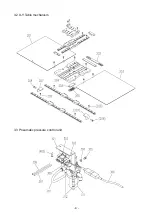

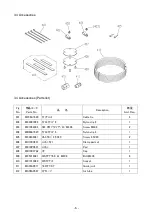

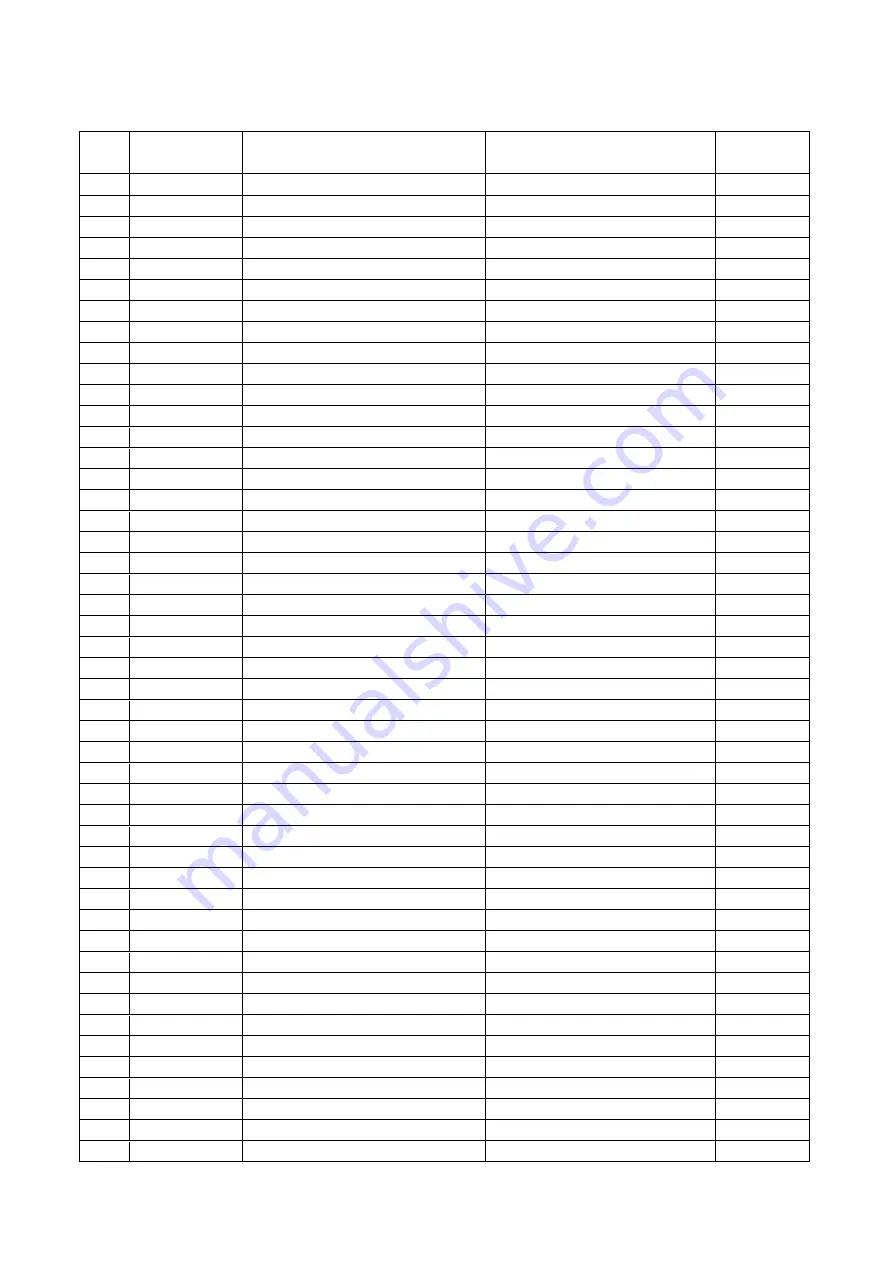

3.1 Clamp mechanism (Parts list)

Fig

部品コード

品

名

Description

数量

No.

Parts No.

Amt. Req.

101

M91055020

ロッカクアナツキトメネジ

M4X4

Screw M4X4

4

102

MH10A0352

カラー

Collar

2

103

M90519050

ナイロンワッシャ

Nylon washer

4

104

M91109002

ヒラネジ

11/64(40)X7

Screw 11/64(40)X7

2

105

M90421050

ザガネ

4

Washer 4

10

106

MH10K0950

レバー

(S2L)

Lever (S2L)

1

107

MH10K1950

レバー

(S1)

Lever (S1)

2

108

M90538060

ナックルピン

(L)

Knuckle pin (L)

1

109

ME10P0434

エアシリンダ

Air cylinder

2

110

ME10P0352

カラー

Collar

2

111

M93004021

ロッカクアナツキボルト

M3X5

Socket bolt M3X5

4

112

MH10A0308

オサエダイ

Clamp bracket

1

113

MH10K0601

シリンダトリツケイタ

Cylinder bracket

1

114

M94002017

セフティソケット

M4X8

Safety socket bolt M4X8

4

115

M90555060

ピン

Pin

1

116

M90548060

ナックルピン

(R)

Knuckle pin (R)

1

117

MH10K2950

レバー

(S2R)

Lever (S2R)

1

118

M90822060

ピン

Pin

1

119

MB10X0455

ジクササエ

Shaft holder

1

120

MB10X0454

ジク

Shaft

1

121

M90804003

マルヒラネジ

1/8(44)X4

Screw 1/8(44)X4

4

122

M94003017

セフティソケット

M3X6

Safety socket bolt M3X6

2

123

MH10A4477

ストッパ

Stopper

2

124

M94008070

ローラリテーナ

Roller retainer

4

125

M94019017

セフティソケット

M4X14

Safety socket bolt M4X14

6

126

MH10A2957

オサエコテイレース

Fixed race

2

127

MH10A3957

オサエイドウレース

Movable race

2

128

MH10A4957

オサエコテイレース

Fixed race

1

129

MH10A3601

オサエトリツケイタ

Clamp foot

1

130

M95005017

セフティソケット

M5X10

Safety socket bolt M5X10

4

131

M94005022

ロッカクアナツキボタンボルト

M4X8

Bolt M4X8

2

132

M90422050

コザガネ

4

Washer 4

4

133

M94041021

ロッカクアナツキボタンボルト

M4X6

Bolt M4X6

2

134

MH10A0196

イチギメイタ

Guide plate

2

135

MH10X0105

オサエ

Clamp frame

1

136

MH10X0272

オクリイタ

Feed plate

1

137

MH10X0339

X

カバーイタ

(L)

X-cover plate (left)

1

138

MH10X1339

X

カバーイタ

(R)

X-cover plate (right)

1

139

MB10X2470

スベリイタ

Slide plate

1

140

MB10X0797

ホゴフィルム

Film sheet

1

141

M90990002

ヒラネジ

M4X8

Screw M4X8

8

142

MH10X0426

スベリイタササエ

(L)

Slide plate bracket (L)

1

143

MB62A4601

トリツケイタ

Mounting plate

4

144

M94007017

セフティソケット

M4X12

Safety socket bolt M4X12

4

145

MH10X1426

スベリイタササエ

(R)

Slide plate bracket (R)

1

146

M95002017

セフティソケット

M5X12

Safety socket bolt M5X12

4

147

M91004045

ナット

M4

Nut M4

4

- 3 -

Summary of Contents for MP-G10-EX

Page 6: ...3 2 X Y Table mechanism 3 3 Pneumatic pressure control unit 4 ...

Page 14: ...MEMO ...

Page 15: ...MEMO ...

Page 16: ...Printed in Japan ...