3 SIGNALS AND WIRING

3.3 Explanation of power supply system

61

3

Connecting wires

■

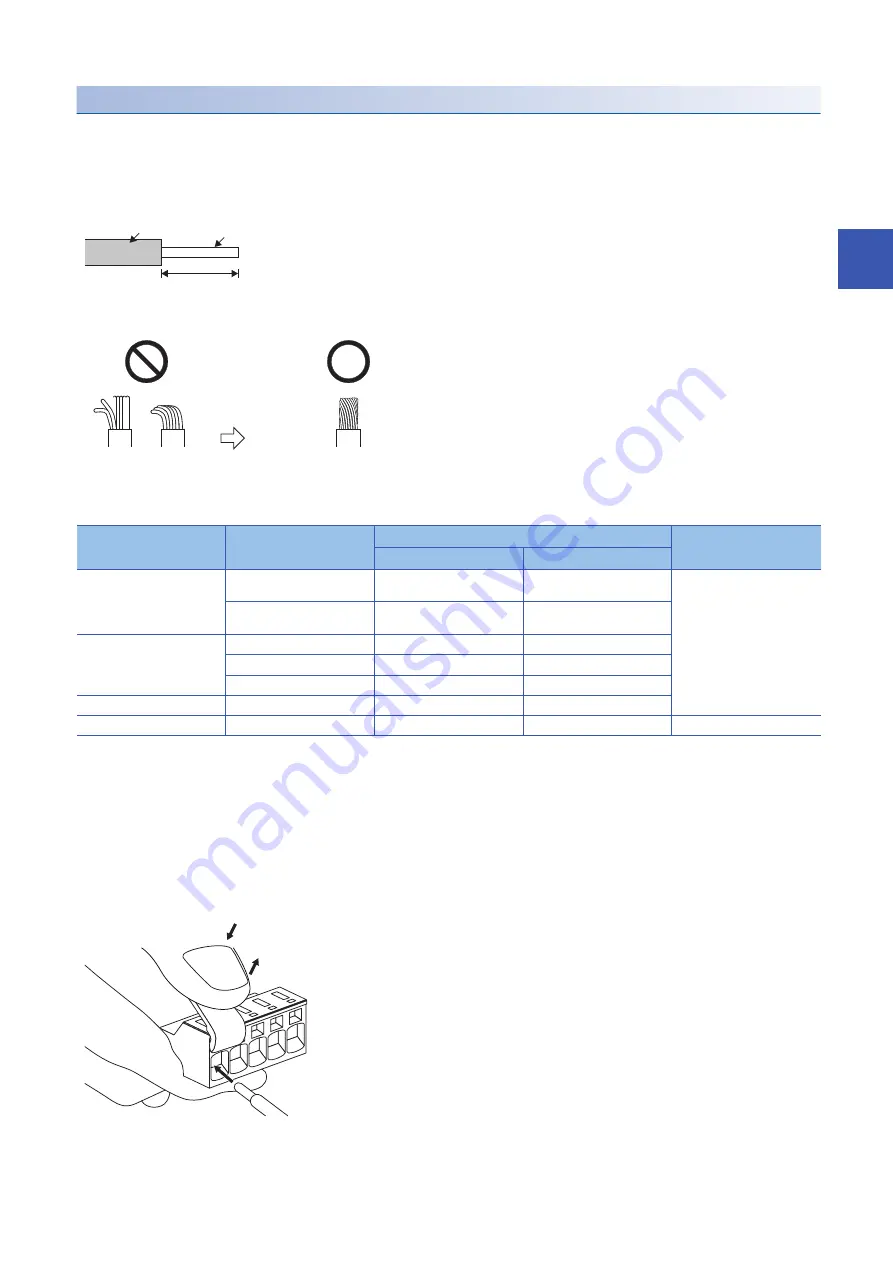

Fabricating the wire insulator

Refer to the following for the stripped length of the wire insulator. Set the appropriate length based on the wire type and

fabrication condition.

Twist the core wires lightly and straighten them as follows.

A ferrule can also be used when connecting to the connectors. If using a ferrule, choose from one of the ferrules and the

crimping tools shown below.

■

Inserting wire

Insert only one wire or ferrule into each wire insertion hole on each power connector.

Insert the open tool as follows and push it down to open the spring.

While the open tool is pushed down, insert the stripped wire into the wire insertion hole. Check the wire insertion depth so that

the wire insulator is not caught by the spring and that the conductive part of the stripped wire is not exposed.

Release the open tool to fix the wire. Pull the wire lightly to confirm that the wire is surely connected. In addition, confirm that

the ends of the core wires do not stick out of the connector.

Servo amplifier

Wire size

Ferrule model (Phoenix Contact)

Crimping tool (Phoenix

Contact)

For one wire

For two wires

MR-J5-10_ to

MR-J5-100_

MR-J5W2-_G_

MR-J5W3-_G_

AWG 16

AI 1,5 -10 BK

AI-TWIN 2X 1,5 -10 BK

CRIMPFOX-ZA3

AWG 14

AI 2,5 -10 BU

MR-J5-200_ to

MR-J5-350_

AWG 16

AI 1,5 -10 BK

AI-TWIN 2X 1,5 -10 BK

AWG 14

AI 2,5 -10 BU

AI-TWIN 2X 2,5 -10 BU

AWG 12

AI 4 -10 GY

MR-J5-500_

AWG 10

Al6-12 YE

MR-J5-700_

AWG 8

Al10-12 RD

CRIMPFOX-25R

Insulator

Core

Stripped length

Twist and straighten the strands.

Loose and bent strands

(1) Push down the open tool.

(3) Release the open tool to fix the wire.

(2) Insert the wire.

Summary of Contents for Melservo-J5 MR-J5 Series

Page 2: ......

Page 441: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 439 12 MEMO ...

Page 445: ......