2. INSTALLATION

2 - 3

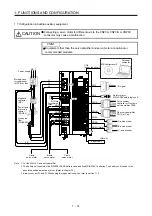

2.2 Keep out foreign materials

(1) When drilling in the cabinet, prevent drill chips and wire fragments from entering the servo amplifier.

(2) Prevent oil, water, metallic dust, etc. from entering the servo amplifier through openings in the cabinet or

a cooling fan installed on the ceiling.

(3) When installing the cabinet in a place where toxic gas, dirt and dust exist, conduct an air purge (force

clean air into the cabinet from outside to make the internal pressure higher than the external pressure) to

prevent such materials from entering the cabinet.

2.3 Encoder cable stress

(1) The way of clamping the cable must be fully examined so that bending stress and cable's own weight

stress are not applied to the cable connection.

(2) For use in any application where the servo motor moves, fix the cables (for the encoder, power supply,

and brake) with having some slack from the connector connection part of the servo motor to avoid

putting stress on the connector connection part. Use the optional encoder cable within the bending life

range. Use the power supply and brake wiring cables within the bending life of the cables.

(3) Avoid any probability that the cable insulator might be cut by sharp chips, rubbed by a machine corner or

stamped by workers or vehicles.

(4) For the cable installation on a machine where the servo motor moves, the bending radius should be

made as large as possible. Refer to section 10.4 for the bending life.

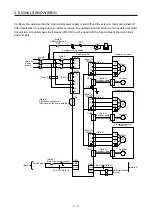

2.4 SSCNET III cable laying

SSCNET III cable is made from optical fiber. If optical fiber is added a power such as a major shock, lateral

pressure, haul, sudden bending or twist, its inside distorts or breaks, and optical transmission will not be

available. Especially, as optical fiber for MR-J3BUS_M/MR-J3BUS_M-A is made of synthetic resin, it melts

down if being left near the fire or high temperature. Therefore, do not make it touched the part, which can

become hot, such as heat sink or regenerative option of servo amplifier.

Read described item in this section carefully and handle it with caution.

(1) Minimum bend radius

Make sure to lay the cable with greater radius than the minimum bend radius. Do not press the cable to

edges of equipment or others. For the SSCNET III cable, the appropriate length should be selected with

due consideration for the dimensions and arrangement of the servo amplifier. When closing the door of

cabinet, pay careful attention for avoiding the case that SSCNET III cable is held down by the door and

the cable bend becomes smaller than the minimum bend radius. For the minimum bend radius, refer to

section 11.1.2.

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...