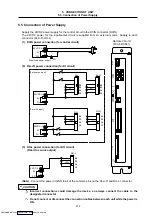

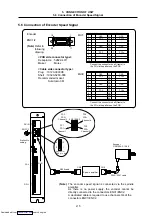

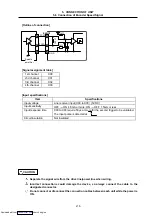

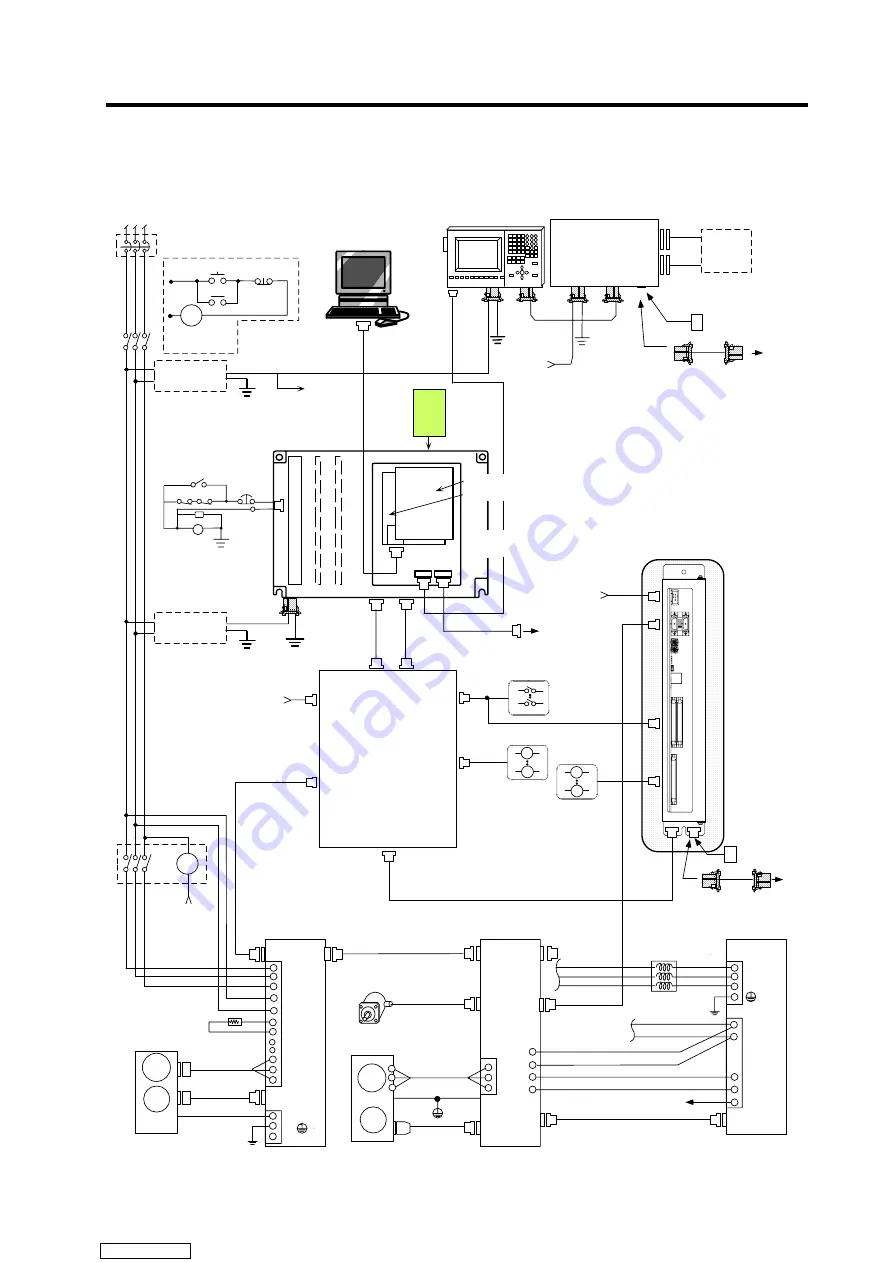

4. SYSTEM CONNECTION

4.1 General System Diagram

I

-9

4. SYSTEM CONNECTION

4.1 General System Diagram

F G

SV1

CF10

CF11

R000

MC1

MC1

MC1

CF11

CF10

AUX2

EMG

BASE-T

F010

F050

R000

ON

OF F

MC

MC

R S T

MC

FG

F G

RA

MDS-B-SVJ2-

∗∗

MDS-B-SP-

∗∗∗

IM

CN1A CN1B

L1

L2

L3

L+

L-

MC1

L11

L21

SH21

CN5

CN4

OSA253S

MR-RB

O30

CN2

CN1A CN1B

L1

L2

L3

C

P

N

D

U

V

W

F

G

L11

L21

F G

F G

U

V

W

L+

L-

L1

L2

CN4

L1

L2

L3

L11

L21

SM

1.5kW

MC1

CN6

DC24IN

AUX1

CPU:HR114/146

FG

CR02

CR01

CR05

FG

CT100/CT120/LD100/DUT32/DUN33

/EL10/CR10

RIO1

MJ2

MJ3

CN8

R

R

R

R

4

4

RIO1RIO2

DCIN

RIO1 RIO2

F120

EMG

R211

R211

R211

R211

R220

R220

24VDC( +)

MDS-B-CV-

∗

Stabilized

power supply

Base I/O unit

HR377/HR378

FCU6-DX3

FCU6-DX4

MC link B

Terminator

R-TM

Machine control contact

To next remote

I/O unit

Operation

panel

Remote I/O unit

DX1

Communication terminal

MC link B terminator

R-TM

MDS-B-CVE-

∗

To next remote

I/O unit

Ethernet

communication device

3-phase 200VAC to 230VAC

No fuse breaker (NFB)

OT rel ease swit ch

In sert

when required

X axis and Y axis

Spindle

AC

servomotor

with detector

HC153TA33

Spindle motor

SJ-V15-02

R056 cable

7.5kW rating 30 min.

Regenerative

resist or

CNV2/CNV12

cable

Terminator

MDS-A-TM

AC reactor B-AL

Spindle encoder

SE1024-3-15-68

De te c-

tor

De tec-

tor

Converter

24VDC( +)

24VDC( +)

or

Power

supply

HR083

Op tion slot

RT2 RT1

IC card

Control unit

M60/M600 Series

24VDC

IC card: HR831

Ethernet: HR832

Communication card

HR171

PLC unit

FCU6-DX561

24VDC( +)

or

Machine control relay

FG

24VDC( +)

24VDC (+)

Stabilized

power supply

I/O link

To next

control unit

DCIN

ENC1/

ENC2

DI-L/

DI-R

DO-L

(Note)

This drawing is an example of the general connection for the M60/M600 Series. The actual

connection will differ according to the specifications.

Downloaded from