6. NORMAL GAIN ADJUSTMENT

6 - 16

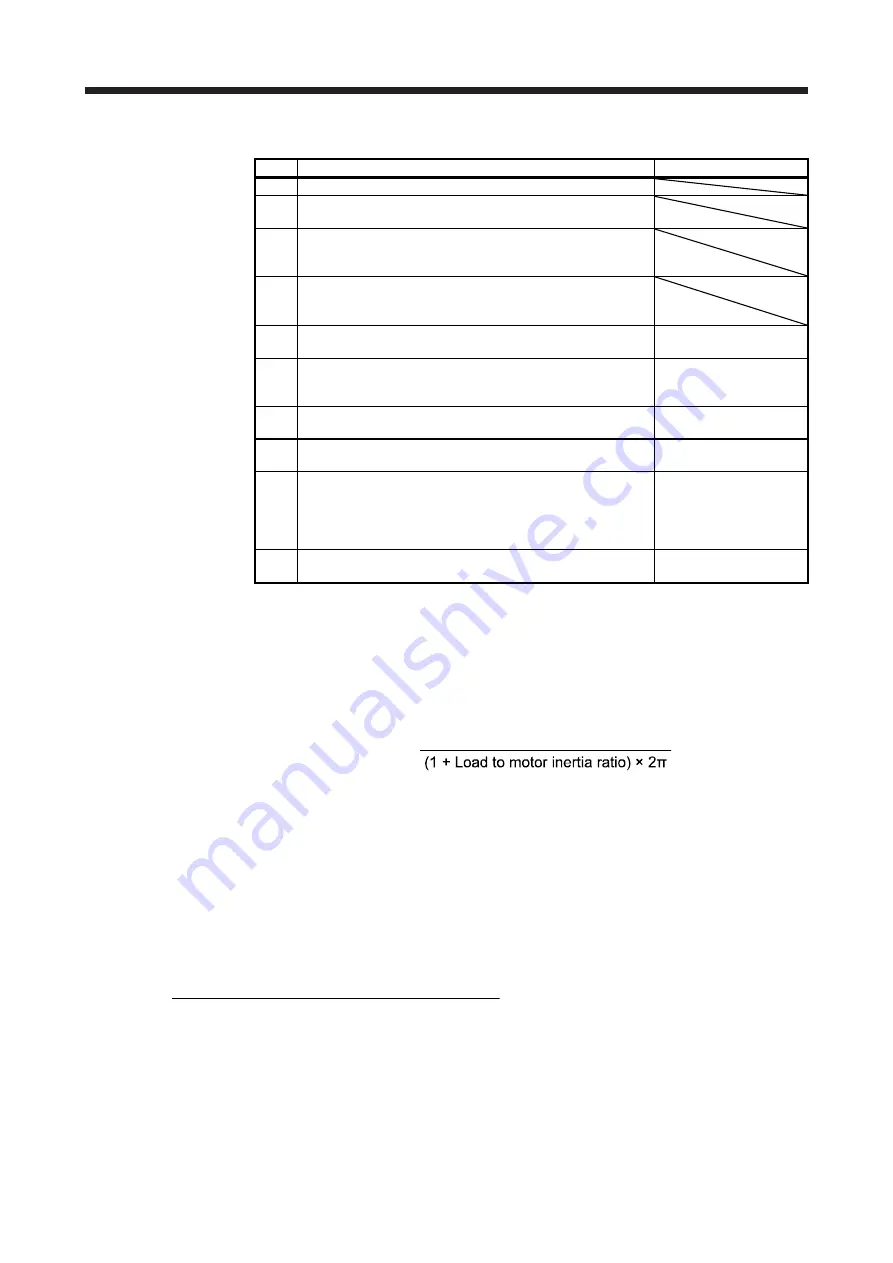

(b) Adjustment procedure

Step Operation

Description

1

Brief-adjust with auto tuning. Refer to section 6.2.3.

2

Change the setting of auto tuning to the manual mode ([Pr.

PA08]: _ _ _ 3).

3

Set the estimated value to the load to motor inertia ratio/load to

motor mass ratio. (If the estimate value with auto tuning is

correct, setting change is not required.)

4

Set a slightly smaller value to the model loop gain and the

position loop gain.

Set a slightly larger value to the speed integral compensation.

5

Increase the speed loop gain within the vibration- and unusual

noise-free range, and return slightly if vibration takes place.

Increase the speed loop

gain.

6

Decrease the speed integral compensation within the vibration-

free range, and return slightly if vibration takes place.

Decrease the time

constant of the speed

integral compensation.

7

Increase the position loop gain, and return slightly if vibration

takes place.

Increase the position loop

gain.

8

Increase the model loop gain, and return slightly if overshoot

takes place.

Increase the model loop

gain.

9

If the gains cannot be increased due to mechanical system

resonance or the like and the desired response cannot be

achieved, response may be increased by suppressing resonance

with the adaptive tuning mode or machine resonance

suppression filter and then executing steps 3 to 8.

Suppression of machine

resonance

Refer to section 7.2 and

7.3.

10

While checking the settling characteristic and motor status, fine-

adjust each gain.

Fine adjustment

(c) Parameter adjustment

1) [Pr. PB09 Speed loop gain]

This parameter determines the response level of the speed control loop. Increasing this value

enhances response but a too high value will make the mechanical system liable to vibrate. The

actual response frequency of the speed loop is as indicated in the following expression.

Speed loop response frequency [Hz] =

Speed loop gain

2) [Pr. PB10 Speed integral compensation]

To eliminate stationary deviation against a command, the speed control loop is under proportional

integral control. For the speed integral compensation, set the time constant of this integral

control. Increasing the setting lowers the response level. However, if the load to motor inertia

ratio is large or the mechanical system has any vibratory element, the mechanical system is liable

to vibrate unless the setting is increased to some degree. The guideline is as indicated in the

following expression.

Speed integral compensation setting [ms]

≥

2000 to 3000

Speed loop gain/(1 + Load to motor inertia ratio)

Summary of Contents for MR-J4W2

Page 9: ...A 8 MEMO ...

Page 17: ...8 MEMO ...

Page 31: ...1 FUNCTIONS AND CONFIGURATION 1 14 MEMO ...

Page 95: ...4 STARTUP 4 20 MEMO ...

Page 169: ...6 NORMAL GAIN ADJUSTMENT 6 20 MEMO ...

Page 201: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 32 MEMO ...

Page 213: ...8 TROUBLESHOOTING 8 12 MEMO ...

Page 219: ...9 OUTLINE DRAWINGS 9 6 MEMO ...

Page 229: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 295: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 327: ...14 USING A LINEAR SERVO MOTOR 14 32 MEMO ...

Page 371: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 521: ...APPENDIX App 38 ...

Page 537: ...MEMO ...

Page 541: ......