15. USING A DIRECT DRIVE MOTOR

15 - 11

(3) Operation at the magnetic pole detection

WARNING

Note that the magnetic pole detection automatically starts simultaneously with the

turning-on of the servo-on command.

CAUTION

If the magnetic pole detection is not executed properly, the direct drive motor may

operate unexpectedly.

POINT

Establish the machine configuration using FLS (Upper stroke limit) and RLS

(Lower stroke limit). Otherwise, the machine may be damaged due to a collision.

At the magnetic pole detection, whether the motor rotates in the forward or

reverse direction is unpredictable.

Depending on the setting value of [Pr. PL09 Magnetic pole detection voltage

level], an overload, overcurrent, magnetic pole detection alarm, or others may

occur.

When performing the positioning operation from a controller, use the sequence

which confirms the normal completion of the magnetic pole detection and the

servo-on status, then outputs the positioning command. If the controller outputs

the positioning command before RD (Ready) turns on, the command may not be

accepted or a servo alarm may occur.

After the magnetic pole detection, check the positioning accuracy with the test

operation (positioning operation function) of MR Configurator2.

The accuracy of the magnetic pole detection improves with no load.

(a) Incremental system

POINT

For the incremental system, the magnetic pole detection is required every time

the power is turned on.

By turning on the servo-on command from the controller after the power-on, the magnetic pole

detection is automatically carried out. Therefore, there is no need to set the parameter (first digit of

[Pr. PL01]) for executing the magnetic pole detection.

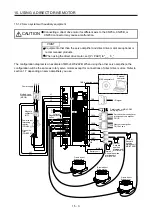

1) Timing chart

15 s or less

ON

OFF

ON

OFF

ON

OFF

95 ms

Servo-on command

Base circuit

RD (Ready)

Magnetic pole detection time (Note)

Note. The magnetic pole detection time indicates the operation time when FLS (Upper

stroke limit) and RLS (Lower stroke limit) are on.

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...