10 USING A LINEAR SERVO MOTOR

10.3 Startup [A]

329

10

Magnetic pole detection

Outline of magnetic pole detection

Before the positioning operation of the linear servo motor, perform the magnetic pole detection. When [Pr. PL01] is set to the

initial value, perform magnetic pole detection only at the first servo-on after the power is turned on.

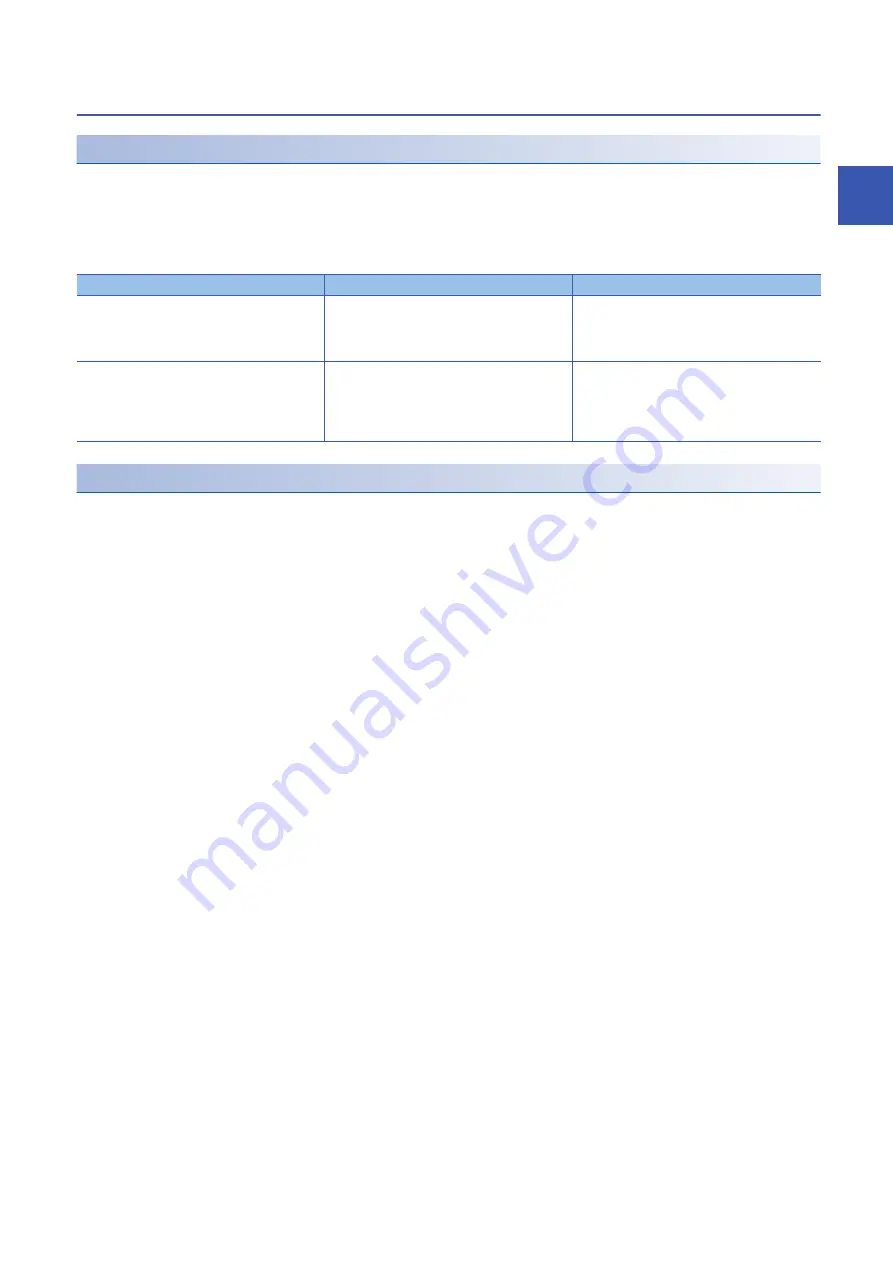

The magnetic pole detection includes the following two methods. Each method has advantages and disadvantages. Select a

magnetic pole detection method suitable for the usage.

In the initial value, the position detection method is selected.

Precautions on magnetic pole detection

• For the magnetic pole detection, the linear servo motor automatically starts to move simultaneously with turning-on of the

servo-on command.

• If the magnetic pole detection is not executed properly, the linear servo motor may operate unexpectedly.

• Establish the machine configuration to use LSP (Forward rotation stroke end) and LSN (Reverse rotation stroke end). The

machine may be damaged due to a collision without LSP and LSN.

• Assign LSP and LSN, and perform the magnetic pole detection also in the torque mode.

• At the magnetic pole detection, whether the direct drive motor moves in the positive or negative direction is unpredictable.

• Depending on the setting value of [Pr. PL09 Magnetic pole detection - Voltage level], an overload, overcurrent, magnetic

pole detection alarm, or others may occur.

• When performing the positioning operation from a controller, use the sequence which confirms the normal completion of the

magnetic pole detection and the servo-on status, then outputs the positioning command. If the controller outputs the

positioning command before RD (Ready) turns on, the command may not be accepted or an alarm may occur.

• If the linear encoder is installed incorrectly, an alarm may occur.

• If the linear encoder resolution setting ([Pr. PL02 Linear encoder resolution setting - Numerator] and [Pr. PL03 Linear

encoder resolution setting - Denominator]) or the setting value of [Pr. PL09] is incorrect, an alarm may occur.

• For the machine whose friction becomes 30 % or more of the continuous thrust, the direct drive motor may not operate

properly after the magnetic pole detection.

• For the horizontal shaft of the machine whose unbalanced thrust becomes 20 % or more of the continuous thrust, the direct

drive motor may not operate properly after the magnetic pole detection.

• The magnetic pole detection may fail if performed simultaneously with multiple axes connected to each other (e.g. a

tandem configuration). Perform the magnetic pole detection for each axis. At this time, set the axes for which the magnetic

pole detection is not performed to servo-off.

• During the magnetic pole detection, the value of [Pr. PE47 Unbalanced torque offset] is regarded as "0".

• When detecting magnetic poles on the vertical axis, use a counterweight or the like to prevent the linear servo motor from

moving with the force of gravity.

Magnetic pole detection

Advantage

Disadvantage

Position detection method

1. The magnetic pole detection has a high degree

of accuracy.

2. The adjustment procedure at the magnetic pole

detection is simple.

1. The travel distance at the magnetic pole

detection is long.

2. For equipment with small friction, the initial

magnetic pole detection error may occur.

Minute position detection method

1. The travel distance at the magnetic pole

detection is short.

2. Even for equipment with small friction, the

magnetic pole detection is available.

1. The adjustment procedure at the magnetic pole

detection is complex.

2. If a disturbance occurs during the magnetic pole

detection, [AL. 027 Initial magnetic pole

detection error] may occur.

Summary of Contents for Melservo-J5 MR-J5 Series

Page 2: ......

Page 441: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 439 12 MEMO ...

Page 445: ......