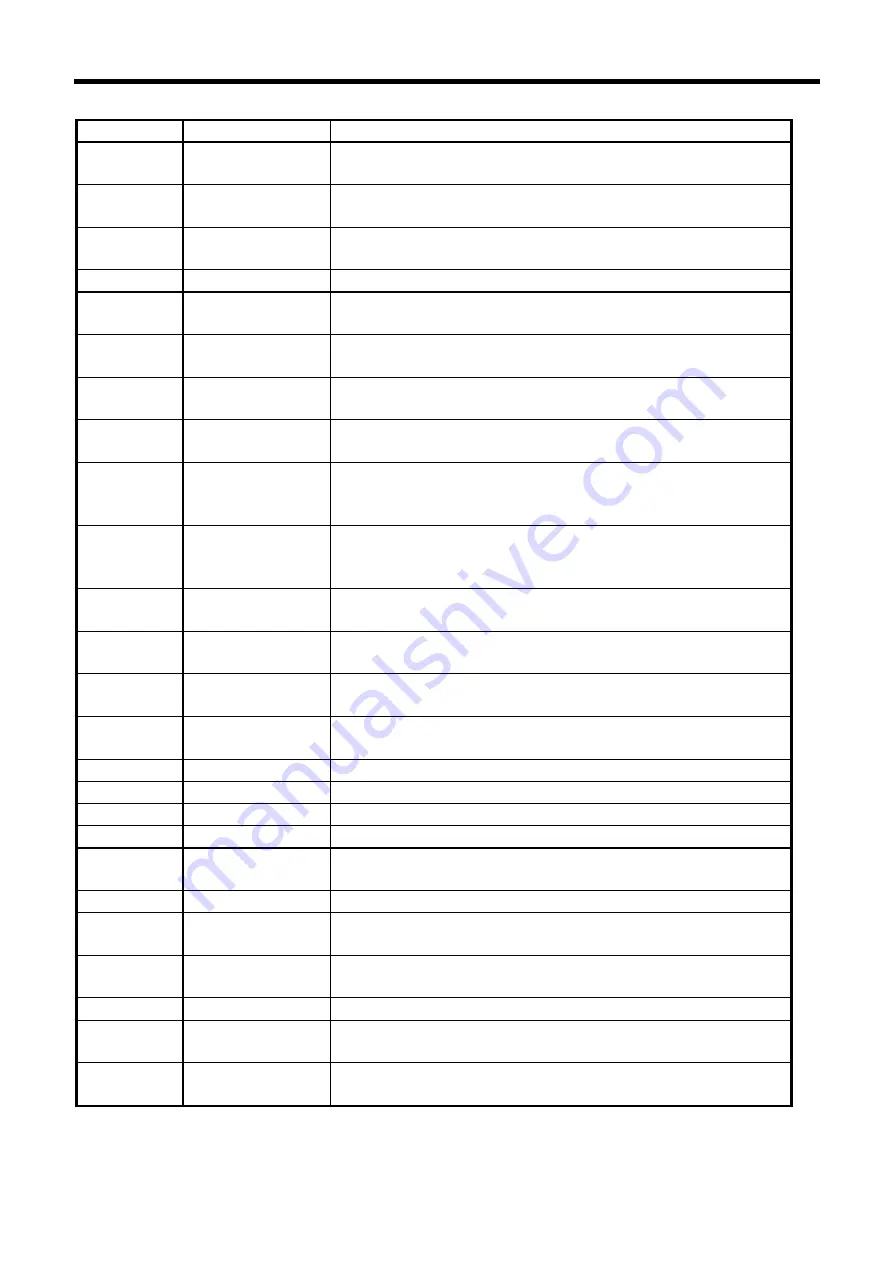

1. List of Alarms

1.3 Servo spindle Alarms

I - 18

Alarm No.

Name

Meaning

53

Excessive error 2

A difference between the actual and theoretical motor positions

during servo OFF exceeded the setting value.

54

Excessive error 3

When an excessive error 1 occurred, detection of the motor current

failed.

55

External emergency

stop error

There is no contactor shutoff command, even after 30 seconds has

passed since the external emergency stop was input.

57

Option error

An invalid option function was selected.

58

Collision detection 1:

G0

When collision detection function was valid, the disturbance torque

in rapid traverse (G0) exceeded the collision detection level.

59

Collision detection 1:

G1

When collision detection function was valid, the disturbance torque

in cutting feed (G1) exceeded the collision detection level.

5A

Collision detection 2 When collision detection function was valid, the command torque

reached the max. motor torque.

5C

Orientation feedback

error

After orientation was achieved, a difference between the command

and feedback exceeded the parameter setting.

5D

Speed monitoring:

Input mismatch

As for door state signal of speed monitoring control, a mismatch

between the external input signal and the control signal received

from the CNC was detected.

5E

Speed monitoring:

Feedback speed

error

In speed monitoring control, the spindle speed was exceeding the

setting speed with the door open.

5F

External contactor

error

A contact of the external contactor is welding. Or the contactor fails

to be ON during ready ON.

61

Power module

overcurrent

Overcurrent protection function in the power module has started its

operation.

62

Frequency error

The input power supply frequency increased above the specification

range.

63

Supplementary

regeneration error

The supplementary regenerative transistor is being ON.

65

Rush relay error

A resistor relay for rush short circuit fails to be ON.

67

Phase interruption

An open-phase condition was detected in input power supply circuit.

68

Watchdog

The system does not operate correctly.

69

Grounding

The motor power cable is in contact with FG (Frame Ground).

6A

External contactor

welding

A contact of the external contactor is welding.

6B

Rush relay welding

A resistor relay for rush short circuit fails to be OFF.

6C

Main circuit error

An error was detected in charging operation of the main circuit

capacitor.

6D

Parameter error

The capacity of the power supply unit and the regenerative resistor

type that was set in the parameter are mismatched.

6E

Memory error

An internal memory error was detected.

6F

Power supply error

A power supply unit is not connected. Or an error was detected in

A/D converter of the power supply unit.

71

Instantaneous

power interruption

The power was momentarily interrupted.

Summary of Contents for MELDAS 60 Series

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ......

Page 13: ...I EXPLANATION OF ALARMS ...

Page 14: ......

Page 95: ...II EXPLANATION OF PARAMETERS ...

Page 96: ......

Page 443: ......