Chapter 1 Outline

1–2

1-1 Outline

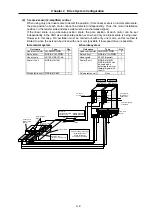

In recent years, demands for high accuracy, high speed and high efficiency have increased in the field

of machine tools. The application of a linear servo for the feed axis has increased as a measure to

respond to the demands.

With the linear servo system, high speed and high acceleration characteristics can be achieved in

respect to the ball screw drive system. Furthermore, as there is no ball wear, etc., which is the

disadvantage of using a ball screw drive, the life of the machine can be extended. A response error

caused by backlash or wear does not occur, so a high accuracy system can be structured.

The MELDAS linear servo system has been developed to realize a max. speed of 120m/min and

acceleration of 98m/s

2

(motor unit) as a standard.

1-2 Features

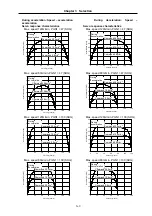

(1) Ample lineup (Seven models)

Machines can be handled flexiblely. Thus, thrust can be increased by using several motors for

one axis.

(2) High speed and high acceleration

The max. speed is 2m/s as a standard. An acceleration of 98m/s

2

is possible with the motor unit.

(3) Absolute position detection system

As the absolute position detection system, the Mitsutoyo linear scale AT342 and Heidenhain

absolute position linear scale LC191M are compatible with the MELDAS high-speed serial

communication specifications. (Both are battery-less)

(4) High performance servo drive

Compared to the conventional amplifier MDS-B-Vx, the servo processing performance has been

greatly improved. The high-gain servo MDS-B-V14L has been developed to achieve high speed

and more accurate machining in combination with the high frequency PWM control. Linear servo

systems requiring a higher speed and accuracy are powerfully backed up by the high-gain servo

MDS-B-V14L.