Chapter 10 Adjustment

10–15

<Adjustment method>

First confirm whether the axis to be compensated is an unbalance axis (vertical axis, slant axis). If

it is an unbalance axis, carry out the adjustment after performing step "(2) Unbalance thrust

compensation".

Next, measure the frictional torque. Carry out reciprocation operation (approx. F1000) with the

axis to be compensated and measure the load current % when fed at a constant speed on the

CNC servo monitor screen. The frictional force of the machine at this time is expressed with the

following expression.

Frictional force % =

(+ feed load current %) – (– feed load current %)

2

The standard setting value for the lost motion compensation 1 (LMC1) is double the frictional

torque above.

Assume that the load current % was 25% in the + direction and –15% in the –

direction when JOG feed was carried out at approx. F1000. The frictional force is as

shown below, so 20%

×

2 = 40% is set for LMC1. (LMC2 is left set at 0.) With this

setting, 40% compensation will be carried out when the command reverses from the +

direction to the - direction, and when the command reverses from the – direction to the

+ direction.

25 – (–15)

2

= 20%

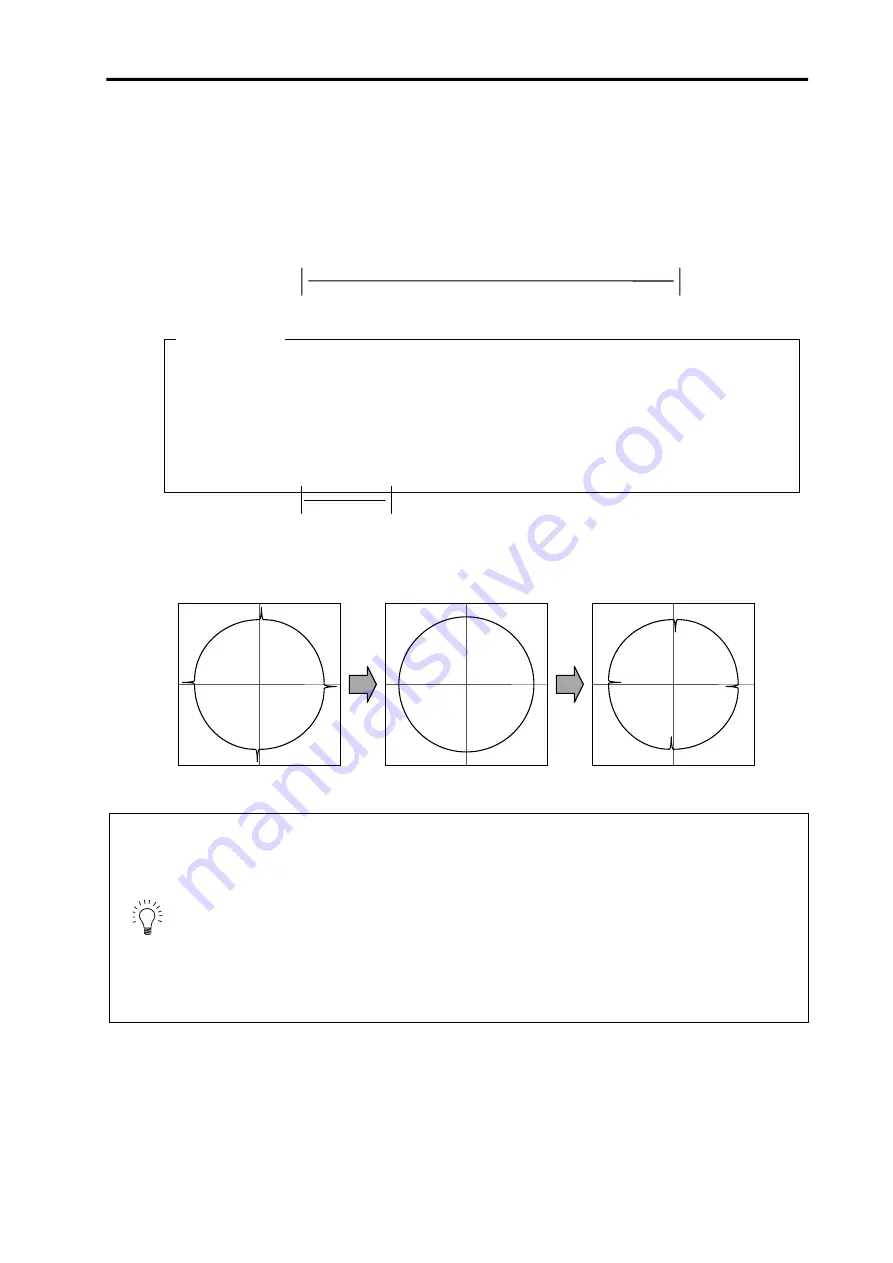

For the final adjustment, measure the CNC sampling measurement (DBB measurement) or while

carrying out actual cutting. If the compensation amount is insufficient, increase LMC1 or LMC2 by

5% at a time. Note that if the setting is too high, biting may occur.

Compensation 0 Optimum Too high

POINT

1. When either parameter SV016: LMC1 or SV041: LMC2 is set to 0, the same

amount of compensation is carried out in both the positive and negative

direction with the setting value of the other parameter (the parameter not set

to 0).

2. To compensate in only one direction, set -1 in the parameter (LMC1 or

LMC2) for the direction in which compensation is prohibited.

3. The value set based on the frictional force is the standard value for LMC

compensation. The optimum compensation amount changes with the

cutting conditions (cutting speed, cutting radius, blade type, workpiece

material, etc.). Be sure to ultimately make test cuts matching the target

cutting and determine the compensation amount.

(Example)