16. FULLY CLOSED LOOP SYSTEM

16 - 12

(5) Confirmation of load-side encoder position data

Check the load-side encoder mounting and parameter settings for any problems.

POINT

Depending on the check items, MR Configurator2 may be used.

Refer to section 16.3.6 for the data displayed on the MR Configurator2.

When checking the following items, the fully closed loop control mode must be set. For the setting of

control mode, refer to (2) in this section.

No.

Check item

Confirmation method and description

1

Read of load-side encoder position

data

With the load-side encoder in a normal state (mounting, connection, etc.), the load-side

cumulative feedback pulses value is counted normally when the load-side encoder is

moved.

When it is not counted normally, the following factors can be considered.

1. An alarm occurred.

2. The installation of the load-side encoder was not correct.

3. The encoder cable was not wired correctly.

2

Read of load-side encoder home

position (reference mark, Z-phase)

With the home position (reference mark, or Z-phase) of the load-side encoder in a normal

condition (mounting, connection, etc.), the value of load-side encoder information 1 is

cleared to 0 when the home position (reference mark, or Z-phase) is passed through by

moving the load-side encoder.

When it is not cleared, the following factors can be considered.

1. The installation of the load-side encoder was not correct.

2. The encoder cable was not wired correctly.

3

Confirmation of load-side encoder

feedback direction

(Setting of load-side encoder

polarity)

Confirm that the directions of the cumulative feedback pulses of servo motor encoder (after

gear) and the load-side cumulative feedback pulses are matched by moving the device

(load-side encoder) manually in the servo-off status. If mismatched, reverse the polarity.

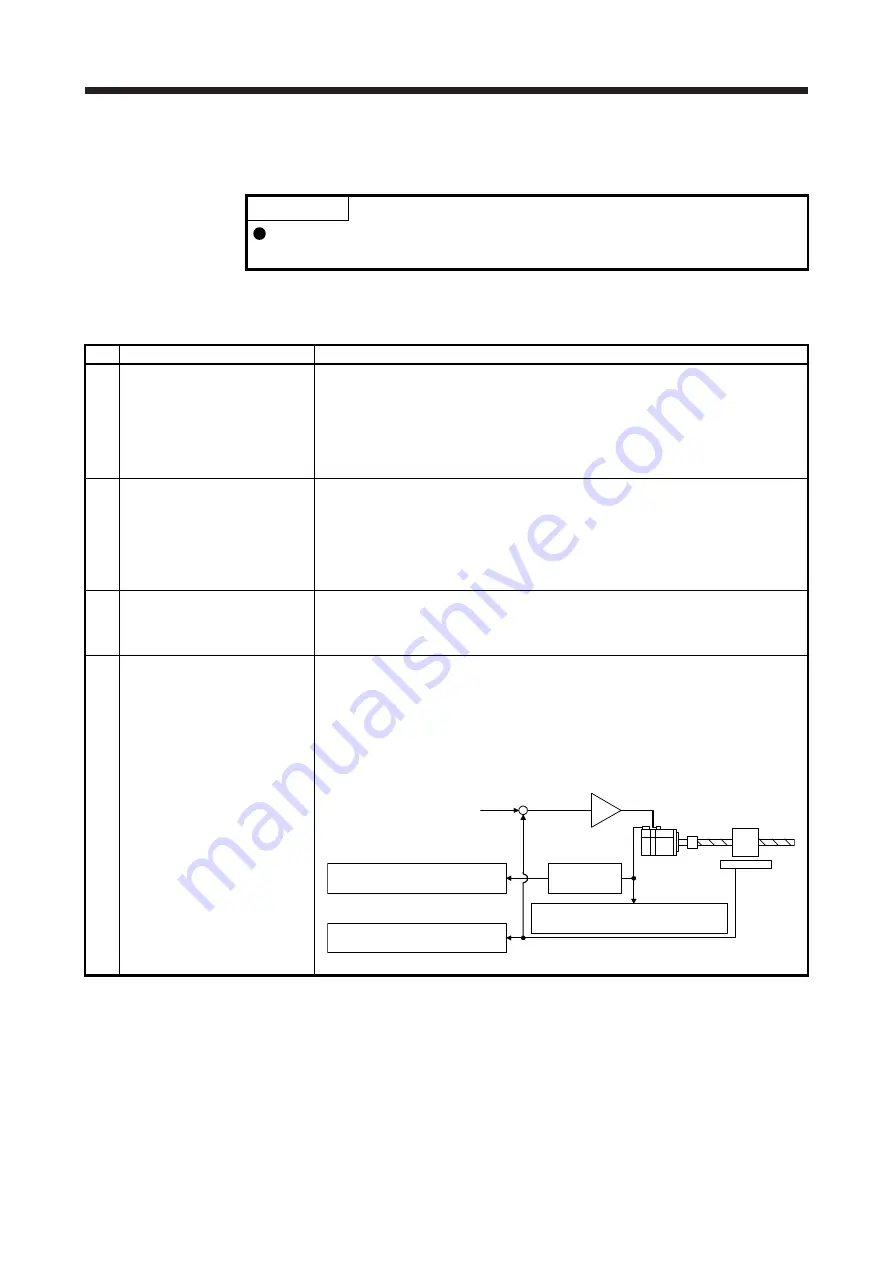

4

Setting of load-side encoder

electronic gear

When the servo motor and load-side encoder operate synchronously, the servo motor-side

cumulative feedback pulses (after gear) and load-side cumulative feedback pulses are

matched and increased.

If mismatched, review the setting of fully closed loop control feedback electronic gear ([Pr.

PE04], [Pr. PE05], [Pr. PE34], and [Pr. PE35]) with the following method.

1) Check the servo motor-side cumulative feedback pulses (before gear).

2) Check the load-side cumulative feedback pulses.

3) Check that the ratio of above 1) and 2) has been that of the feedback electronic gear.

Servo motor

Linear

encoder

+

-

Servo motor-side cumulative

feedback pulses (after gear)

3) Electronic

gear

2) Load-side cumulative

feedback pulses

Command

1) Servo motor-side cumulative

feedback pulses (before gear)

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...