11. OPTIONS AND PERIPHERAL EQUIPMENT

11 - 23

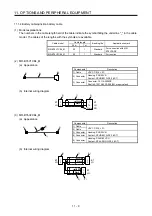

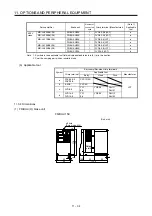

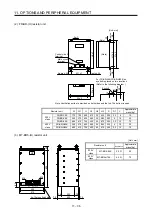

(6) MR-RB1H-4

[Unit: mm]

156

168

144

6

2

149

173

6

Approx. 6

Approx. 24

6

15

φ

6 mounting hole

36

40

TE1 terminal

P

C

G3

G4

Applicable wire size: AWG 24 to 10

Tightening torque: 0.5 to 0.6 [N•m]

Mounting screw

Screw size: M5

Tightening torque: 3.24 [N•m]

Mass: 1.1 [kg]

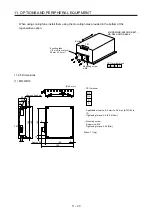

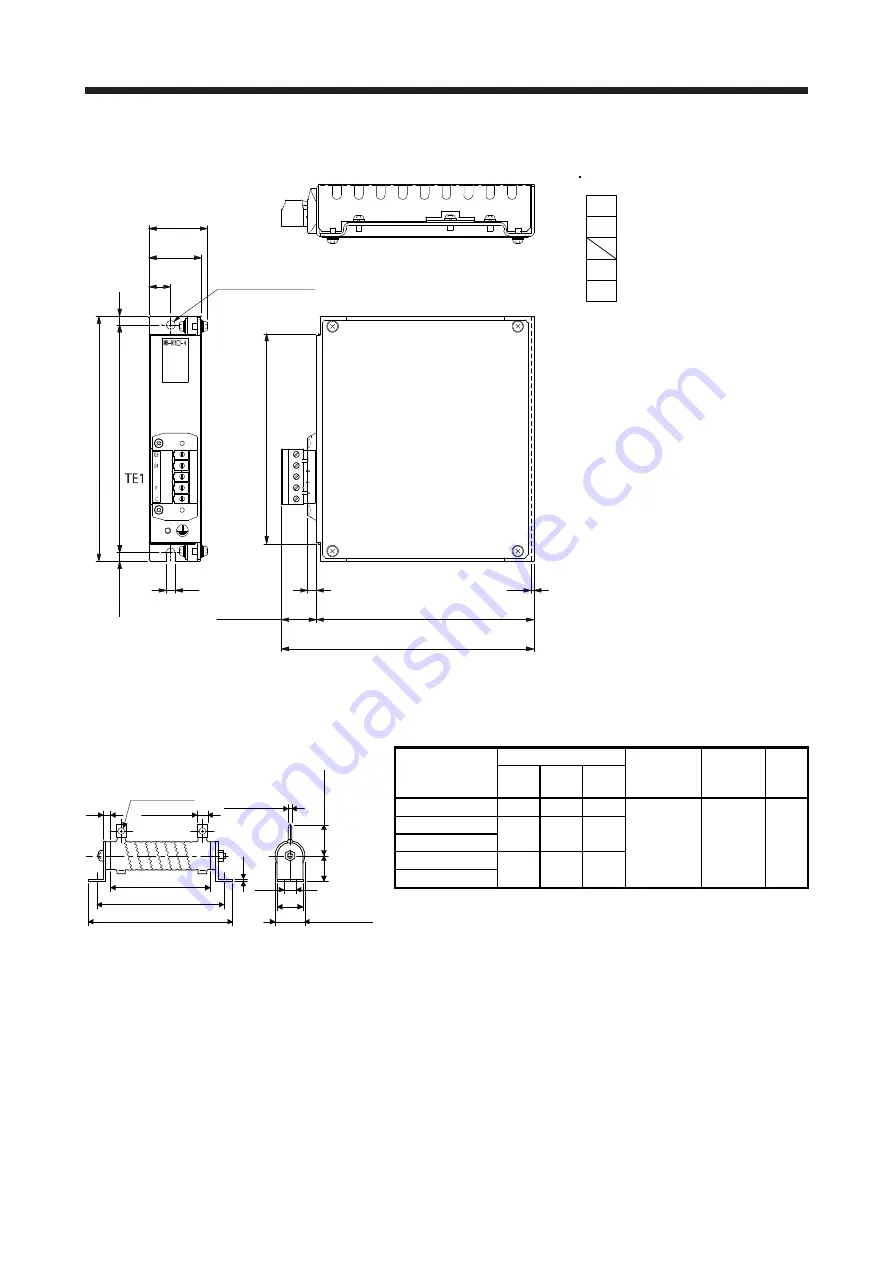

(7) GRZG400-0.8

Ω

/GRZG400-0.6

Ω

/GRZG400-0.5

Ω

/GRZG400-2.5

Ω

/GRZG400-2.0

Ω

(standard

accessories)

[Unit: mm]

Appr

ox. K

1.6

Approx.

φ

47

9.5

40

411

385

10

Approx.

φ

C

Approx. A

Approx. 2.4

40

Approx. 330

Regenerative

resistor

Variable dimensions

Mounting

screw size

Tightening

torque

[N•m]

Mass

[kg]

A C K

GRZG400-0.8

Ω

10 5.5 39

M8 13.2

0.8

GRZG400-0.6

Ω

16 8.2 46

GRZG400-0.5

Ω

GRZG400-2.5

Ω

10 5.5 39

GRZG400-2.0

Ω

Summary of Contents for MR-J4-100B(-RJ)

Page 17: ...8 MEMO ...

Page 143: ...4 STARTUP 4 20 MEMO ...

Page 199: ...5 PARAMETERS 5 56 MEMO ...

Page 227: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 281: ...8 TROUBLESHOOTING 8 16 MEMO ...

Page 303: ...9 DIMENSIONS 9 22 MEMO ...

Page 319: ...10 CHARACTERISTICS 10 16 MEMO ...

Page 429: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 110 MEMO ...

Page 435: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 6 MEMO ...

Page 483: ...14 USING A LINEAR SERVO MOTOR 14 34 MEMO ...

Page 531: ...16 FULLY CLOSED LOOP SYSTEM 16 26 MEMO ...

Page 613: ...17 APPLICATION OF FUNCTIONS 17 82 MEMO ...

Page 654: ...APPENDIX App 41 ...