27

w

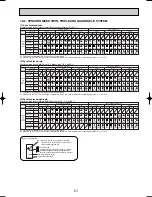

Press the remote controller’s CHECK button twice to perform self-diagnosis. See the table below for the

contents of LCD display.

LCD

Contents of inferior phenomena

P1

P2

P4

P5

P6

P8

P9

Abnormality of room temperature thermistor

Abnormality of pipe temperature thermistor/Liquid

Abnormality of drain sensor

Drain overflow protection is working.

Freezing/overheating protection is working.

Abnormality of pipe temperature

Abnormality of pipe temperature thermistor/Cond./Eva

LCD

Contents of inferior phenomena

U1~UP

F3~F9

E0~E5

E6~EF

----

FFFF

Malfunction outdoor unit

Malfunction outdoor unit

Remote controller transmitting error

Indoor/outdoor unit communication error

No error history

No applied unit

LED1 (microcomputer power supply)

LED2 (remote controller)

LED3

(indoor/outdoor communication)

Lits when power is supplied.

Remote controller

The indoor unit should be connected to the outdoor unit with address “0” setting.

Flash when indoor and outdoor unit are communicating.

See the table below for details of the LED display (LED 1, 2, 3) on the indoor controller circuit board.

13-2-2. Test run by outdoor unit SW4

The setting of test run (ON/OFF) and its operation mode (cooling/heating) can be set by SW4 on the controller circuit board of

outdoor unit. Check that SW5-1 is set to OFF before performing test run. If SW5-1 is set to ON, turn it OFF and then perform

test run. After finishing test run, set SW5-1 back to ON.

1

Set operation mode(cooling or heating) by SW4-2.

2

Start test run by setting SW4-1 to ON ( ) with the indicated operation mode of SW4-2.

3

Finish test run by setting SW4-1 to OFF ( ).

• Operation mode cannot be changed by SW4-2 during test run.

Stop test run to change operation mode by SW4-1, and restart test run by SW4-1 after

the mode is changed.

• Test run automatically stops 2 hours later by 2-hour OFF timer function.

• Test run can be performed by the remote controller.

• The remote controller display of test run by outdoor unit is the same as that of test run by

remote controller.

ON

SW4

1 2

A

Stop

B

Cooling

C

Operation

D

Heating

A

C D

B

(Factory setting)

OC317-1.qxp 04.11.26 9:33 AM Page 27