APPENDIX

App. - 36

App. 5.12 Dimensions

[Unit: mm]

Rating plate

5

182

5

192

5

FG

9.75

φ

5 mounting hole

12

168

6

86

80

2-M4 screw

Approx. 22.5

9.75

Approx. 192

Approx. 5

Approx. 5

182

Approx. 80

Mounting hole process drawing

19.5

22.5

7

8

7

8

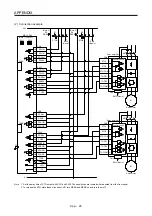

TOF2A

TOF1A

TOF2B

TOF1B

5

6

5

6

STO2A- STO2A+

STO2B- STO2B+

3

4

3

4

STO1A+

STO1B+

1

2

1

2

STO1A-

STO1B-

1A

1B

1A

1B

SDI1A+

SDI1A-

SRESA+ SRESA-

2A

2B

2A

2B

SDI1B+

SDI1B-

SRESB+ SRESB-

3A

3B

3A

3B

SDO1B+ SDO1B-

SDI2A+

SDI2A-

4A

4B

4A

4B

SDO1A+ SDO1A-

SDI2B+

SDI2B-

5A

5B

SDO2B+ SDO2B-

6A

6B

SDO2A+ SDO2A-

7A

7B

+24 V

0 V

8A

8B

TOFA

TOFB

CN8A

CN8B

Assignment

CN9

CN10

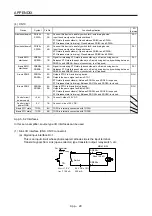

Mounting screw

Screw size: M4

Tightening torque: 1.2 N•m

Mass: 0.2 [kg]

Summary of Contents for MR-J4W2-0303B6

Page 39: ...2 INSTALLATION 2 8 MEMO ...

Page 97: ...4 STARTUP 4 20 MEMO ...

Page 181: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 235: ...9 DIMENSIONS 9 6 MEMO ...

Page 245: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 309: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 365: ...15 USING A DIRECT DRIVE MOTOR 15 24 MEMO ...

Page 389: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 461: ...17 APPLICATION OF FUNCTIONS 17 72 MEMO ...

Page 556: ...APPENDIX App 41 ...

Page 585: ...MEMO ...