1. Features

The extension kit is a dedicated part for the electronic sewing machine PLK-G1010 standard

specifications, and is used to extend the sewing area in the X axis direction by 110mm. This kit is

configured of the X axis table mechanism part, clamp mechanism part and parts for the sewing

machine including the slide plate and reinforcement support parts, etc.

The pneumatic pressure control device for changing the magnetic type work clamp, mounted as a

standard on the sewing machine, to the pneumatic type clamp is enclosed, so the force for clamping

the material to be stitched can be increased, and the clamping speed can also be adjusted.

2. Specifications

Name

:

MP-G10-EX (Extension Kit)

Applicable model:

:

PLK-G1010

Sewing area

:

210 (X) mm X 100 (Y) mm

Clamp UP position

:

30 mm

Pressing operation

:

Use foot switch normally provided with the electronic

sewing machine

Drive source air

pressure

Primary side

:

0.5 MPa

(

5 kgf /cm

2

)

or more

Secondary side:

:

0.4 MPa

(

4 kgf /cm

2

)

Trouble such as operation errors could occur if the secondary pressure is set too high.

Use within the range of 0.4 MPa (4 kgf /cm

2

).

CAUTION

- 1 -

Summary of Contents for MP-G10-EX

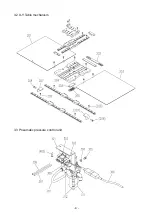

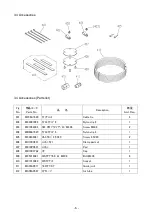

Page 6: ...3 2 X Y Table mechanism 3 3 Pneumatic pressure control unit 4 ...

Page 14: ...MEMO ...

Page 15: ...MEMO ...

Page 16: ...Printed in Japan ...