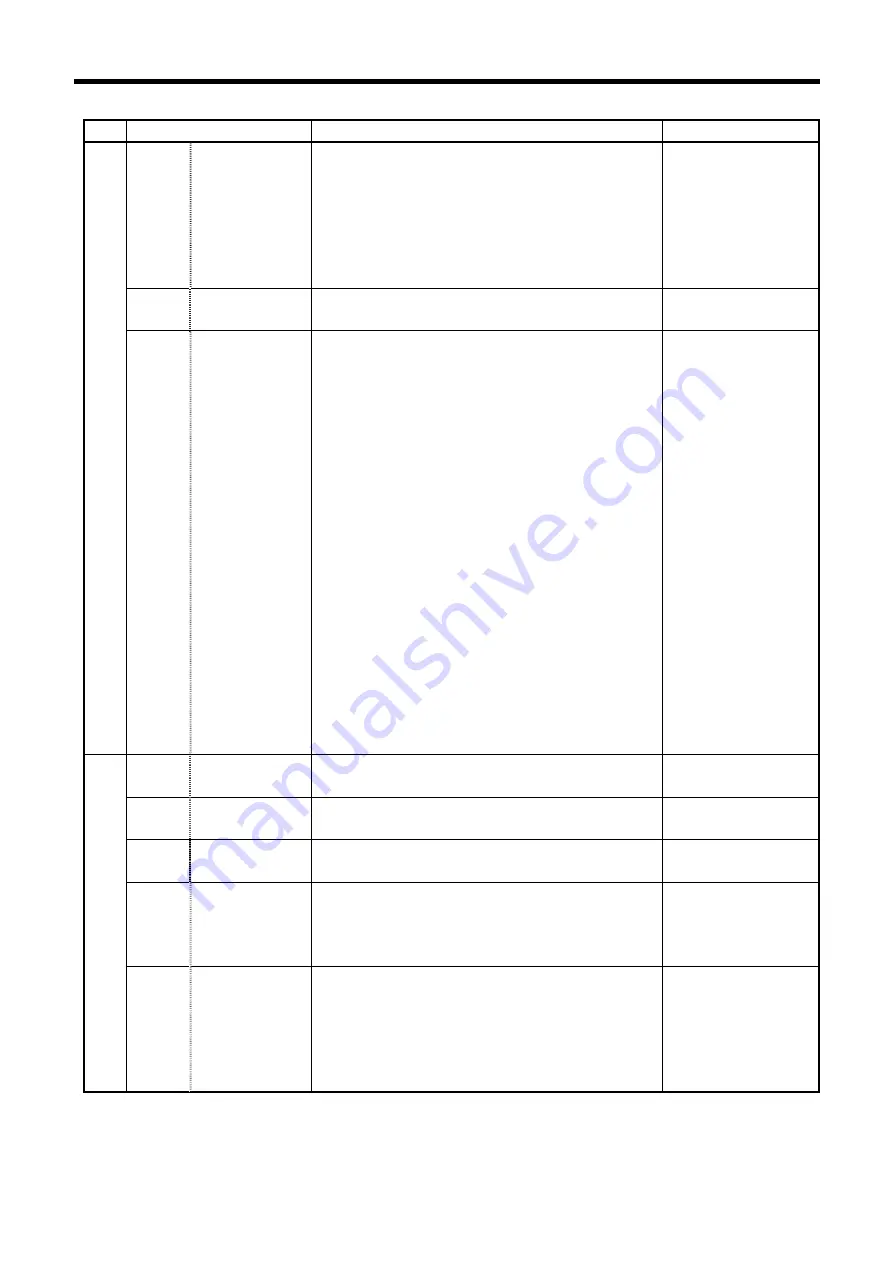

5. Base Specifications Parameters

II - 68

#

Items

Details

Setting range (unit)

set10

(bit0)

Switch G36

function

If a G code system containing the G36 (automatic

tool length measurement X) function is selected,

select whether to use G36 for the automatic tool

length measurement or arc thread cutting (CCW)

function.

0: Automatic tool length measurement

1: Arc thread cutting (CCW)

0/1

set10

(bit6)

Not

used.

0/1

1238

(PR)

set10

(bit7)

Switch operation

alarm

Select whether to validate the NC alarm 5 (AL5)

signal output.

0: NC alarm 5 (AL5) invalid

All operation alarms are output to NC alarm 4

(AL4).

All operation alarms are recorded in the

alarm history.

1: NC alarm 5 (AL5) valid

The following operation alarms are not output

to NC alarm 4 (AL4). These are output to NC

alarm 5 (AL5).

The operation alarms output to NC alarm 5

(AL5) are not recorded in the alarm history.

•

External interlock axis found

•

Cutting override zero

•

External feedrate zero

•

Block start interlock

•

Cutting block start interlock

•

Cutting interlock for spindle-spindle

polygon (G51.2)

0/1

(Default: 0)

1239

(PR)

set11

(bit0)

Coil switching

method

0: Via PLC. (Y2D7)

1: NC internal processing. (Y2D7 is invalid.)

0/1

set11

(bit1)

Not

used.

0/1

set11

(bit2)

Not

used.

0/1

set11

(bit3)

Polygon

machining mode

at reset

Select whether to cancel the polygon machining

mode when reset is applied.

0: Do not cancel.

1: Cancel.

0/1

set11

(bit4)

Invalidate G51.1

phase command

Select whether to carry out phase control with the

spindle-spindle polygon function.

0: Always validate phase control.

* When R is not commanded, it is handled as

R0.

1: Validate phase control only at R command

0/1

Summary of Contents for MELDAS 60 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ......

Page 13: ...I EXPLANATION OF ALARMS ...

Page 14: ......

Page 95: ...II EXPLANATION OF PARAMETERS ...

Page 96: ......

Page 443: ......