10

JEP0-IL9555

2. RUN display (Self-monitoring function)

This relay monitors control voltage, electric

circuit, and program data at all time. The RUN LED

(green) lights up in the normal condition.

In the abnormal condition, the RUN LED goes out and

the error message

E r r

is displayed on the

numerical display LED, with the output contact

locked.

3. Numerical display function

By switching the position of the indicator select

switch, following items can be displayed on the

numerical display LED.

①

I

0

current measurement

The display shows the value of zero-sequence

current. The display range is from 0.05A to 1.5A.

(If input current is less than 0.05A, the display

goes out. If input current is more than 1.5A, the

error message

O

.

F

. is displayed.)

②

Pickup

When input zero-sequence current is greater than

or equal to the setting value,

I

. is displayed.

This function can be used for operation value tests.

③

Setting value

It displays the setting condition of the relay

including I

0

operation value and operating time

setting.

④

Frequency setting

It displays the setting condition of frequency in

accordance with the setting switch of SW1.

⑤

Output contact setting (MGR-A3V-R only)

It displays the setting condition of output contact

in accordance with the setting switch of SW2.

The setting is self-hold, the display shows

Ho

..

The setting is auto-reset, the display shows

FU

..

4. Fault record function

①

Display of fault records

When a fault occurs, the relay outputs the

operating signal, and at the same time the input

value of zero-sequence current is recorded. When

the indicator select switch is set to the position

of fault record, the records are displayed starting

from the latest record to the oldest one at

approximately 2 second intervals. The relay can

save the newest five phenomena.

The records are saved in the non-volatile memory,

therefore the records can be read again after

shutting the power off.

Note that the fault record may not be saved if the

auxiliary power supply is turned off soon after

the relay operation.

②

Clearing of fault records

Set indicator select switch to "CLEAR FAULT REC."

and hold for 5s or more, then

O

.

K

. is displayed

and all of the fault record are cleared.

5. Display function of setting change

When a setting is changed, the setting value after

changing is displayed for approx. 3s preferentially.

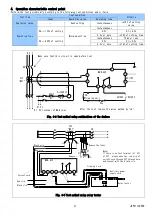

Internal connection diagram

B1

B2

c

b

X0

a

Z1

Z2

Continuous

monitoring

Power circuit

monitoring

Operation

indicator

RUN indicator

Output

contact

X0

Level

assessment

Power supply

P1

P2

I

0

X1

E

Auxiliary

power

supply

X1

Output

contact

a

)

MGR-A3V-R

B1

B2

T1

T2

X0

O1

O2

S2

S1

SO

X0

X0

X1

L

E

Z1

Z2

Continuous

monitoring

Power circuit

monitoring

Operation

indicator

RUN indicator

Output

contact

X0

Level

assessment

Power supply

P1

P2

I

0

Auxiliary

power

supply

X1

Output

contact

b

)

MGR-A3T-R

Fig. 3-2 Internal connection diagram