4. STARTUP

4 - 8

(2) How to find the cause of position shift

Encoder

Q

P

C

M

L

(b) Cumulative command pulses

(c) Cumulative feedback pulses

(d) Machine stop position M

Cause B

(a) Output pulse

counter

Cause A

SON (Servo-on) input

LSP/LSN (Stroke end) input

Servo amplifier

Controller

Servo motor

Machine

Electronic gear

[Pr.PA05], [Pr.PA06],

[Pr.PA07], [Pr.PA21]

Cause C

When a position shift occurs, check (a) output pulse counter Q, (b) cumulative command pulse P, (c)

cumulative feedback pulse C, and (d) machine stop position M in the above diagram.

Also, Causes A, B, and C indicate the causes of position mismatch. For example, Cause A indicates that

noise entered the wiring between the controller and servo amplifier, causing command input pulses to be

miscounted.

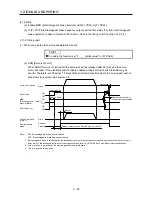

In a normal status without position shift, there are the following relationships.

1) Q = P (Output counter = Cumulative command pulses)

2) When [Pr. PA21] is "0 _ _ _"

P •

CMX [Pr. PA06]

CDV [Pr. PA07]

= C (Cumulative command pulses × Electronic gear = Cumulative feedback

pulses)

3) When [Pr. PA21] is "1 _ _ _"

P •

131072

FBP [Pr. PA05]

= C

4) C •

ǻƐ

= M (Cumulative feedback pulses × Travel distance per pulse = Machine position)

Check for a position mismatch in the following sequence.

1) When Q

P

Noise entered the pulse train signal wiring between the controller and servo amplifier, causing

command input pulses to be miscounted. (Cause A)

Make the following check or take the following measures.

Check how the shielding is done.

Change the open collector type to the differential line driver type.

Run wiring away from the power circuit.

Install a data line filter. (Refer to section 11.9 (2) (a).)

Change the [Pr. PA13 Command pulse input form] setting.

Summary of Contents for MELSERVO-JE MR-JE-100A

Page 23: ...1 FUNCTIONS AND CONFIGURATION 1 12 MEMO ...

Page 29: ...2 INSTALLATION 2 6 MEMO ...

Page 91: ...3 SIGNALS AND WIRING 3 62 MEMO ...

Page 171: ...5 PARAMETERS 5 44 MEMO ...

Page 195: ...6 NORMAL GAIN ADJUSTMENT 6 24 MEMO ...

Page 221: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 26 MEMO ...

Page 249: ...8 TROUBLESHOOTING 8 28 MEMO ...

Page 255: ...9 DIMENSIONS 9 6 MEMO ...

Page 263: ...10 CHARACTERISTICS 10 8 MEMO ...

Page 293: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 30 MEMO ...