V

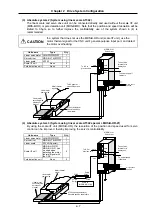

CAUTION

Always use nonmagnetic tools when installing the linear servomotor.

Always mount a mechanical stopper on the end of the linear servomotor's travel path to avoid

danger if the motor should go over the end.

Securely fix the linear servomotor onto the machine. Insufficient fixing could cause the

servomotor to come off during operation.

Provide a cover on the movable sections of the linear servomotor so that they are never

touched during operation.

When storing for a long time, please contact your dealer.

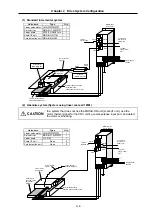

(2) Wiring

CAUTION

Correctly and securely perform the wiring. Failure to do so could lead to runaway of the

servomotor.

Do not install a phase advancing capacity, surge absorber or radio noise filter on the output side

of the servo amplifier.

Correctly connect the output side (terminals U, V, W). Failure to do so could lead to abnormal

operation of the servomotor.

Do not directly connect a commercial power supply to the linear servomotor. Doing so could

lead to faults.

Make sure not to mistake the orientation of the surge absorbing diode installed on the DC

relay for the control output signal. Failure to do so could cause a trouble preventing the signal

from being output, or could inhibit operation of the protection circuit during an emergency

stop, etc.

Do not connect/disconnect the cables connected between each unit while the power is ON.

Securely tighten the fixing screws and fixing mechanisms on the cable connectors.

Insufficient fixing could cause the connectors to dislocate during operation.

Ground the shield cables indicated in the Connection Manual with a cable clamp, etc.

Separate the signal wire away from the power line/electricity line.

Use wires and cables having a wire diameter, heat resistance and bending characteristics

compatible for the system.