Chapter 9 Setup

9–2

9-1 Initial setup of servo drive unit

9-1-1 Setting the rotary switches

Before turning ON the power, the axis No. must be set with the rotary switches. The rotary switch

settings will be validated when the servo driver (servo drive unit) power is turned ON.

MDS-B-V14L

POINT

When an axis that is not used is selected, that axis will not be controlled when

the power is turned ON, and "Ab" will remain displayed on the LED.

If the power of the axis not in use is disconnected, the system's emergency

stop cannot be released.

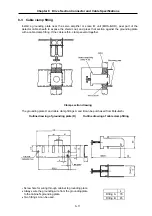

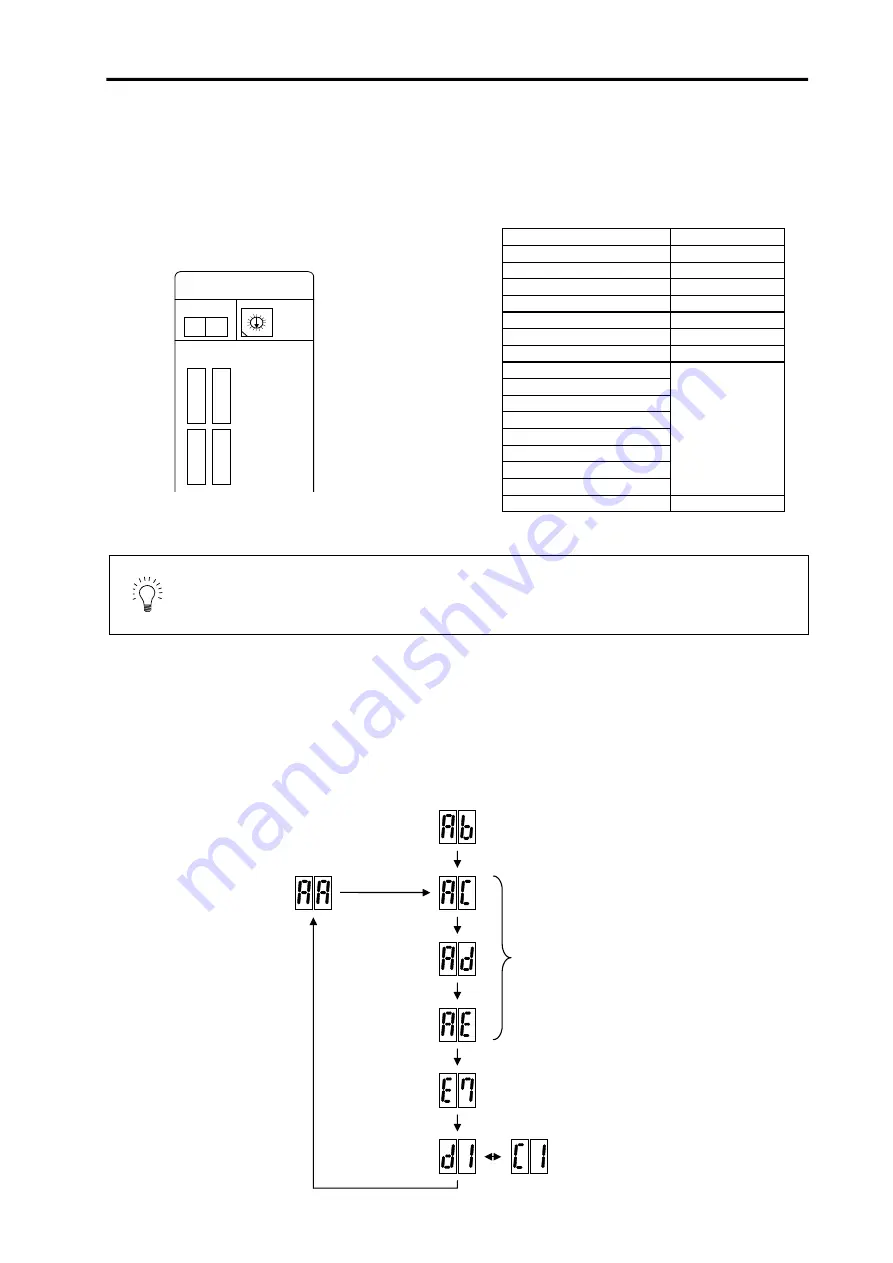

9-1-2 Transition of LED display after power is turned ON

When the axis No. has been set and the servo driver power and CNC power have been turned ON,

the servo driver will automatically execute self-diagnosis and initial settings for operation, etc. The

LEDs on the front of the servo driver will change as shown below according to the progression of

these processes.

If an alarm occurs, the alarm No. will appear on the LEDs. Refer to "Chapter 11 Troubleshooting" for

details on the alarm displays.

Rotary switch setting

Set axis No.

0 1st

axis

1 2nd

axis

2 3rd

axis

3 4th

axis

4 5th

axis

5 6th

axis

6 7th

axis

7

8

9

A

B

Not usable

C

D

E

F

Axis not used

Waiting for CNC

power start up

CNC power ON

LED display

Servo driver initialization complete

Waiting for CNC power start up

Executing initial communication with CNC

Emergency stop state

The LED will alternate between

F#

→

E7

→

not lit. (# is the set axis No.)

Servo ON state

CNC power OFF

Servo OFF state

Repeats lighting and going out.

(1st axis in the display example)

CNC power ON