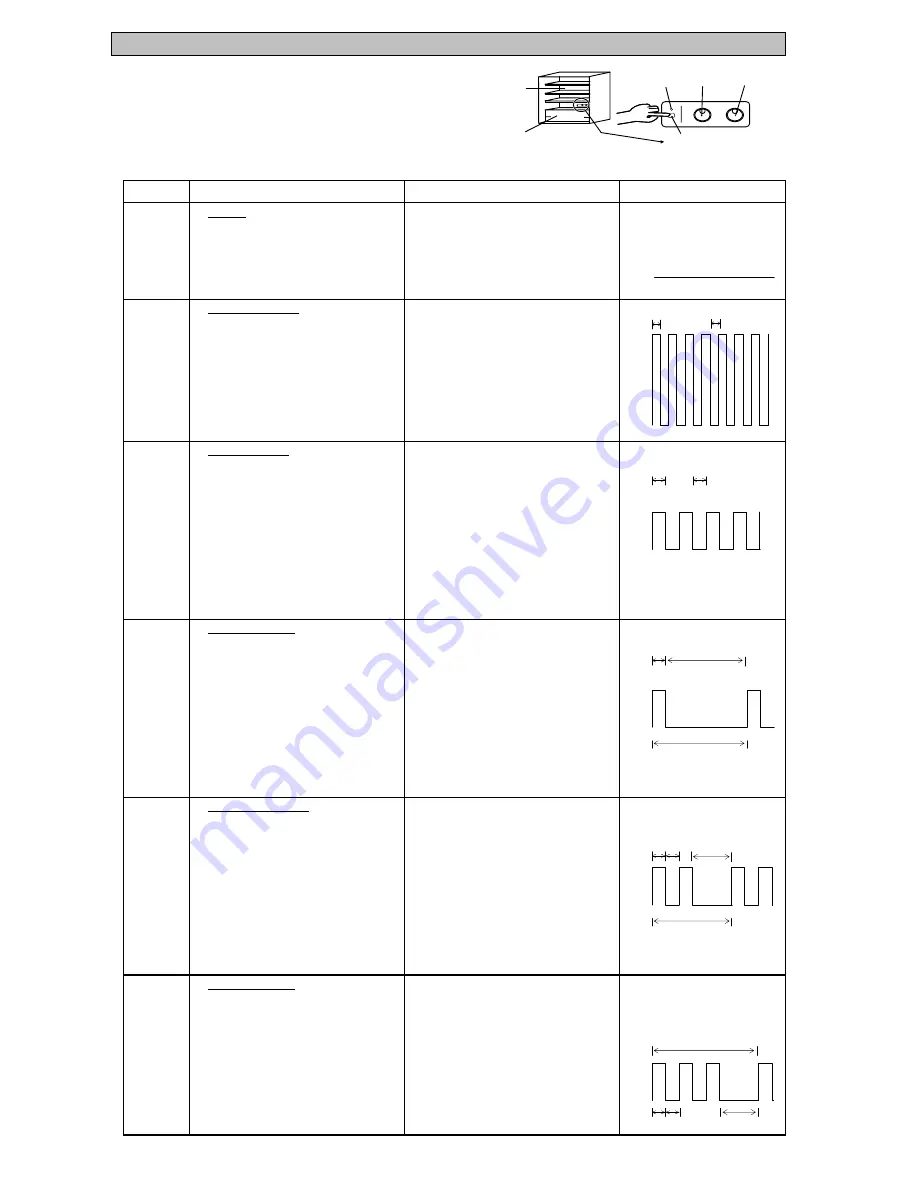

(3) LED trouble display and the check point

(3.1) LED trouble display : follow the procedure of "self check method

and its operation" at page 11. Trouble is indicated by the blinking number

of ice making stop LED.

∗

When several troubles occur, smaller blinking number of LEDs has to be indicated first.

(3.2) Check point and treatment

Normal

1. Normally display and the Auto ice-maker

system display.

* If non-power supply, it'll show as same

the effect.

Auto ice maker NG

1. The connector lead wire of Auto ice maker 1. Check all points of the Auto ice maker

is not orderly.

connector lead wire. May be un-lock

and struck insert.

2.

2.

3.

3. PCB plate ( Ref Con assy) NG

Thermistor(I) NG

1.

The connector thermistor (I) lead wire

1.

Check all points of the thermistor (I)

isn't orderly.

connector lead wire, may be unlock

and struck insert.

2.

Thermistor (I) NG (break or short)

2.

If the resistance of thermistor (I) is NG,

should be changed the thermistor and

re-check the resistance.

3.

PCB plate (Ref Con assay) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance).

Thermistor (F) NG

1. The connector thermistor (F) lead wire

1.

Check all points of the thermistor (F)

isn't orderly.

connector lead wire, may be unlock

and struck insert.

2. Thermistor (F) NG (break or short)

2.

If the resistance of thermistor (F) is

NG,should be changed the thermistor and

re-check the resistance.

3. PCB plate (Ref Con assy) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

Thermistor (DEF) NG

1. The connector DEF. thermistor lead wire

1.

Check all points of the thermistor

isn't orderly.

(DEF) connector lead wires, may be

unlock and struck insert.

2. Thermistor (DEF) NG (break or short)

2.

If the resistance of thermistor (DEF) is

NG,should be changed the thermistor and

re-check the resistance.

3. PCB plate (Ref Con assy) NG

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

Defrost heater NG

1.

1.

2. Defrost heater break or

2.

Thermal fuse break.

and thermal fuse.

3. PCB plate (Ref Con assy) break.

3.

If the resistance is OK,should be changed

PCB plate (Ref Con assy and re-check

the resistance.

isn't orderly.

maker.

Replace and re-check the PCB plate

and non-display)

connector lead wire, may be un-lock

Blink

Blink

Light

Light

Light

1 Blink

No Light

Display function of LED

Off

NO

Function

Explanation

Light

No Light

Detecting method and corrective NG points

2 Blinks

Check the resistance of the defrost heater

and struck insert.

3 Blinks

Light

No Light

No Light

No Light

0.1 second

0.3 seconds

No Light

Replace and re-check the Auto ice

( Ref Con assy)

Auto ice maker (Motor's not rotate

The Defrost heater connector lead wire

Check all points of the defrost heater

Light

0.1 sec

5 sec

1

1

5 sec

1

2

1

2

5 sec

1

2

1

3

1 Cycle

0.1 sec

0.3 sec

0.3 sec

0.3 sec

1 Cycle

0.3 sec

1 Cycle

0.3 sec

Slide room

Refrigerator room

Ice making

stop LED

Refrigerator Freezer

Ice maker off

16

Summary of Contents for MR-C375C-OB-A

Page 2: ......

Page 9: ... SKELETON WIRING DIAGRAM MR C375C A MR C375CL A MR C405C A MR C405CL A 3 WIRING DIAGRAM 7 ...

Page 12: ...MR C375C A MR C375CL A MR C405C A MR C405CL A 5 NAMES OF PARTS 10 ...

Page 26: ...DOOR BODY PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 8 PARTS LIST 24 ...

Page 28: ...BODY PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 26 ...

Page 30: ...ELECTRICIAL PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 28 ...

Page 32: ...ACCESSORY AND UNIT PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 30 ...