal

A

B

Group 12 Workpiece coordinate system modal

C

Group 13 Cut modal

D

E

Grpup 15 Normal line control modal

F

Summary of Contents for MELDAS 60 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ......

Page 13: ...I EXPLANATION OF ALARMS ...

Page 14: ......

Page 95: ...II EXPLANATION OF PARAMETERS ...

Page 96: ......

Page 443: ......