Chapter 10 Adjustment

10–7

10-3 Characteristics improvement

10-3-1 Optimal adjustment of cycle time

The following items must be adjusted to adjust the cycle time. Refer to the Instruction Manuals

provided with each CNC for the acceleration/deceleration pattern.

1) Rapid traverse rate (rapid)

: This will affect the maximum speed during positioning.

2) Clamp speed (clamp)

: This will affect the maximum speed during cutting.

3) Acceleration/deceleration

time

:

Set the time to reach the feedrate.

constant (G0t*, G1t*)

4) In-position width (SV024)

: This will affect each block's movement command end time.

5) Position loop gain (SV003)

: This will affect each block's movement command settling time.

(1) Adjusting the rapid traverse rate

To adjust the rapid traverse, the CNC axis specification parameter rapid traverse rate (rapid) and

acceleration/deceleration time constant (G0t*) are adjusted. The rapid traverse rate is set so that

the motor speed matches the machine specifications in the range below the maximum speed in

the motor specifications. For the acceleration/deceleration time constants, carry out rapid traverse

reciprocation operation, and set so that the maximum current command value at

acceleration/deceleration is within the range shown below.

When adjusting, watch the current FB waveform during acceleration/deceleration, and adjust so

that the thrust is within the specified range. Be careful, as insufficient thrust can easily occur when

the driver input voltage is low (170 to 190V), and an excessive error can easily occur during

acceleration/deceleration.

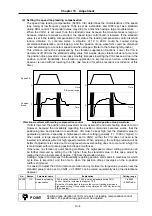

(2) Adjusting the cutting rate

To adjust the cutting rate, the CNC axis specification parameter clamp speed (clamp) and

acceleration/deceleration time constant (G1t*) are adjusted. The in-position width at this time

must be set to the same value as actual cutting.

• Determining the clamp rate and adjusting the acceleration/deceleration time constant

(Features)

The maximum cutting rate (clamp speed) can be determined freely.

(Adjustment)

Carry out cutting feed reciprocation operation with no dwell at the maximum

cutting rate and adjust the acceleration/deceleration time constant so that the

maximum current command value during acceleration/deceleration is within the

range shown below.

• Setting the step acceleration/deceleration and adjusting the clamp speed

(Features)

The acceleration/deceleration time constant is determined with the position loop

in the servo, so the acceleration/deceleration F

∆

T can be reduced.

(Adjustment)

Set 1 (step) for the acceleration/deceleration time constant and carry out cutting

feed reciprocation operation with no dwell. Adjust the cutting feed rate so that

the maximum current command value during acceleration/deceleration is within

the range shown below, and then set the value in the clamp speed.

Self-cooling Oil-cooling

Motor type

Max. current

command value

Motor type

Max. current

command value

LM-NP2S-05M

600 to 680%

LM-NP2S-05M

270 to 310%

LM-NP2M-10M

590 to 670%

LM-NP2M-10M

275 to 310%

LM-NP2L-15M

565 to 640%

LM-NP2L-15M

270 to 306%

LM-NP4S-10M

590 to 670%

LM-NP4S-10M

275 to 312%

LM-NP4M-20M

550 to 620%

LM-NP4M-20M

262 to 300%

LM-NP4L-30M

570 to 650%

LM-NP4L-30M

272 to 310%

LM-NP4G-40M

560 to 640%

LM-NP4G-40M

271 to 307%