3. SIGNALS AND WIRING

3 - 6

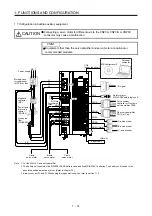

Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the

protective earth (PE) of the cabinet.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output

signals, disabling EM2 (Forced stop 2) and other protective circuits.

3. If the controller does not have forced stop function, always install the forced stop 2 switch (Normally closed contact).

4. When starting operation, always turn on EM2 (Forced stop 2). (Normally closed contact)

5. Use SW1DNC-MRC2-_. (Refer to section 11.4.)

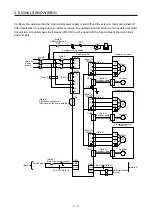

6. Use SSCNET III cables listed in the following table.

Cable

Cable model

Cable length

Standard cord inside

panel

MR-J3BUS_M

0.15 m to 3 m

Standard cable

outside panel

MR-J3BUS_M-A

5 m to 20 m

Long-distance cable

MR-J3BUS_M-B

30 m to 50 m

7. The wiring after the second servo amplifier is omitted.

8. Up to 64 axes of servo amplifiers can be connected. The number of connectable axes depends on the controller you use.

Refer to section 4.3 for setting of axis selection.

9. Make sure to cap the unused CN1B connector.

10. Supply 24 V DC ± 10% for interfaces from outside. Set the total current capacity to 350 mA for MR-J4W2-_B and to 450 mA for

MR-J4W3-_B. The 24 V DC power supply can be used both for input signals and output signals. 350 mA and 450 mA are the

values applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of I/O points.

Refer to section 3.8.2 (1) that gives the current value necessary for the interface. The illustration of the 24 V DC power supply

is divided between input signal and output signal for convenience. However, they can be configured by one.

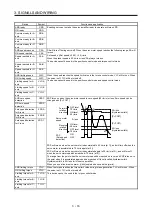

11. CALM (AND malfunction) turns on in normal alarm-free condition. (Normally closed contact)

12. In the initial setting, CINP (AND in-position) is assigned to the pin. You can change devices of the pin with [Pr. PD08].

13. You can change devices of these pins with [Pr. PD07] and [Pr. PD09].

14. Devices can be assigned for these devices with controller setting. For devices that can be assigned, refer to the controller

instruction manual. These assigned devices are for R_MTCPU, Q17_DSCPU, RD77MS_, QD77MS_, and LD77MS_.

15. Configure up a circuit to turn off EM2 when the main circuit power is turned off to prevent an unexpected restart of the servo

amplifier.

16. When not using the STO function, attach a short-circuit connector supplied with a servo amplifier.

17. The pin is not used for MR-J4 2-axis servo amplifiers.

18. For the MR-J4 3-axis servo amplifier

19. This signal cannot be used for MR-J4W3-_B.

20. When you use a linear servo motor or direct drive motor, use MBR (Electromagnetic brake interlock) for an external brake

mechanism.

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...