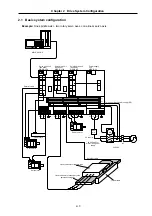

Chapter 2 Drive System Configuration

2–4

CAUTION

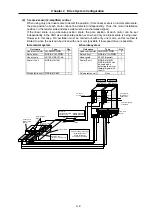

1. In a system having a spindle drive unit, always place the spindle drive unit

next to the power supply unit as shown in the drawing. Also, place the servo

drive unit 11kW and above next to the power supply unit.

2. When also using a spindle drive unit, place the units next to the power

supply unit in order of the drive capacity size.

3. The use of the contactor installation can be selected except for the

MDS-B-CV-370.

4. Use without a contactor is possible, except for the MDS-B-CV-370.

However, for safety purposes, use of a contactor is recommended.

Set the rotary switch on the power supply unit as follows according to

whether the contactor is used.

With contactor

・・・・・・

Rotary switch setting = 0

Without contactor

・・・

Rotary switch setting = 1

For the MDS-A-CR, the rotary switch is fixed to 0. Always install a contactor.

5. Always install an AC reactor (shipped from Mitsubishi). Note that this is not

required for the A-CR. Wire the AC reactor to the front (NF side) of the

contactor.

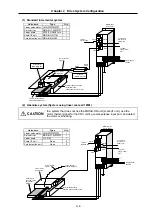

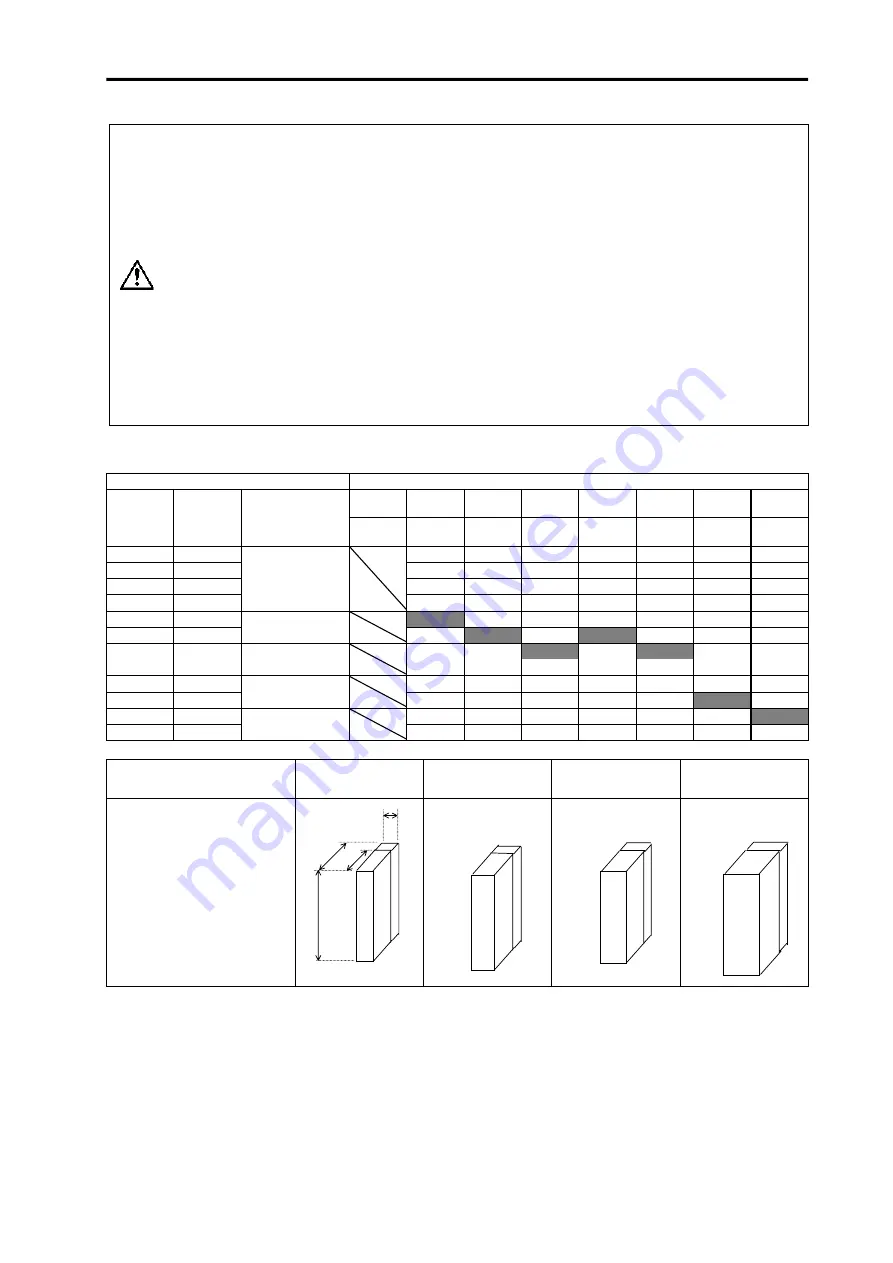

2-2 List of units and corresponding linear motors

Linear servo amplifier

Corresponding servo amplifier (LM-

)

Type

NP2S-05

M

NP2M-1

0M

NP2L-15

M

NP4S-10

M

NP4M-2

0M

NP4L-30

M

NP4G-4

0M

Type

MDS-B-

Capacity

Outline

H×W×D (mm)

Outline

dimension types

Max.

thrust

1500N 3000N 4500N 3000N 6000N 9000N 12000N

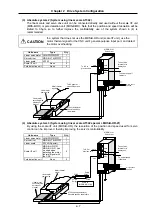

V14L-01

0.1kW

V14L-03

0.3kW

V14L-05

0.5kW

V14L-10 1.0kW

380×60×180

A0 type

V14L-20 2.0kW

V14L-35 3.5kW

380×60×300

A1 type

V14L-45 4.5kW

380×90×300

B1 type

V14L-70

7.0kW

V14L-90 9.0kW

380×120×300

C1 type

V14L-110

11.0kW

V14L-150 15.0kW

380×150×300

D1 type

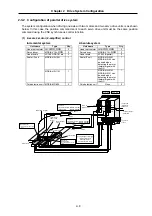

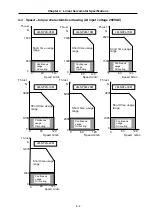

Outline dimension and

outline type of each unit

A0/A1

B1 C1 D1

Outline drawing

(mm)

W:60

Fin section D:120

D:300

180

H:380

Fi

n

The A0 type does not have

a fin. (Depth 180)

W:90

Fin 120

D:300

H:380

W:120

Fin 120

D:300

H:380

W:150

Fin 120

D:300

H:380