3 - 28

3. LOAD SIDE ENCODER

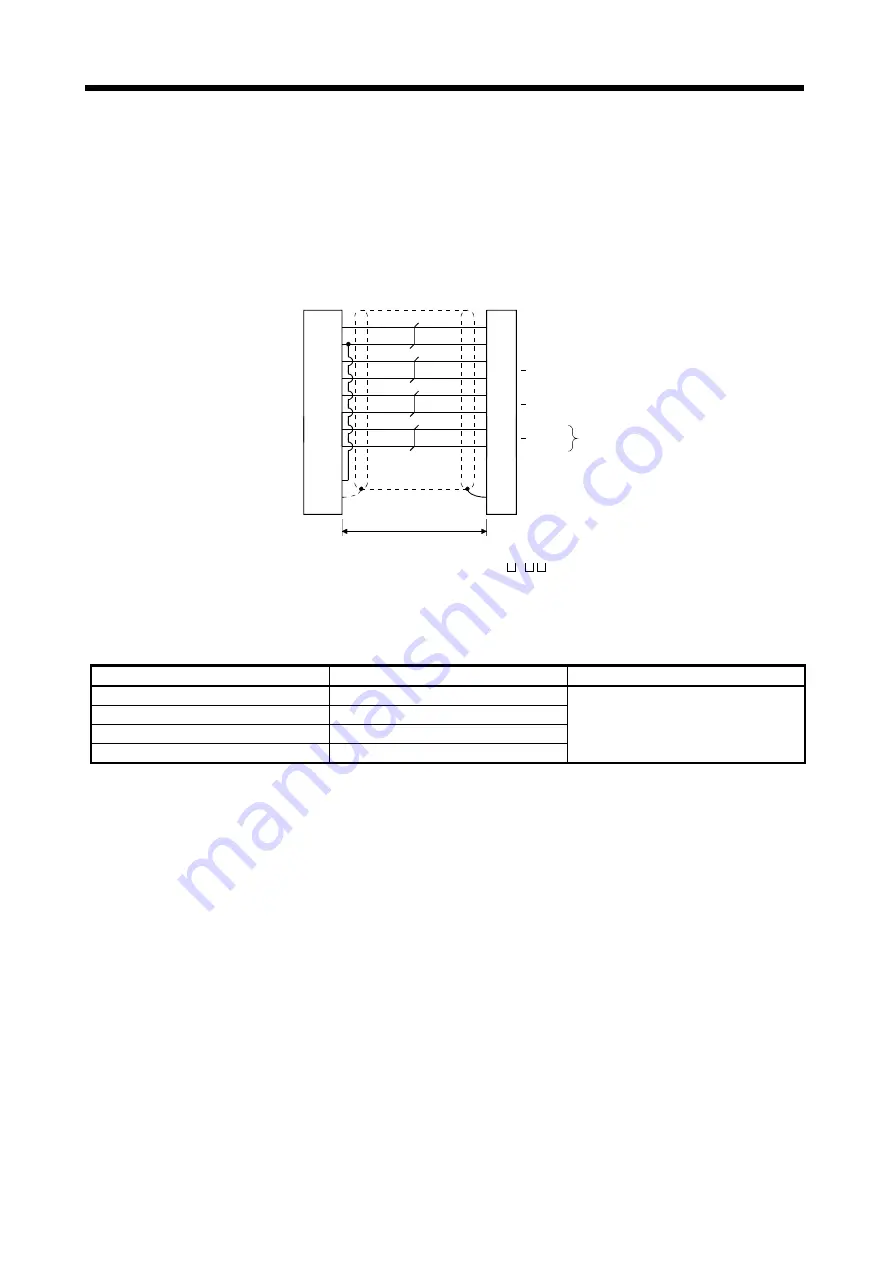

(3) Internal wiring diagram

For production of the load side encoder cable, use a cable durable against the long period of flexing action.

Even though the cable length is max. 30m for the RS-422 communication, the length may be shortened

due to the power supply voltage drop or the specifications of linear encoder.

A connection example is shown below. For details, contact with the encoder manufacturer.

1) When the consumption current of the load side encoder is 350mA or less

B-phase

P5

LG

1

2

PZ

PZR

7

8

Connector on

the servo amplifier side

ABZ-phase differential

output load side encoder

10

SD

Plate

5V

3

4

5

6

9

PA

PAR

PB

PBR

0V

A-phase

A-phase

B-phase

Z-phase

Z-phase

(Note 1)

30m or less

(Note 2)

Shield

PSE

(Note 3)

Note 1. For the load side encoder without Z-phase, set parameter No.PC27 to " 1

".

2. Securely connect a shield cable to the plate (ground plate) in the connector.

3. The following table shows the cable size to be used and the number of paired connections of LG and P5 when the consumption

current of the load side encoder is 350mA. When the consumption current of the load side encoder is 350mA or less, the paired

connections can be decreased.

Wiring length

Number of LG and P5 connections

Cable size

to 5m

2-pair

to 10m

3-pair

to 20m

6-pair

to 30m

8-pair

AWG22

Summary of Contents for MR-J3-B-RJ006

Page 15: ...A 14 MEMO ...

Page 19: ...4 MEMO ...

Page 65: ...2 18 2 SIGNALS AND WIRING MEMO ...

Page 119: ...4 22 4 OPERATION AND FUNCTIONS MEMO ...

Page 145: ...6 6 6 TROUBLESHOOTING MEMO ...

Page 155: ...7 10 7 OUTLINE DRAWINGS MEMO ...

Page 165: ...SH NA 030056 C ...