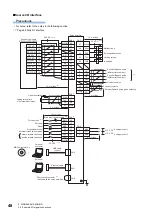

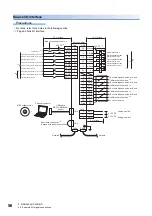

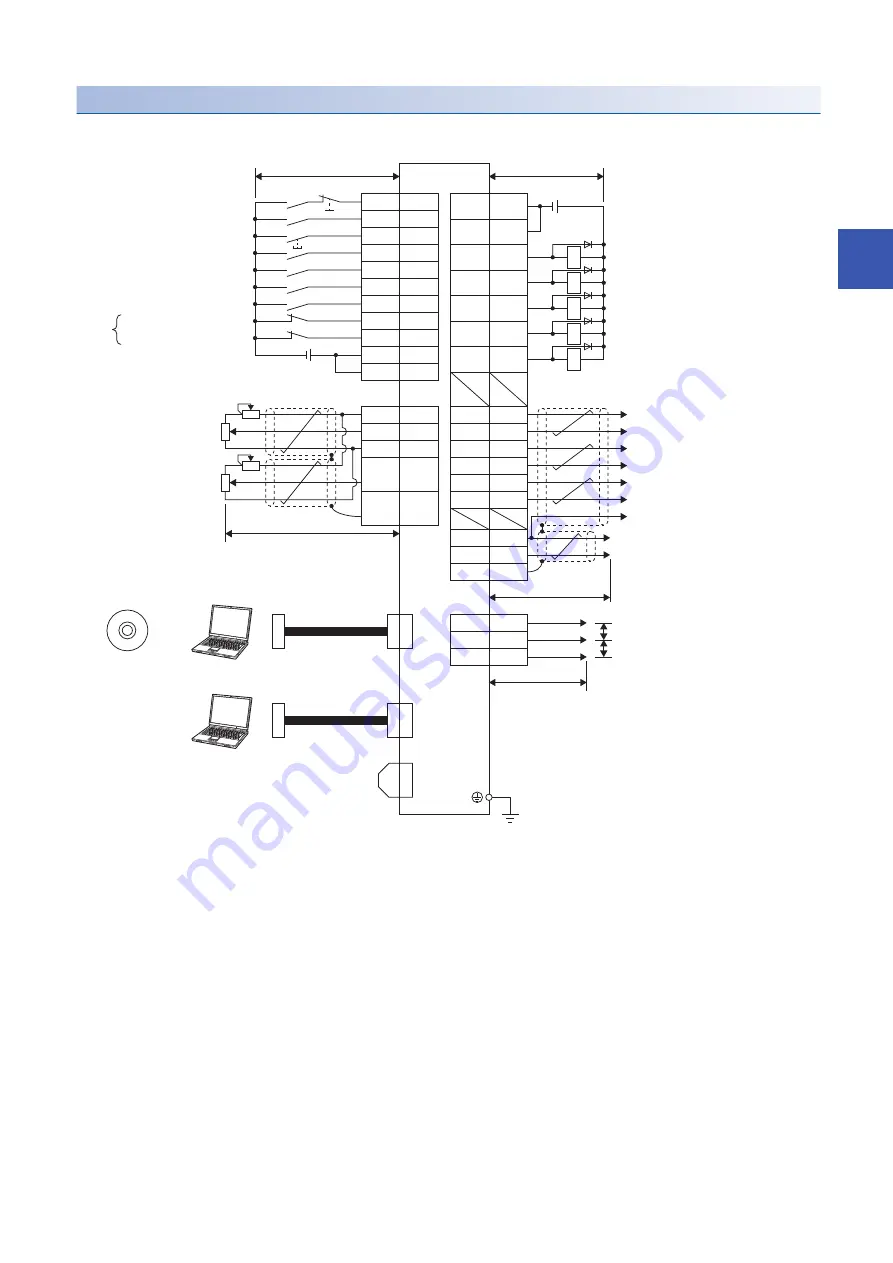

3 SIGNALS AND WIRING

3.2 Example I/O signal connections

49

3

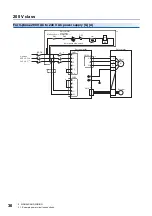

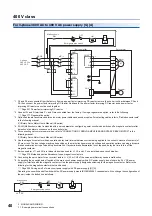

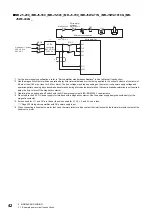

Speed control mode

■

Sink I/O interface

46

DOCOM

48

ALM

23

ZSP

25

TLC

24

SA

4

LA

5

LAR

6

LB

7

LBR

34

LG

33

OP

SD

CN3

*7

42

15

19

17

18

43

44

21

EM2

SON

RES

ST1

ST2

LSP

LSN

DICOM

CN3

*7

CN3

*7

1

2

SD

P15R

VC

LG

28

CN8

*1

MO1

MO2

3

LG

1

2

CN6

*2

RA2

RA3

RA4

RA1

47

DOCOM

49

RD

8

LZ

9

LZR

41

SP1

16

SP2

20

DICOM

*5

TLA

27

RA5

CN5

CN1

MR Configurator2

*9

+

Servo amplifier

10 m or less

10 m or less

Main circuit power supply

*11

24 V DC

*4

Forced stop 2

*3*5

Servo-on

Reset

Speed selection 1

Malfunction

*6

Speed selection 2

Zero speed detection

Forward rotation start

Reverse rotation start

Limiting torque

Forward rotation stroke end

Speed reached

Reverse rotation stroke end

Ready

24 V DC

*4

Upper limit setting

Encoder Z-phase pulse

(differential line driver)

Analog speed command

±10 V/rated speed

Encoder A-phase pulse

(differential line driver)

Upper limit setting

Analog torque limit

*8

+10 V/maximum torque

Encoder B-phase pulse

(differential line driver)

Plate

Control common

2 m or less

Encoder Z-phase pulse (open collector)

Plate

2 m or less

Analog monitor 1

Analog monitor 2

2 m or less

Short-circuit connector

*10

(Packed with the servo amplifier)

USB cable

Personal

computer

Personal

computer

Ethernet cable

(option)

± 10 V DC

± 10 V DC

Summary of Contents for MELSERVO-J5 MR-J5-G Series

Page 2: ......

Page 473: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 471 12 MEMO ...

Page 477: ......